Choosing the right connector can be puzzling.

Make the wrong choice, and your device might not perform as expected.

Let’s compare pogo pins and traditional connectors to find your best fit.

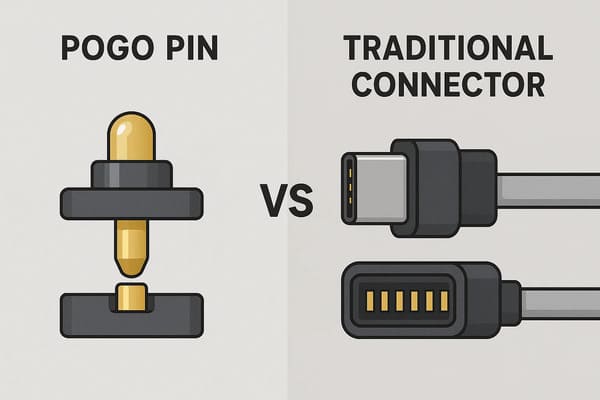

Pogo pins offer advantages like high durability, compact size, and excellent misalignment tolerance, making them suitable for demanding applications.

Traditional connectors are often cost-effective for simpler, less dynamic needs.

The ideal choice depends on the specific electronic application’s requirements for reliability and cost efficiency.

Now that you’re thinking about which connector path to take, it’s time to delve deeper.

By understanding the nuances of each, you’ll be better equipped to make an informed decision.

This choice benefits your design and product longevity.

Understanding the Basics: What are Pogo Pin Connectors and Spring Loaded Pins?

Unfamiliar with pogo pins? You might miss a superior connection solution.

Let’s explore what makes these innovative connectors unique and ideal for your next project.

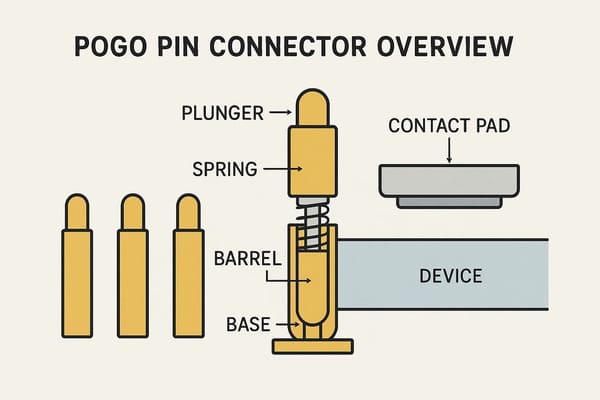

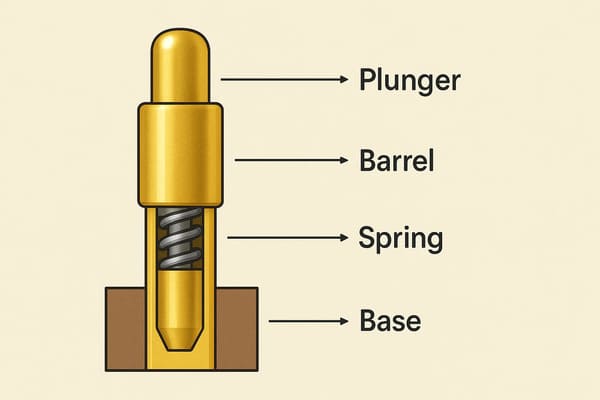

Pogo pins, also known as spring-loaded pins, are electrical connectors that utilize an internal spring mechanism for consistent, reliable contact.

They typically consist of a plunger, barrel, and spring.

This design offers durability, flexibility, and a compact form factor, making it suitable for a wide range of electronic devices.

Key Components and Functionality of Pogo Pins

Spring-loaded pins are amazing components.

I recall helping a client, Mark, with a wearable fitness tracker.

He needed a small, durable, and reliable charging solution.

Pogo pin connectors worked perfectly, solving his design challenge with ease.

They have three main parts:

-

Plunger (or Pin Head): This is the part that makes contact with the target surface, like a PCB pad.

It’s often gold-plated for optimal conductivity and corrosion resistance. -

Barrel (or Tube): This cylindrical component houses the spring and the plunger.

It acts as the main body of the pogo pin. -

Spring: Located inside the barrel, it provides the necessary constant force.

This force ensures the plunger maintains a secure electrical connection.

When a pogo pin is pressed against a contact pad, its internal spring compresses, ensuring consistent pressure and a stable electrical connection.

This design helps maintain contact even with minor misalignments or vibrations.

The ability of these components to create reliable connections in compact designs is a key advantage.

Exploring Traditional Connector Types and Their Uses

Traditional connectors seem familiar, but limitations in size or durability can hinder modern designs.

Let’s review common types and their typical applications for better understanding.

Traditional connectors, like USB or D-sub types, use fixed pins to mate with receptacles, providing cost-effective solutions for static connections.

While widely used, they can be bulkier and generally offer lower mating cycle durability than spring-loaded alternatives.

Their application is common where repeated connections are less critical.

Common Examples of Traditional Connectors

When most people hear "connector", they often picture traditional types.

These have been staples in electronics for decades.

