Frustrated with finding a dependable pogo pin manufacturer?

The wrong partner can mean poor quality and project delays.

Let me guide you to a trustworthy source.

To find a reliable pogo pin manufacturer, focus on specific criteria.

Prioritize manufacturers with proven quality control and relevant certifications.

Evaluate their capability for customization and their production efficiency to ensure project timelines are met.

Lastly, assess their commitment to customer support and technical assistance.

Choosing the right pogo pin or magnetic pogo pin connector manufacturer is vital for your product’s success.

It’s about more than just parts, it’s about partnership.

Let’s explore what makes a manufacturer truly reliable and how you can find one that meets your specific needs.

What Should You Know About Understanding Pogo Pins?

Are you new to pogo pins or unsure which type fits your project?

Making an uninformed choice can compromise your device.

Let’s clarify the essentials.

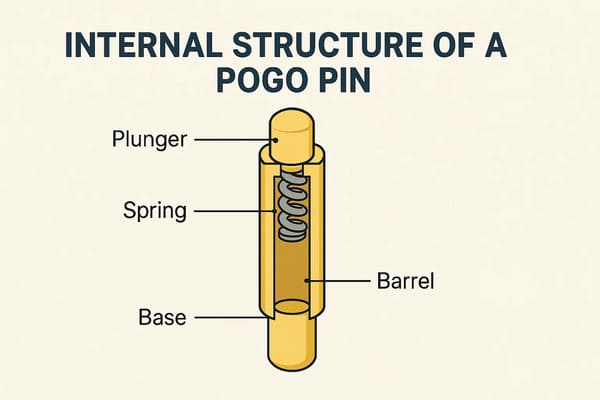

Understanding pogo pins involves knowing their function as spring-loaded electrical connectors.

Key aspects include their various types, such as those for high current or signal integrity, and critical specifications like contact resistance and durability.

Familiarity with these details helps ensure optimal performance in electronic applications.

Now that you understand the fundamental purpose and key characteristics of pogo pins, exploring the diverse range of available types can help you pinpoint the ideal solution for your specific electronic needs.

Different designs offer distinct advantages for various applications.

Types of Pogo Pins

Pogo pins come in many forms, each designed for specific needs.

Understanding these options helps in selecting the right fit for various applications.

- By Structure:

- Standard Pogo Pin: The basic design with a needle, spring, and tube.

- With Guide Pogo Pin: Ensures precise alignment.

- Sealed Pogo Pin: Offers water and dust resistance for harsh environments.

- By Needle Shape:

- Pointed Pogo Pin: For high-density connections.

- Flat Head Pogo Pin: For high current transmission.

- Round Head Pogo Pin: Reduces wear in frequent use.

- By Application Environment:

- Ordinary pogo pin: For general use.

- High Waterproof Pogo Pin: For wet conditions.

- High-Temperature Resistant Pogo Pin: For extreme heat.

- By Current Transmission:

- Small Current pogo pin: For signal transmission.

- High Current Pogo Pin: For power connections, a key product for a magnetic pogo pin supplier.

- By Installation:

- Surface Mount (SMT) Pogo Pins: For automated PCB assembly.

- Plug-in (THT) Pogo Pins: For manual or semi-automatic assembly.

- By Special Feature:

- Magnetic pogo pin: Uses magnets for easy connection, a specialty for a magnetic pogo pin connector manufacturer.

- Self-Cleaning Pogo Pin: Designed to maintain clean contact surfaces.

- By Customization:

- Customized Length/Shape Pogo Pin: Tailored to specific design requirements.

This diverse range of pogo pin types ensures that designers can find a solution for almost any electronic connection requirement, from standard uses to highly specialized applications.

Key Specifications for Your Pogo Pin Connectors

Beyond type, specific performance metrics are vital. When choosing pogo pin connectors, these details matter greatly for optimal performance.

| Specification | Description | Importance for Buyers like Paul (Automotive) |

|---|---|---|

| Current Rating | Maximum current the pin can safely handle. | Crucial (e.g., up to 15A for ECUs) |

| Durability | Number of mating cycles the pin can endure. | Very High (e.g., 100,000 cycles) |

| Contact Resistance | Electrical resistance at the contact point. | Low resistance is critical for efficiency |

| Spring Force | Force exerted by the spring for a stable connection. | Must be optimized for application |

| Materials | Type of metals and plastics used. | High quality (e.g., imported) for reliability |

| Dimensions | Physical size and shape for integration. | Precision is key for fit |

Using high-quality materials ensures these connectors meet stringent demands.

For instance, an automotive electronics client would prioritize high current ratings and extreme durability.

What Key Factors Should You Consider When Choosing a Pogo Pin Manufacturer?

