Ever faced inconsistent test results that derail your production timeline?

Imagine signal loss or slow setups costing time and money.

Pogo pin connectors offer precision and speed to transform your testing process.

Pogo pin connectors enhance test equipment accuracy and efficiency by providing stable, low-resistance connections.

Their spring-loaded design ensures consistent contact force, minimizing signal degradation and intermittent failures.

This reliability allows for faster test cycles and reduces retesting, ultimately improving overall measurement precision and operational throughput.

Keep reading to explore how the pogo pin market can elevate your testing game.

We’ll break down practical benefits and real-world impacts for your business.

What Is the Critical Role of Pogo Pin Connectors in Test Equipment?

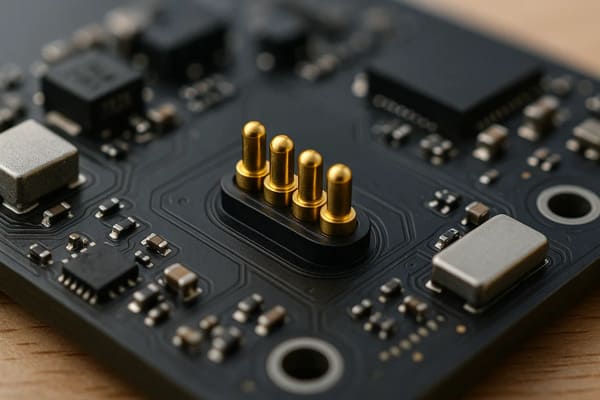

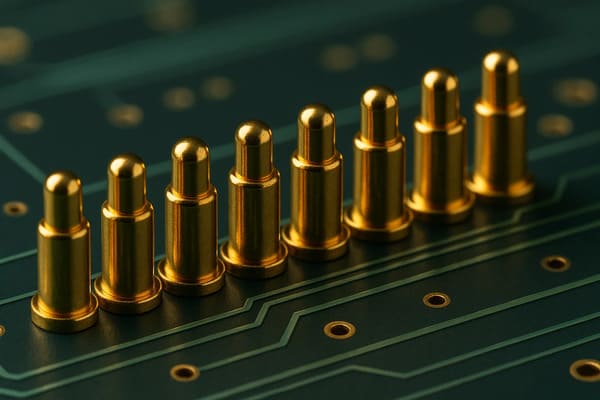

Pogo pin connectors are essential in test equipment, ensuring reliable and precise electrical connections.

Their spring-loaded design maintains consistent contact, which minimizes signal interference and stabilizes measurements.

This prevents errors, reduces retesting needs, and boosts overall test efficiency for accurate results.

Pogo pin connectors are crucial in test equipment because they provide reliable, precise electrical connections.

Their spring-loaded mechanism ensures consistent contact, minimizing signal interference and maintaining stability.

This prevents errors, reduces the need for retests, and enhances overall test efficiency, all vital for accurate electronics testing.

Let’s dig deeper into why connector choice matters.

Stay with us to uncover how advanced pogo pin technology offers a game-changing alternative for your testing needs.

The Escalating Demands for Precision and Speed

Today’s electronics industry pushes for faster, more precise testing as devices grow complex.

High-density circuit boards and miniaturized components require connectors that match these rigorous standards.

A premier pogo pin factory focuses on delivering solutions that keep pace with these evolving needs.

- Rising Complexity: Test equipment needs to manage complex designs without compromising speed or accuracy.

Outdated connectors often struggle with these intricate requirements, leading to performance bottlenecks. - Time Pressure: Achieving quick testing cycles is crucial for meeting strict market deadlines.

This is especially true in sectors like consumer electronics and IoT, where rapid product launches are common. - Zero Error Tolerance: Small signal disruptions can result in incorrect test outcomes. Such errors jeopardize product quality and can damage the credibility of a brand.

This urgency for precision drives the need for cutting-edge spring loaded pin connectors.

We’ve seen how the right design can cut error rates significantly.

Let’s break down how this tech ensures test data you can rely on.

How Connector Quality Impacts Test Integrity

Poor connector performance can lead to signal loss or electrical noise, which often skews test results.

Many options degrade quickly with frequent use, increasing downtime.

