Hey there, are you worried about the durability of connectors in your products?

Let’s talk about the lifespan of a pogo pin and why it matters.

A pogo pin’s lifespan is typically measured in mating cycles, ranging from 10,000 to over 100,000 cycles.

The durability depends on factors like materials, design, and environmental conditions.

High-quality pogo pins, often gold-plated for enhanced conductivity and corrosion resistance, ensure extended operational life and reliable performance.

Now, let’s dive into the details.

Understanding these factors helps in selecting the right pogo pins for your specific application.

Careful consideration ensures optimal performance and longevity.

Defining Pogo Pin Lifespan: What Are Mating Cycles?

To grasp the durability of a pogo pin, it is essential to understand how its lifespan is measured.

The key metric is the ‘mating cycle.’ This concept is fundamental.

A mating cycle is defined as one complete instance of a pogo pin engaging and disengaging with a contact surface.

This single action of connection and disconnection serves as the standard unit for measuring a pogo pin’s mechanical endurance.

The total number of cycles a pin withstands determines its operational lifespan.

With this definition established, let’s examine the practical implications.

Understanding mating cycles is key to selecting components that ensure long-term product reliability.

Understanding Mating Cycles for Pogo Pin Buyers

Mating cycles are a crucial reliability metric in demanding fields like consumer electronics and automotive.

For example, gold-plated contacts help ensure the pins can meet high durability ratings, often exceeding 20,000 cycles.

Consider the example of a wearable tech device.

Its pogo pins must perform reliably through constant use.

The right component selection is critical to its success.

To break this down further:

- Cycle Range: Standard pins start at 10,000 cycles, while premium ones reach 10,0000.

- Testing Standards: We use precision equipment to simulate real-world use.

- Impact on Design: High-cycle pogo pins reduce replacement costs for your products.

Here’s a quick look at cycle ratings for different types of pins:

| Pin Type | Mating Cycles | Best For Industry |

|---|---|---|

| Standard Pogo Pin | 10,000 – 50,000 | General Electronics |

| High-Durability Pin | 100,000 – 1,000,000 | Automotive & Medical |

| Magnetic Pogo Pin | 100,000+ | Wearables & IoT |

This structure helps you pick the right spring loaded pin connector for longevity.

Key Factors That Influence Pogo Pin Lifespan: What Affects Durability?

Connector failure can be a frustrating issue.

It is important to identify what impacts pogo pin lifespan.

This knowledge helps prevent premature wear and ensures reliability.

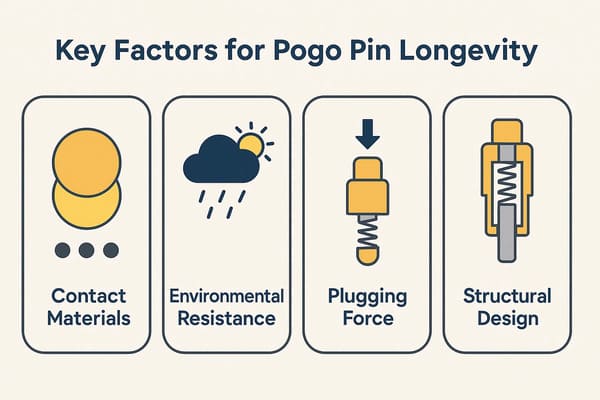

A pogo pin’s durability is determined by key factors spanning its design and application.

These include material selection for the barrel and plunger, manufacturing precision, and plating quality.

Environmental conditions like temperature and humidity, along with the specific plugging force applied, also directly impact its lifespan and reliability.

With these key areas identified, let’s delve deeper.

A closer look is needed to understand these factors.

This will clarify what determines true durability.

Material and Design Choices for Spring Loaded Pin Longevity

Material selection is fundamental to a pogo pin’s durability.

Factors such as gold plating thickness and copper conductivity directly influence its lifespan.

Making the right material choices is crucial to prevent premature failure.

Here’s what matters:

- Contact Materials: Gold over nickel ensures low wear and high conductivity.

- Environmental Resistance: Waterproof or high-temperature pogo pins last longer in harsh settings.

- Plugging Force: Too much or too little force can damage pogo pins over time.

- Structural Design: A well-designed plunger and spring reduce mechanical strain.

Check this table for how materials affect durability:

| Material Feature | Impact on Lifespan | Industry Fit |

|---|---|---|

| Thick Gold Plating | Increases cycles to 100,000+ | Medical & Aerospace |

| Nickel Substrate | Prevents corrosion | Automotive |

| Optimized Spring Design | Reduces wear over time | Consumer Electronics |

Ultimately, a pogo pin’s longevity results from multiple interconnected factors.

Careful attention to both material science and structural design is essential.

These elements together determine its true durability and reliability.

Why Does Pogo Pin Lifespan Matter for Your Products?

Connector failure can significantly impact product performance.

Ensuring component longevity prevents disruptions and maintains user satisfaction.

This directly contributes to a product’s overall success.

A pogo pin’s lifespan is critical because it directly impacts product reliability and customer satisfaction.