Feeling lost in the sea of pogo pin manufacturers?

A wrong choice can be a costly setback.

Let’s pinpoint what truly matters for a strong partnership.

When selecting a pogo pin manufacturer, prioritize their quality systems, ability to customize, and production capabilities.

Assess their after-sales service and overall value.

Thoroughly vetting these aspects ensures a reliable partnership for your specific needs.

To make an informed decision, understanding key factors is essential.

This includes focusing on a pogo pin manufacturer’s commitment to quality, their capacity for tailored solutions, and efficient production.

Evaluating these areas carefully will guide your selection process.

Importance of Quality and Certifications for Pogo Pin Suppliers

Quality isn’t just a buzzword, it’s the foundation of a reliable product.

For any Reliable pogo pin manufacturer, certifications are non-negotiable proof of their commitment.

- Key Management & Quality Systems:

- ISO9001: Standard for quality management systems.

- ATF16949: Essential for automotive industry suppliers.

- ISO14001: Environmental management.

- ISO45001: Occupational health and safety.

- 7S Management: Workplace organization methodology.

- Product Compliance:

- CE, TUV: European conformity marks.

- RoHS 2.0, REACH: Restriction of hazardous substances.

- Halogen-Free, California Proposition 65, POPs: Environmental and safety standards.

Manufacturers often highlight their certifications, such as ISO9001 for quality management and industry-specific standards like ATF16949 for automotive suppliers, as these demonstrate their adherence to global benchmarks and rigorous inspection processes.

They ensure every pogo pin and magnetic pogo pin connector meets international standards.

Significance of Customization Capabilities from Your Pogo Pin Manufacturer

Standard components rarely meet every design specification.

This is where expertise in custom pogo pin connectors becomes invaluable.

The ability to provide OEM, ODM, and fully tailored services offers a significant advantage.

Specialized facilities and comprehensive processes—from initial concept to final testing—enable the creation of bespoke solutions.

The custom development process is clear and systematic:

| Step | Description |

|---|---|

| 1. Idea Submission | Customers share their product requirements and initial concepts. |

| 2. Requirement Detail | All technical and design specifics are thoroughly reviewed and clarified. |

| 3. Solution Proposal | Tailored solutions are presented based on detailed requirements. |

| 4. Quotation & Confirmation | Once the proposed solution is confirmed, a quotation is provided. |

| 5. Sample Production | A deposit initiates the production of samples for approval. |

| 6. Sample Approval | The customer evaluates and approves the sample. |

| 7. Bulk Production Deposit | A 30% advance deposit is made for the commencement of bulk manufacturing. |

| 8. Final Payment & Delivery | The remaining payment is made before the delivery of the completed order. |

This systematic approach allows for meeting diverse needs, whether for consumer electronics or intricate automotive systems.

Relevance of Production Capacity and Delivery Times from Pogo Pin Connector Manufacturers

Even innovative designs require efficient production.

Spring loaded pin Manufacturers need to understand the critical role of capacity and speed.

Large facilities, significant workforces, and automated processes enable handling substantial orders efficiently.

This operational model typically allows for:

- Sample Delivery: Typically 15 days.

- Bulk Delivery: Generally between 15 to 20 days.

Such a swift turnaround is highly valued by partners, especially those in dynamic industries like consumer electronics and automotive.

A forward-thinking pogo pin connector manufacturer must indeed prioritize keeping pace with these demands.

Importance of After-Sales Service and Support from Your Spring Loaded Pin Supplier

The relationship with a supplier extends far beyond the point of delivery.

A reliable spring-loaded pin supplier understands the importance of providing continuous support.

This commitment to client satisfaction ensures a seamless experience, from the initial prototype phase through to final delivery and ongoing operation.

This comprehensive support proves invaluable, particularly when dealing with complex projects.

Should any issues arise, or if further assistance or modifications are required, accessible and timely help ensures that operations can continue smoothly.

Balancing Cost and Value with a Pogo Pin Supplier

While cost is always a consideration, the lowest price doesn’t always equate to the best value.

When selecting a pogo pin supplier, it’s beneficial to consider the total cost of ownership.

This encompasses several key factors:

- Material Quality: Using imported, high-grade materials might cost more upfront but prevents failures later.

- R&D Investment: A supplier investing in R&D offers innovative solutions that can save you design and integration costs.

- Reliability and Durability: High-quality pogo pins reduce replacement and maintenance expenses.

- Support and Expertise: The guidance from a Solutions-oriented magnetic pogo pin manufacturer can prevent costly design errors.

Ultimately, the goal is to find a balance between quality, innovation, and service, ensuring durable and reliable magnetic pogo pin solutions that offer true value.

How Can You Effectively Research and Evaluate Pogo Pin Manufacturers?

