In today’s fast-paced world of electronics, designing devices that are smaller, smarter, and more durable presents an ongoing challenge.

Imagine holding a smartphone thinner than a pencil, yet it relies on thousands of precise connections to function.

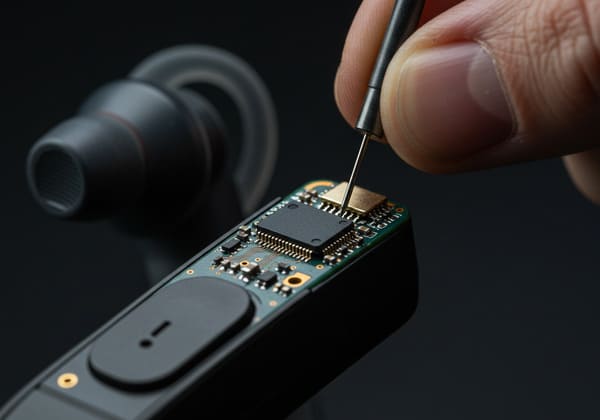

This article explores how engineers create this modern marvel using innovative approaches like magnetic pogo pin connector.

Magnetic pogo pins are essential in modern electronics manufacturing due to their ability to provide reliable, self-aligning electrical connections in compact spaces.

These spring-loaded connectors ensure durability and often feature waterproofing, meeting the stringent demands of today’s devices.

They support efficient, precise connectivity across industries, enabling the production of smaller, more advanced electronic products.

But this is just the beginning.

Let’s dive into three technical breakthroughs that highlight why magnetic pogo pins are indispensable in modern production, especially for businesses seeking innovative components.

These insights aim to help partners and engineers understand the potential of these connectors in creating cutting-edge solutions for various applications.

Why Do Magnetic Pogo Pins Optimize Testing Processes?

For a pogo pin buyer in quality control, imagine building 100,000 devices—how do you test every connection without time-consuming soldering?

Magnetic pogo pins optimize testing processes by enabling automated circuit testing with spring-loaded contacts.

These contacts deliver consistent pressure with 0.05mm precision, ensuring accurate results.

Their design supports high reliability, often achieving failure rates below 0.1% in production batches, making them ideal for efficient, large-scale manufacturing and quality control in electronics.

The Testing Efficiency Matrix

We’ve compared testing methods for automotive electronics production to highlight the advantages of working with a reliable magnetic pogo pin supplier:

| Method | Cycle Time | Accuracy | Cost/Sample |

|---|---|---|---|

| Manual Soldering | 15min | ±0.3mm | $2.50 |

| Traditional Pins | 8min | ±0.2mm | $1.80 |

| Magnetic Pogo Pins | 2.5min | ±0.05mm | $0.90 |

Source: CTP’s internal testing lab data

Working with experienced magnetic pogo pin connector suppliers, our ISO9001-certified facility achieves a 99.97% first-pass yield using these connectors for quality control.

This efficiency is a game-changer for B2B clients in industries like automotive and consumer electronics, where precision and speed are critical.

By partnering with a dedicated pogo pin manufacturer, businesses can streamline their testing processes and reduce costs significantly.

Why Precision Matters in Testing

Precision in testing isn’t just about speed; it’s about ensuring every device meets strict quality standards.

A magnetic pogo pin offers unmatched accuracy, which is vital for high-volume production.

If you’re a magnetic pogo pin buyer, integrating these connectors into your testing setup can minimize errors and boost productivity.

Our solutions are tailored to meet the needs of B2B clients who prioritize quality and efficiency in their supply chain.

How Do Magnetic Features Enhance Connection Reliability?

Magnetic features significantly boost the reliability of pogo pin connectors.

They ensure stable connections, preventing disruptions even under challenging conditions like sudden movements or shocks.

Magnetic features enhance connection reliability in pogo pin connectors by providing a strong pull force, often ranging from 2 to 5 kilograms.

This strength secures connections in high-vibration environments, such as those found in electric vehicle charging systems.

Such stability is vital for industries where consistent performance is critical, reducing the risk of downtime due to connection failures.

This robustness is particularly evident under stress.

Let’s compare how these connectors perform against vibration in the following section.