Therefore, prioritizing durability and stable contact in test equipment is essential for maintaining integrity.

- Signal Interference: Connections that lack stability can introduce noise.

This distorts critical measurements, especially in sensitive applications such as medical devices. - Wear and Downtime: Connectors lacking robustness often fail under repeated use.

This necessitates pauses for repairs or replacements during crucial testing phases. - Cost Implications: Inaccurate data resulting from subpar connections can lead to faulty product releases.

Such issues directly impact financial performance and consumer trust.

Focusing on superior materials and design in connectors prevents these pitfalls.

The following sections will show how innovative spring loaded pin solutions address these issues effectively.

Pogo Pin Connectors as a Superior Alternative

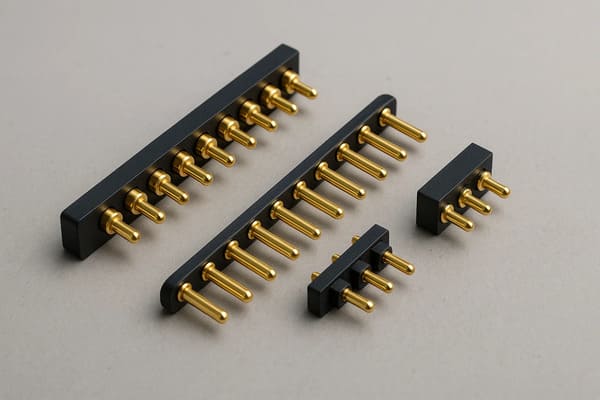

Unlike traditional connectors, pogo pin designs offer self-aligning, spring-loaded contacts for consistent performance.

Their capacity to withstand thousands of cycles without degradation makes them well-suited for high-volume testing applications.

They are designed to meet the demands of rigorous test environments.

- Durability: These spring loaded connectors are engineered to endure millions of connections.

This significantly lessens the need for frequent replacements in demanding test environments. - Ease of Use: Their quick mating capability helps reduce setup time.

This is a crucial benefit for maintaining an efficient workflow within automated test systems. - Custom Options: Pogo pin connectors can be configured in various ways.

This allows them to precisely match specific equipment needs and support diverse project requirements.

These advantages position spring loaded pin connectors as the go-to choice for modern testing.

Let’s explore specific ways they enhance accuracy in the next section.

Enhancing Test Equipment Accuracy with Pogo Pin Connectors?

Are test failures haunting your production line?

Inaccurate results can stem from unstable connections, wasting resources, and time.

Pogo pin connectors offer a fix with reliable, low-resistance contact for precise measurements.

Spring-loaded pin connectors enhance test equipment accuracy by providing stable, low-resistance connections.

Their design minimizes signal loss and reduces electrical noise, which are critical for consistent and precise data acquisition.

This helps ensure reliable measurements and avoids inaccuracies in high-stakes testing environments.

Let’s peel back the layers.

Explore specific ways these connectors sharpen your test equipment’s accuracy below.

Stable and Low-Resistance Connections

Testing demands connections you can trust.

Pogo pin connectors deliver with consistent contact force that curbs signal loss.

This stability is vital for accurate readings, especially in sensitive electronics.

- Uniform Pressure: The spring mechanism applies steady force, ensuring solid electrical contact across cycles.

This cuts down on erratic readings that plague traditional connectors. - Noise Reduction: Electrical noise drops significantly with low-resistance pogo pins.

Variations in impedance are minimized, so your data stays clean and reliable. - Signal Integrity: These spring pins maintain a clear path for signals, avoiding disruptions that skew results.

It’s a must for high-precision tasks.

This focus on stable contact transforms testing outcomes.

Keep exploring to see how it builds a foundation for flawless accuracy.

Minimized Signal Degradation

Signal degradation can ruin test results fast.

Pogo pin connectors combat this with smart material choices.

Gold plating enhances conductivity, while protective designs shield against oxidation and contamination.

- Gold Plating Benefits: This coating ensures optimal signal flow with low resistance.

It fights wear, keeping connections sharp over time. - Anti-Oxidation Measures: Built to resist corrosion, these pins stay effective even in tough conditions.