Knowing where to look is the first step.

The wrong research path can lead to frustration.

Let me share how to efficiently find and assess potential pogo pin suppliers.

To effectively research and evaluate pogo pin manufacturers, prioritize those with robust quality control, transparent material sourcing, and proven industry experience.

Assess their manufacturing capabilities, certifications, and customer support.

Verifying claims through independent reviews and technical specifications is also crucial.

With this foundation, let’s explore practical strategies for identifying suitable partners.

A thorough online investigation is often the best starting point for this process.

Effective Online Research for Pogo Pin Connector Suppliers

The internet is your first and most powerful tool.

- Search Engines: Utilize precise keywords such as "pogo pin manufacturer China," "magnetic pogo pin supplier," or "spring-loaded pin connector."

- Manufacturer Websites: Explore company websites to understand their background, capabilities, and values.

- Product and Solution Pages: Examine detailed product specifications and examples of their applications.

- Blogs and Resources: Review articles and blogs for insights into a manufacturer’s expertise and industry knowledge.

This initial online sweep helps create a shortlist of potential pogo pin connector suppliers.

Utilizing Industry Directories and Trade Shows to Find Magnetic Pogo Pin Suppliers

Beyond online searches, traditional methods are still valuable.

- Industry Directories: Online B2B platforms and specialized directories list magnetic pogo pin suppliers and pogo pin connector suppliers, often with filters for certifications or regions.

- Trade Shows: Events focused on electronics, automotive (like IAA Mobility), medical devices, or industrial automation are excellent for meeting manufacturers.

Face-to-face interaction allows you to assess their products and team directly.

Many manufacturers of pogo pins often participate in such events to connect with potential buyers.- Consumer electronics shows (e.g., CES)

- Automotive technology expos

- Medical device conferences (e.g., MEDICA)

- Industrial automation fairs

These venues offer a chance to see products firsthand and discuss your needs with a potential Foremost pogo pin supplier.

Steps to Verify Manufacturer Reliability for Spring Loaded Pins

Once you have a shortlist, verification is key.

For any Reliable spring loaded pin manufacturer or Trusted pogo pin supplier:

- Request Samples: This is crucial. Test them in your application.

We pride ourselves on our ability to deliver samples quickly. - Verify Certifications: Ask for copies of ISO, RoHS, REACH, etc.

Don’t just take their word for it. - Check References/Case Studies: Look for testimonials or ask about their experience with companies in your industry.

Our partnerships with brands like Samsung, Huawei, and BYD speak to our reliability. - Assess Communication: How responsive and professional are they?

Clear and timely communication is vital. You can test this via their Contact Us page. - Facility Audit (if possible): For large contracts, consider a visit or a third-party audit of the pogo pin manufacturer’s facilities.

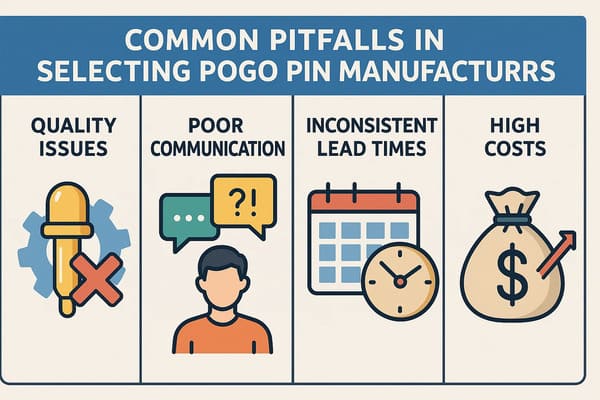

Common Mistakes to Avoid in Selecting a Pogo Pin Manufacturer

Choosing a pogo pin manufacturer can be tricky.

Here are some common pitfalls to sidestep:

- Focusing Solely on Price: The cheapest option often means compromised quality, leading to higher long-term costs.

- Not Verifying Certifications: Assuming a supplier has the claimed certifications without checking can lead to compliance issues.

- Ignoring Communication Red Flags: Slow responses or unclear answers during the initial stages can indicate problems later.

- Skipping Sample Testing: Not thoroughly testing samples from a pogo pin manufacturer in your specific application is a major risk.

- Overlooking Lead Times and Production Capacity: Failing to confirm if a pogo pin connector manufacturer can meet your volume and timeline needs.

- Underestimating Customization Needs: Opting for an off-the-shelf solution when a custom spring-loaded pin connector is truly required might not meet your project’s specific demands.

Avoiding these mistakes will help you find a Specialized pogo pin supplier that is a true partner.

Conclusion

Finding a reliable pogo pin manufacturer like CPT takes effort.

But by focusing on quality, customization, proven capacity, and good communication, you can secure a valuable, long-term partner for your projects.