Have you ever faced a mission-critical failure due to a tiny connector?

It’s a nightmare in the aerospace and defense industries.

One weak pogo pin can jeopardize entire systems.

Let’s explore why they’re essential.

Pogo pins are the go-to choice for aerospace and defense due to their unmatched reliability in high-stakes environments.

These connectors are engineered to withstand extreme conditions, including shock, vibration, and temperature fluctuations.

Their stable performance helps prevent catastrophic failures, ensuring consistent and dependable operation in critical systems where precision is paramount.

Stick with us for deeper insights.

Discover how pogo pins meet the toughest demands.

We’ll guide you through their critical role in defense and aviation.

How Do Pogo Pins Meet the Demands of Extreme Environments?

Harsh conditions test every component in aerospace projects.

Extreme temperatures or vibrations can break standard connectors.

Pogo pin designs stand out in these unforgiving settings.

Pogo pins meet the demands of extreme environments through their robust construction.

They are designed to resist corrosion, withstand significant shock, and maintain stable electrical contact under continuous pressure and vibration.

This durability ensures consistent performance and operational integrity even in the most challenging industrial and environmental conditions.

Let’s dig into specifics.

These details will reshape how you view connector selection.

Stay tuned for practical tips on extreme performance.

Durability and Resistance in Harsh Conditions

Tough environments demand unbreakable components for mission success.

Selecting connectors that withstand stress is non-negotiable for defense applications.

- Withstanding extreme temperatures and pressure: Pogo pins perform in ranges from -55°C to 200°C.

High-pressure scenarios, like in deep-space tech, don’t faze them.

This ensures functionality in critical missions. - Resisting vibration and mechanical shock: Aerospace gear faces constant turbulence or impact.

Pins rated for 50g shock and 10g vibration stay secure.

They keep systems running during high-stress flights. - Preventing corrosion from moisture, chemicals: Humidity and chemical exposure can degrade contacts.

Sealed designs and resistant platings protect against rust.

This is vital for equipment in coastal or industrial zones. - Ensuring stable connections despite contaminants: Dust and debris often disrupt contact points.

Self-cleaning or sealed spring loaded pins combat this.

They maintain reliability even in gritty battlefield conditions.

These factors ensure uptime in adversity.

Next, let’s see how materials boost this resilience.

High-Performance Materials for Reliability

Material choices can make or break connector performance.

In extreme settings, only premium options survive.

A precision pogo pin factory provides access to top-tier builds.

- Utilizing materials for extreme environments: Beryllium copper offers strength and elasticity under stress.

Stainless steel resists harsh climates.

These bases handle aerospace’s toughest demands with ease. - Selecting platings for corrosion protection: Gold plating fights oxidation even in salty air.

Nickel underlayers add durability against wear.

These coatings extend life in corrosive defense settings. - Special alloys for enhanced conductivity: Certain alloys boost signal clarity despite interference.

They’re ideal for high-frequency data links.

This keeps communication systems sharp during operations. - Customized designs for specific applications: Tailored solutions meet unique OEM needs.

Custom spring loaded pin connectors fit odd specs or tight spaces.

This flexibility addresses niche project challenges.

Material innovation drives dependability.

Let’s explore pogo pins’ role in critical systems next.

What Role Do Pogo Pins Play in Mission-Critical Systems?

Vital systems collapse without flawless connectivity.

In aerospace and defense, failure isn’t an option.

Spring loaded pin designs ensure precision under pressure.

Pogo pins play a crucial role in mission-critical systems by guaranteeing signal integrity and reliable power delivery.

They support essential functions in avionics, secure data transmission, and are designed to resist tampering.

Their precise and consistent connectivity safeguards operational success and system functionality in demanding applications where reliability is paramount.

Keep reading for key details.

These insights reveal why pogo pins dominate critical applications.

Let’s break down their impact.

Precision and Performance in Aerospace

Flawless operation in flight systems starts with tiny connectors.

Aerospace demands pinpoint accuracy for safety.

Robust pogo pin designs deliver every time.

- Ensuring signal integrity in communications: Clear signals are life-or-death in missions.

Low-resistance pins prevent data loss in radios.

They keep channels open during critical operations. - Delivering consistent power to avionics: Cockpit systems need a steady energy flow.

High-current pogo pins handle up to 9 amps.

This powers navigation without dangerous drops. - Enabling data transfer for flight systems: Fast, secure data links guide aircraft.

Spring loaded pins support high-speed transfers.

They ensure real-time updates for pilots. - Maintaining reliability under high G-forces: Extreme maneuvers stress every part.

Pins built for G-force resistance stay connected.