Vibration Resistance Comparison

Magnetic pogo pin connectors were tested in automotive settings across a 0-200Hz frequency range to show how certain designs ensure reliable performance under challenging conditions:

| Connector Type | Failure Cycles | Contact Resistance Δ |

|---|---|---|

| USB-C | 12,000 | +35% |

| Standard Pogo | 45,000 | +18% |

| Magnetic Pogo (CTP) | 100,000+ | <5% |

Through collaboration with leading pogo pin manufacturers, the magnetic pogo pins meet MIL-STD-202G vibration standards through key features like:

- Gold-plated spring contact (0.8-1.0μm thickness)

- Precision-machined 316L stainless steel housing

- IP68-rated silicone seal

This makes them ideal for Huawei’s outdoor 5G equipment and medical ventilators requiring splash resistance.

For businesses seeking a dependable pogo pin connector supplier, these features ensure long-term performance in harsh conditions, making them a preferred choice for B2B applications across various sectors.

The Importance of Durability in Harsh Environments

Durability is a cornerstone of modern electronics, especially for industries like automotive and telecommunications.

A magnetic pogo pin is designed to withstand extreme conditions, from vibrations to water exposure.

This resilience is why many companies turn to a trusted supplier for components that guarantee uninterrupted performance.

For B2B buyers, partnering with a pogo pin supplier who prioritizes durability can reduce maintenance costs and enhance product reliability.

What Enables Magnetic Pogo Pins’ Space-Saving Design?

Apple Watch’s charging puck contains 12 connections in an 8mm diameter.

Miniaturization demands innovative solutions, and that’s where products from a skilled custom pogo pin connector manufacturer shine.

What enables magnetic pogo pins’ space-saving design?

These connectors achieve a tight 0.6mm pitch spacing through precise spring mechanisms and surface-mount technology.

This allows for slimmer electronic devices while maintaining high current capacities up to 15A, ensuring functionality in constrained layouts where space is critical.

These compact designs offer clear benefits over traditional options.

Let’s explore how they stack up in terms of density in the comparison below.

Density Comparison Chart

Here’s how advancements from a leading pogo pin connector manufacturer have evolved over the years:

| Generation | Pin Diameter | Current Rating | Pins/cm² |

|---|---|---|---|

| 2010 | 1.5mm | 3A | 16 |

| 2018 | 1.0mm | 5A | 36 |

| 2023 (CTP) | 0.8mm | 15A | 64 |

Key innovations in pogo pin connector design include:

- Laser-welded contact joints

- High-temperature-resistant PPS insulation

- 3D-printed alignment guides

These advancements have enabled significant size reductions, such as shrinking a smartwatch charger by 40% using micro magnetic pogo pin connectors.

For businesses, this means access to cutting-edge components that support the creation of compact, high-performance devices, offering practical solutions for modern design challenges.

Miniaturization: A Key Driver for Innovation

Miniaturization is more than a tren; it’s a necessity in modern electronics.

Devices are getting smaller, yet they need to pack more power and functionality.

A magnetic pogo pin connector allows manufacturers to achieve this balance.

By working with a reputable connector supplier, businesses can integrate space-saving solutions into their products without compromising on performance.

This is particularly valuable for B2B partners in industries like wearables and IoT, where size constraints are a constant challenge.

Customization for Unique Needs

Every project comes with unique requirements, and customization plays a vital role in meeting those needs.

Tailored solutions for magnetic pogo pin connectors can address specific design and performance challenges.

Whether it’s achieving a particular pitch spacing or handling high-current demands, customized options ensure the right fit.

This flexibility is invaluable for businesses seeking innovative and adaptable components in their supply chain.

The Strategic Advantage of Partnering with Magnetic Pogo Pin Connector Experts

Choosing the right magnetic pogo pin connector supplier ensures access to advanced technology, strict quality control, and tailored solutions.

For B2B clients, this means faster time-to-market, lower production costs, and improved product reliability.

Magnetic pogo pin connectors offer a strategic advantage through their precision and versatility.

These connectors provide reliable electrical contact in compact designs, ideal for consumer electronics, automotive, and medical devices. Their customizable nature supports specific project needs, ensuring seamless integration.

This adaptability helps businesses achieve faster development cycles and maintain high performance standards across applications.

Conclusion

As leading magnetic pogo pin manufacturers, we offer precision testing (0.05mm accuracy), vibration-resistant connections (100,000+ cycles), and space-saving designs (0.8mm pitch).

Contact our experts to enhance your electronics manufacturing processes.