Contamination risks drop, preserving data quality. - Long-Term Reliability: Consistent performance means fewer signal issues.

Your tests reflect true device behavior without interference.

Signal clarity is non-negotiable in testing.

Let’s look at how alignment plays into this precision next.

Precision Alignment and Repeatability

Misalignment can instantly compromise measurement accuracy.

Pogo pin connectors address this challenge with self-aligning features that ensure exact mating.

They are designed for consistent contact points through countless operational cycles, ensuring reliable and repeatable performance.

- Self-Alignment Design: These pogo pins automatically adjust for minor misalignments, ensuring precise connections consistently.

This eliminates the need for manual adjustments during setup. - Cycle Consistency: Consistent performance is maintained even after thousands of uses.

This significantly reduces measurement variance, leading to greater confidence in test results. - Error Reduction: Stable and reliable mating helps to minimize potential human error during testing procedures.

This ensures your collected data remains dependable across all batches.

Alignment isn’t just a feature; it’s a necessity.

See how it ties into protecting your equipment next.

Mitigation of Wear and Tear on Test Boards

Harsh connectors can damage delicate test boards over time.

Pogo pin connectors provide gentle contact force, unlike friction-heavy alternatives.

This design helps to safeguard devices under test (DUTs), contributing to their overall longevity and reliability during repeated use.

- Soft Engagement: Gentle pressure helps preserve the pads and traces on devices under test.

This significantly reduces the risk of damage compared to more rigid connector types. - Longevity Focus: Reduced wear and tear means test boards can last considerably longer.

This helps save on replacement costs and ensures more consistent operational uptime. - Cost Efficiency: Minimizing damage directly leads to lower repair expenses.

This allows you to focus resources on testing, rather than on unexpected equipment maintenance.

Protecting your gear is crucial for sustained accuracy.

These benefits reshape how you approach testing challenges.

Boosting Test Equipment Efficiency with Pogo Pin Connectors?

Struggling with slow test cycles that bottleneck production?

Efficiency in testing saves hours and resources, yet traditional connectors drag you down.

Pogo pin connectors speed up processes with quick mating and high durability.

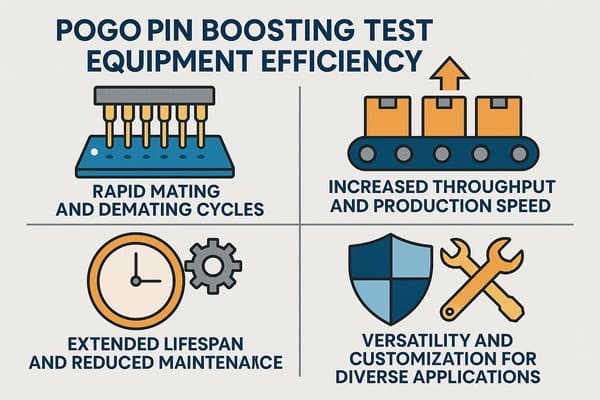

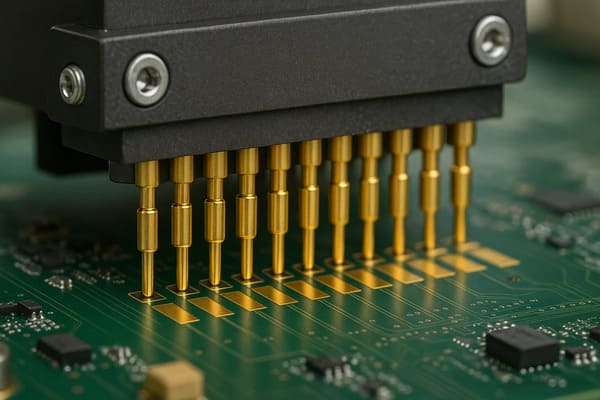

Pogo pin connectors enhance test equipment efficiency by enabling rapid connect and disconnect cycles, which significantly reduces setup times.

Their design facilitates increased throughput and makes them ideal for high-volume testing environments.

This optimization of workflow contributes to substantial savings in both time and resources during production.

Stick with us to unpack efficiency gains.

We’ll detail how pogo pins cut delays and elevate performance.

Rapid Mating and Demating Cycles

Efficiency is paramount in testing scenarios.