They serve many purposes reliably across various industries.

Some common examples you’ll frequently encounter include:

-

Pin Headers and Sockets: These are very common on printed circuit boards (PCBs).

They are used for board-to-board or wire-to-board links.

They consist of rows of male pins and mating female sockets. -

USB Connectors: These are ubiquitous for data transfer and power delivery.

You find them in consumer electronics like smartphones, computers, and peripherals. Different USB types (A, B, C, Micro) serve various needs. -

D-sub Connectors: These are older, robust connectors.

They are often seen in industrial equipment and legacy computer peripherals like monitors or printers.

They are also used for communication ports such as RS-232. -

FPC/FFC Connectors (Flexible Printed Circuit/Flat Flexible Cable): These connect flexible circuits or flat cables to PCBs.

They are essential in compact devices where space is at a premium.

However, very high mating cycles are not usually their primary concern.

Traditional connectors use a male part with pins and a female part with sockets, needing precise alignment to avoid damage.

They’re cost-effective for static uses but bulkier than pogo pins and less durable for frequent mating.

I’ve seen them fail in projects needing daily reconnections, causing reliability issues.

Pogo Pin Connectors vs. Traditional Connectors: A Detailed Comparison for Your Needs

Choosing the right connector is crucial for any product.

When advising on connector technology, it’s important to align the choice with a product’s operational and design needs.

A mismatch can lead to failures or a poor user experience.

Let’s compare them directly on key factors for your pogo pin connector consideration.

Pogo pins offer superior durability, compact size, and tolerance for misalignment, often enhanced by magnetic features.

Traditional connectors, conversely, tend to be more cost-effective for stable, less demanding applications.

The optimal choice depends on specific project requirements, balancing factors like mating cycles and spatial constraints.

Feature-by-Feature Showdown

Choosing the right connector is crucial for any product, as a mismatch can cause failures or poor experiences.

Here’s a clear, comparative breakdown of pogo pins and traditional connectors:

| Feature | Pogo Pins (Spring Loaded Pins) | Traditional Connectors (e.g., Pin/Socket, USB) |

|---|---|---|

| Mating Process & Ease of Use | Simple press-to-mate; blind mating easily achievable | Often requires precise alignment; can be two-handed |

| Durability & Mating Cycles | Very high (e.g., 10,000 to over 1,000,000 cycles) | Lower (e.g., hundreds to a few thousands of cycles) |

| Contact Reliability (Vibration/Shock) | Excellent; constant spring force on contacts maintains connection | Can be susceptible to intermittent connection or disconnection |

| Tolerance for Misalignment | Good tolerance for angular and parallel misalignment | Low tolerance; requires precise alignment for mating |

| Size and Form Factor Flexibility | Highly compact; customizable shapes, pitches, and heights | Generally bulkier; often standard form factors |

| Electrical Performance | Good for moderate current/frequency; low stable resistance | Varies widely by type; can handle very high power/data |

| Environmental Sealing (Water/Dust) | Can be designed for IP ratings (water/dust resistance) | Sealing can be complex, add bulk, and increase cost |

| Cost | Higher initial cost per pin; system/longevity cost can be lower | Lower cost per pin for basic types; can be higher for specialized versions |

| Magnetic Option | Easily integrates magnets for self-aligning, secure mating (magnetic pogo pin connector) | Not a typical feature; specialized magnetic versions are rare/custom |

The choice between pogo pins and traditional connectors hinges on application needs.

Pogo pins offer superior durability, compact size, and ease of use, especially with magnetic features.

Traditional connectors, conversely, are often more cost-effective for stable, less demanding uses.

Prioritize key factors for optimal product performance.

Ideal Applications for Pogo Pins and Magnetic Pogo Pin Connectors

Unsure if pogo pins fit your product? You might miss benefits for space, durability, or easy connection.

Let’s explore ideal scenarios for these advanced spring loaded pin connectors.

Pogo pins are well-suited for applications demanding compact size, high mating cycles, or tolerance for misalignment.

They are commonly used in wearables, charging docks, medical devices, and test fixtures due to their durability and reliable contact.

Magnetic pogo pins further enhance ease of use with self-aligning features.

Top Uses for Pogo Pin Technology

-

Wearable Technology: Smartwatches, fitness bands, and AR/VR headsets need compact, durable, easy charging.

I recall a startup with smart glasses for industrial use.

They needed tiny, reliable charging for tough conditions.

Magnetic pogo pins provided secure, easy connections, even with gloves.

This application truly showcases the value of a magnetic pogo pin connector. -

Charging Docks: Laptops, tablets, and scanners benefit from the "drop and charge" ease pogo pins offer for power and data.

This enhances user convenience significantly, making daily interactions smoother. -

Medical Devices: Portable medical gear needs reliable, frequent connections.

Pogo pins offer this consistency and can be designed for easy cleaning, vital in healthcare environments.

Their reliability is paramount here. -

Test Jigs: In manufacturing, test equipment connectors face thousands of cycles.

Pogo pins are built for this endurance, ensuring long operational life and consistent test results. -

Ruggedized Devices: For harsh environments, pogo pin connectors offer good shock and vibration resistance.