Durable pins reduce device failures, ensuring consistent performance over time.

This longevity contributes to fewer warranty claims and a stronger market reputation, reflecting positively on product quality.

There’s more to this story.

Understanding how connector choices influence device performance can significantly enhance product value.

Let’s explore the details.

Product Reliability with Durable Magnetic Pogo Pin Solutions

The lifespan of a spring-loaded pin significantly influences trust in a product.

High mating cycles ensure stable electrical connections, which is crucial for demanding applications like IoT or medical devices.

This directly translates to enhanced product reliability.

Here’s why it matters:

- Consistent Performance: Long lifespan means stable signals over time.

- Reduced Downtime: Fewer replacements save time and money for B2B buyers.

- Customer Trust: Reliable products build loyalty in competitive markets.

- Brand Value: Quality pogo pin connectors enhance your product’s reputation.

Here’s a quick comparison of lifespan impact:

| Lifespan Range | Impact on Product | Market Advantage |

|---|---|---|

| 10,000 Cycles | Basic reliability | Entry-Level Devices |

| 100,000+ Cycles | High reliability | Premium & Industrial Use |

Choosing connectors with an appropriate lifespan is vital for product success.

It ensures consistent performance, minimizes costly downtime, and builds strong customer trust.

Ultimately, this strategic decision enhances a product’s reputation and market value.

Maximizing Pogo Pin Lifespan: How to Choose the Right Pogo Pin and Partner?

connector failures can significantly impact your operational efficiency and budget.

Understanding how to maximize pogo pin lifespan is key to avoiding these frustrations.

To maximize pogo pin lifespan, select connectors made with high-quality materials resistant to wear.

Partnering with a manufacturer offering custom designs and comprehensive testing protocols is also crucial.

This ensures the pins meet specific application demands for durability and performance, minimizing premature failure.

Let’s explore this further.

Focusing on informed decisions for component selection is essential for achieving optimal performance and longevity in your applications.

Selecting a Trusted Spring Loaded Pin Manufacturer

Choosing an effective partner is crucial for sourcing spring-loaded pins.

Prioritize suppliers demonstrating rigorous quality control and efficient sample delivery.

This collaborative approach can significantly enhance project success and product longevity.

Consider these:

- Material Quality: Opt for gold-plated, corrosion-resistant pogo pins.

- Customization Options: Tailor pins to your specific needs for better lifespan.

- Supplier Reliability: A partner with ISO certifications ensures quality.

- Testing Support: Verify cycle ratings with real-world simulations.

Here’s how to evaluate a durable pogo pin supplier:

| Criteria | Why It Matters | CTP Advantage |

|---|---|---|

| Material Standards | Affects durability | Imported, certified |

| Custom Design | Matches application | Full R&D support |

| Delivery Speed | Meets project timelines | Samples in 15 days |

To maximize pogo pin lifespan, focus on material quality, customization, and thorough testing.

Selecting a partner committed to these areas ensures reliable, long-lasting performance.

Prioritize those who offer comprehensive support throughout your project.

Choosing a Trusted Partner for Durable Pogo Pin Solutions

Finding a dependable source for pogo pin connectors can be challenging, but it’s crucial for product success.

This section outlines key considerations for selecting a provider that stands out in this field.

To choose a durable pogo pin solution provider, evaluate their adherence to industry standards like CE and RoHS.

Verify their comprehensive quality control and management practices.

Assess their capability to offer integrated solutions from initial design to final product delivery, ensuring consistent reliability and performance.

Let’s delve into what truly differentiates leading providers.

Their commitment to excellence and a customer-focused approach are often defining characteristics.

Continue reading to discover more insights.

Precision and Innovation from a Reliable Pogo Pin Supplier

For high-quality magnetic pogo pin connectors, prioritize providers with a strong focus on quality.

Evaluate facilities based on their production and testing capabilities, alongside their commitment to research and development.

Look for a history of successful, high-reliability spring loaded pins.

Here’s what to look for in a top-tier supplier:

- Advanced Equipment: High-precision tools are essential for ensuring consistent quality across all products.

- Fast Turnaround: Efficient timelines for both sample delivery (e.g., in 15 days) and bulk production (e.g., in 20 days) are vital for meeting project schedules.

- Global Standards: Adherence to certifications such as ISO9001 and ATF16949 demonstrates a commitment to international quality benchmarks.

- Custom Expertise: The ability to offer tailored designs, from specific pin counts to specialized applications in areas like IoT or automotive, is a significant advantage.

Here’s why many buyers choose providers who offer these state-of-the-art solutions:

| Feature | Benefit | Industry Impact |

|---|---|---|

| 7S Management | Streamlined operations | Consistent Quality |

| R&D Centers | Innovative designs | Tailored Solutions |

| Quick Samples | Faster decision-making | Project Speed |

Ultimately, selecting a pogo pin provider involves assessing their dedication to quality and innovation.

A partner committed to these principles ensures robust, reliable connector solutions for diverse applications.

Conclusion

In short, pogo pin lifespan matters for product success.

At CTP, we deliver durable, high-quality solutions.

Contact us today to boost your reliability!