Spring-loaded pin connectors allow for swift connections, making them ideal for high-volume setups where minimizing downtime is critical.

They significantly accelerate the testing process.

- Quick Connects: These pogo pin connectors snap into place effortlessly, eliminating the need for fiddly alignment.

This design noticeably shrinks both setup and teardown times. - Cycle Speed: Fast mating capabilities support rapid testing loops, allowing more units to be handled in less time.

This process occurs without common interruptions. - Ease of Use: Simplified engagement mechanisms mean less extensive training for staff.

This streamlined approach directly contributes to increased efficiency with minimal effort.

Speed reshapes your output potential.

Let’s explore how it fuels broader production gains.

Increased Throughput and Production Speed

Inefficient testing can bottleneck an entire production line.

Pogo pin connectors help streamline processes, enabling faster product delivery.

Their design allows them to integrate smoothly with automated systems.

- Workflow Gains: Streamlined testing cycles directly translate to more tests completed per hour.

This ensures that production can maintain a consistent pace with demand. - Automation Fit: These pins are well-suited for robotic systems, helping to reduce human-induced delays.

Automated lines can thus operate more smoothly and quickly. - Market Edge: Faster testing capabilities ultimately shorten the time it takes for products to reach the market.

This allows businesses to release their offerings ahead of competitors

Throughput isn’t just a number; it’s your competitive advantage.

Next, see how pogo pin durability supports this speed.

Extended Lifespan and Reduced Maintenance

Frequent connector replacements can deplete resources.

Pogo pin connectors are designed to endure high cycle counts, which helps to significantly ease maintenance burdens.

Their robust construction supports long-term operational efficiency.

- High Cycle Life: Engineered for tens of thousands of uses, these connectors typically outlast many traditional alternatives.

This extended lifespan leads to fewer replacements, saving valuable time. - Low Maintenance: Their longevity reduces the need for frequent repair stops.

This allows operational focus to remain on testing rather than on equipment upkeep. - Cost Savings: Durable designs result in less expenditure on spare parts.

This reliability ensures that budgets can be allocated more effectively, maximizing the utility of existing equipment.

Longevity drives efficiency forward.

Let’s look at how customization adds another layer of value.

Versatility and Customization for Diverse Applications

A universal solution rarely suits all testing environments.

Pogo pin connectors offer a wide range of tip styles and configurations to accommodate various surfaces.

They can be adapted for unique test requirements.

- Tip Variety: A selection of tips, including pointed, flat, or cupped options, allows for precise contact.

This ensures a perfect match for diverse application needs. - Custom Designs: These spring loaded connectors can be adapted to highly specific requirements, with tailored sizes or spring forces.

This offers effective solutions for nearly any test scenario. - Broad Use: From [consumer electronics](Top Trends in Consumer Electronics Industry "consumer electronics") to heavy-duty industrial equipment, these components are suitable for diverse applications.

Their inherent flexibility significantly enhances overall utility.

Versatility ensures no test is out of reach.

These options make pogo pins indispensable for efficiency.

Real-World Applications and Case Studies of Pogo Pin Connectors?

Wondering about the practical performance of spring-loaded pin connectors?

Their real-world applications demonstrate their positive impact on testing accuracy and speed.

Examples from various industries highlight their proven value.

Spring-loaded pin connectors are widely used across various industries for their reliability in testing.

In consumer electronics, they enable precise diagnostics for smartphones and wearables.

The automotive sector employs them for electric vehicle testing, where they withstand harsh vibrations.

They also prove essential in aerospace and medical device applications, ensuring signal integrity under challenging conditions.

Let’s dive into these stories.

Discover how they solve real challenges in your field below.

Consumer Electronics Testing

Smartphones need flawless testing for market readiness.

Pogo pin connectors deliver spot-on connections for signal checks, catching flaws early.

One project saw test cycles drop by 25% with their quick mating feature.

- Precision Data: Stable contacts help detect even small signal issues.

This ensures high product quality before release. - Speed Gains: Quick setups accommodate large production volumes.

This helps meet demanding manufacturing schedules. - Reliability: Their durability provides consistent results over many test cycles.

This prevents connector failures during critical testing.