This prevents failures during sharp turns or rapid climbs.

Precision keeps missions on track.

Next, let’s tackle security-focused designs.

Security and Tamper-Proof Designs

Protection against interference is crucial in defense.

Unsecured connections risk data breaches or failure.

Advanced pogo pin solutions lock down vulnerabilities.

- Integrating secure, reliable connections: Pins with tight tolerances prevent signal leaks.

They ensure encrypted systems stay safe.

This is key for classified communications. - Protecting against accidental disconnections: Floating or magnetic designs resist unintended separation.

They hold firm during turbulence.

This avoids disruptions in active zones. - Offering robust, sealed designs: Waterproof and dustproof builds shield internals.

They block environmental threats to sensitive gear.

Ideal for rugged field deployments. - Customizing connectors for proprietary systems: Unique shapes or locking mechanisms deter tampering.

Tailored spring loaded pin connectors fit exclusive setups.

This adds a layer of defense.

Security enhances trust in systems.

Up next, let’s see how these pins streamline workflows.

How Do Pogo Pins Streamline Manufacturing and Maintenance?

Production delays or maintenance hiccups cost time and money.

In defense sectors, efficiency matters as much as performance.

Pogo pin technology simplifies the design and assembly of both.

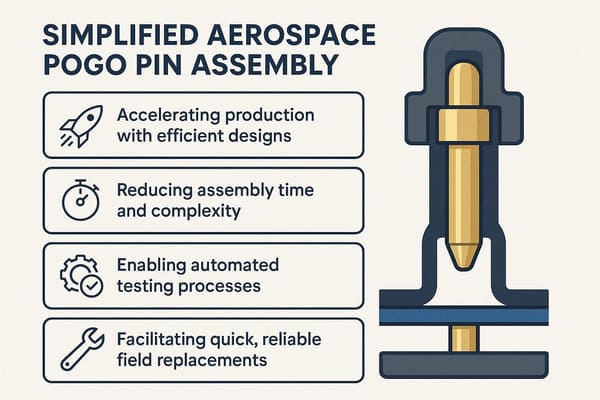

Pogo pins streamline manufacturing and maintenance by significantly cutting assembly time and simplifying repairs.

They facilitate automated testing processes and contribute to reduced long-term operational costs.

Their design flexibility also allows for efficient integration into various B2B applications, enhancing overall production efficiency without compromising product integrity.

Dive deeper with us.

These tips will optimize your supply chain.

Let’s uncover practical benefits for operations.

Simplified Assembly and Testing

Complexity slows down production lines unnecessarily.

Streamlined connectors save hours in aerospace assembly.

Efficient designs from a premier spring loaded pin wholesaler make the difference.

- Accelerating production with efficient designs: Surface-mount pins fit automated lines perfectly.

They snap into place without manual tweaks.

This speeds up high-volume manufacturing. - Reducing assembly time and complexity: Pre-aligned or floating pins simplify integration.

They adjust to slight mismatches naturally.

This cuts errors in tight defense deadlines. - Enabling automated testing processes: Spring probes support fast test rigs for quality checks.

Their consistent contact ensures accurate readings.

This boosts throughput in validation stages. - Facilitating quick, reliable field replacements: Swappable designs allow rapid fixes on-site.

No special tools are needed for swaps.

This keeps equipment operational during missions.

Ease of use transforms workflows.

Let’s look at cost and lifespan benefits next.

Long-Term Cost-Effectiveness and Lifespan

Budget overruns plague defense projects without smart planning.

Durable connectors curb expenses over time.

A solutions-oriented pogo pin supplier prioritizes lasting value.

- Minimizing maintenance with durable components: High-cycle pins, rated over 100,000 uses, rarely fail.

They resist wear in harsh conditions.

This slashes repair frequency significantly. - Reducing the total cost of ownership: Quality materials avoid frequent replacements.

Initial costs pay off with reliability.

This balances budgets in long-term contracts. - Extending product life cycles: Robust spring probes outlast weaker alternatives.

They handle stress without degrading.

This delays full system overhauls for years. - Ensuring interoperability for future upgrades: Standard or custom designs adapt to new tech.

They fit evolving aerospace needs.

This prevents obsolescence in dynamic fields.

Smart choices save resources.

These factors cement pogo pins as indispensable.

Conclusion and Call to Action

Pogo pins are vital for aerospace and defense, offering durability, precision, and efficiency.

They ensure reliability in extreme conditions and streamline operations.

Explore our customized pogo pin solutions on CTP’s homepage or get in touch with our experts via Contact Us.

We’re ready to support your B2B mission-critical needs.