Beyond consumer devices, spring-loaded pin connectors are crucial in demanding environments.

They ensure critical connections in the automotive and aerospace industries.

Automotive and Aerospace Testing

Electric vehicles and aircraft demand rugged testing tools.

Pogo pin connectors resist vibrations, ensuring accurate diagnostics.

A German automotive firm boosted efficiency by 30% using custom designs for harsh settings.

- Tough Conditions: These pogo pin connectors offer strong vibration resistance, ensuring stable and consistent readings.

This allows for highly reliable data collection even during the most rigorous testing environments. - Fast Cycles: Their quick connection capabilities significantly accelerate diagnostic processes.

This efficiency enables the testing of a greater number of vehicles accurately, thereby improving daily output. - Custom Fit: The ability to tailor these connectors to unique interfaces is a key advantage.

This ensures testing systems can seamlessly adapt to even the most complex and specialized design requirements.

The reliability and adaptability of these connectors are not limited to vehicles and aircraft.

They are equally vital in other sectors where precision is paramount, such as medical device development.

Medical Device Testing

Medical gear can’t afford errors in testing.

Pogo pin connectors provide interference-free signals for diagnostics.

An emergency device maker reported zero signal loss during critical validation phases.

- Signal Clarity: The anti-interference design of these connectors ensures precise and accurate readings.

This critical feature helps maintain the highest standards for patient safety and diagnostic reliability. - Stable Use: With their extended cycle life, these connectors reliably support repeated testing protocols.

This consistency is crucial for maintaining equipment reliability throughout numerous validation cycles. - Harsh Settings: Some designs offer waterproof options, enabling reliable performance in humid or challenging conditions.

This durability ensures consistent functionality even in demanding medical environments.

These cases highlight tangible benefits.

See how choosing the right connector builds on these successes next.

Choosing the Right Pogo Pin Connector for Your Needs?

Overwhelmed by connector options for your test setup?

Picking the right pogo pin connector can significantly impact performance.

Understanding key specifications and application demands is crucial for optimal results.

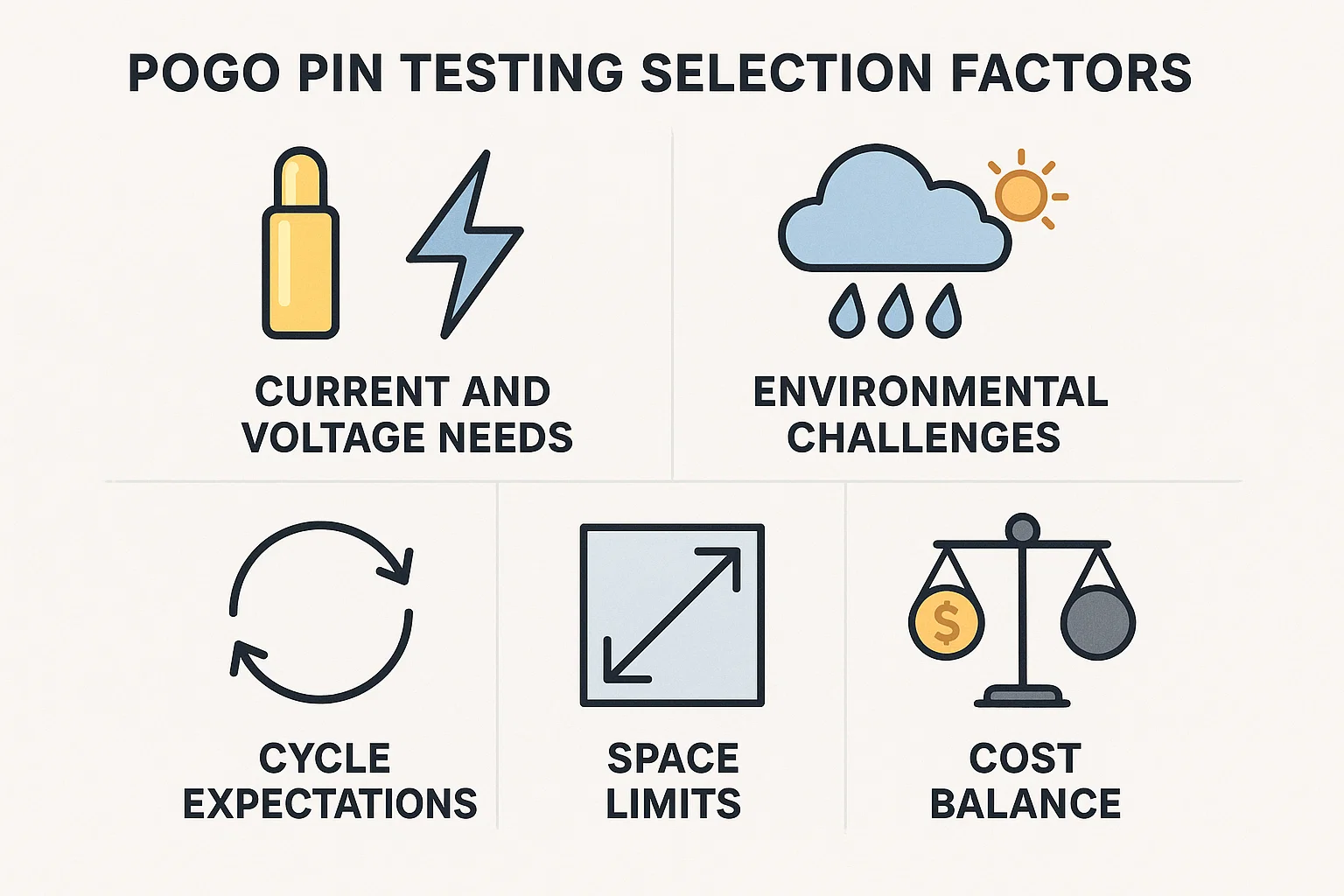

Selecting the right spring-loaded pin connector involves evaluating several factors, including current ratings, voltage needs, and environmental conditions.

It’s essential to consider cycle life, space limitations, and cost-effectiveness.

Aligning these technical specifications with your application’s demands ensures optimal performance and seamless integration.

Let’s break it down further.

We’ll walk through key considerations and collaboration benefits next.

Factors to Consider

Matching a pogo pin connector to your test needs takes careful thought.

Each spec impacts accuracy and efficiency differently.

Based on industry expertise, here are critical points to weigh.

- Current and Voltage Needs: Ensure the pins can safely handle your required power levels without overheating.

Specialized options are available for high-current or high-voltage applications, supporting demanding setups. - Environmental Challenges: Performance can be affected by factors like Temperature, vibration, or humidity.

Choose pogo pin connectors specifically rated to withstand the particular conditions of your operational environment. - Cycle Expectations: The rated lifespan of a connector should align with your expected usage frequency.

High-cycle pins are ideal for applications requiring frequent testing, minimizing wear over time. - Space Limits: Consider compact designs if your setup has restricted space.

Always verify dimensions to ensure smooth and efficient integration into your existing test rigs. - Cost Balance: Evaluate the initial purchase price against the long-term value.

Investing in durable pins can lead to lower total ownership costs due to reduced maintenance and replacement needs.

These factors shape a smart choice.

Next, see why expert input refines this process.

Importance of Consulting with Manufacturers

Guessing on specs risks mismatched gear.

Partnering with a state-of-the-art pogo pin supplier brings clarity.

Experience shows that direct dialogue with manufacturers uncovers ideal solutions for test setups.

- Tailored Advice: Consulting with experts helps assess your unique needs, leading to precise recommendations.

This approach can help avoid costly trial-and-error in your selection process. - Custom Options: Specialized services can provide connectors designed for specific test rigs.

This ensures you receive components that are perfectly suited for your particular application. - Technical Support: Ongoing guidance from professionals ensures successful integration of the connectors.

Access to expert insights helps in resolving any challenges that may arise during implementation.

Collaboration turns selection into strategy.

It’s the final step to lock in testing excellence.

Conclusion

Pogo pin connectors redefine test equipment accuracy and efficiency with stable connections, rapid cycles, and custom designs.

These benefits empower your business to achieve reliable results and faster production.

For cutting-edge solutions in the pogo pin market, explore our homepage or reach out via our contact page.

We’re ready to support your testing needs with precision and expertise.