Magnetic pogo pin connectors also aid quick, secure mating, which is crucial when visibility or dexterity is limited.

If an application requires compactness, high durability, simple mating, or accommodates movement, spring-loaded pin solutions are worth exploring.

These connectors can be tailored to meet precise specifications, offering reliable performance.

When Traditional Connectors Are the Right Choice

Pogo pin connectors are advanced, but are they always needed?

Over-engineering adds cost.

Let’s see where traditional connectors are still effective and preferred by some pogo pin connector buyers.

Traditional connectors are suitable for cost-effective projects with stable, less frequent connections and ample design space.

They are often preferred for internal links or standard input/output ports that do not require high mating cycles.

This makes them a practical choice when simplicity and budget are primary considerations.

Scenarios Favoring Traditional Connectors

-

Primary Cost Driver: For high-volume, low-cost consumer products with minimal connection cycles (e.g., connected once at assembly), standard pin headers or FPC connectors are often more economical from a bill-of-materials view.

-

Fixed Internal Connections: When connecting internal PCBs once during manufacturing, traditional connectors are adequate and cost-effective.

These connections are not meant for user interaction. -

Standardized Interfaces: If your product needs to use USB, HDMI, or Ethernet, you’ll use the corresponding traditional connector for compatibility with existing ecosystems and peripherals.

-

Specific Power/Signal Needs: Some specialized traditional connectors handle very high currents or specific high-frequency signals.

However, it’s worth noting that high-current pogo pins from a specialized pogo pin manufacturer are also improving constantly. -

Ample Space, Basic Mating: If space is plentiful and easy mating isn’t critical (like an internal service port), traditional connectors can work.

Their potentially bulkier nature might not be an issue.

It’s about the right tool for the job.

Not every design needs a premium pogo pin connector or a complex magnetic pogo pin connector.

Sometimes, a simple, well-understood traditional solution is the most sensible and efficient path.

Choosing Between Pogo Pin Connectors and Traditional Connectors for Your Application

Unsure which connector is best: pogo pin connector or traditional?

The wrong choice impacts product success.

Let’s summarize key considerations to help you decide.

When choosing connectors, evaluate mating cycles, available space, desired reliability, environmental conditions, and overall system cost.

Pogo pins are ideal for durability and user convenience, while traditional connectors suit budget-conscious, stable applications.

Careful analysis of these factors guides the best selection for your design needs.

Guiding Your Connector Decision: A Practical Checklist

-

Mating Cycles: How often will it connect/disconnect?

For hundreds or thousands, pogo pins are superior due to their high cycle life. -

Available Space: Is space tight?

Pogo pin connectors are compact and offer design flexibility. -

Misalignment/Vibration: Will it face misalignment or shock?

Pogo pins are more tolerant and maintain better contact. -

Environment: What conditions (dust, moisture)?

Specially designed pogo pins can offer excellent IP-rated sealing. -

Ease of Use: Is blind mating or magnetic self-alignment important for the user experience?

Magnetic pogo pins excel here. -

Budget: Consider total cost of ownership, not just initial price.

A durable pogo pin solution from a reliable pogo pin manufacturer can save money long-term through reliability and user satisfaction.

Always consider the complete scenario.

Opting for less expensive traditional alternatives might result in increased field failure rates, a less intuitive product, or design constraints.

An expert in connector solutions can assist you in evaluating these elements effectively.

Pogo Pin Connectors: Insights for Innovative Solutions

Finding a skilled partner for connector needs is crucial.

Expertise and quality solutions are available to support your spring-loaded pin connector requirements.

Pogo pins, also known as spring-loaded pins, are electrical connectors known for their durability and consistent electrical connections, even with mechanical shock and vibration. These connectors feature an internal spring, enabling reliable contact.

They are utilized in diverse electronic applications, including charging ports, data transfer, and testing equipment.

Key Considerations for Pogo Pin Connector Solutions

-

Tailored Customization: Look for providers who excel at creating custom solutions.

Whether you need specific dimensions, unique shapes, particular current ratings, or fully integrated magnetic connector assemblies, a strong R&D team can design and produce them, from initial ideas to mass production. -

Unwavering Quality Standards: A commitment to quality control is paramount. Reputable providers often implement robust management systems and adhere to strict quality control protocols. Certifications such as ISO9001, IATF16949 (automotive), ISO14001 (environmental), and ISO45001 (health & safety) indicate a strong dedication to quality. Additionally, ensure products meet relevant standards like CE, RoHS, and REACH.

-

Leveraging Advanced Technology: A focus on advanced technology, particularly in research and development, testing, and quality assurance, is a sign of a comprehensive solution pogo pin provider.

This allows for a genuine one-stop solution, encompassing product design, precision molds, automated assembly, visual inspection, and comprehensive testing. -

Broad Industry Experience: Partnering with a provider experienced in serving diverse industries, including consumer electronics, smart homes, aerospace, medical equipment, automotive electronics, and IoT, can be beneficial.

Their global reach and experience can add significant value to your project

Choosing the right connector partner involves evaluating their ability to offer customized, high-quality, and technologically advanced solutions.

Prioritize those with broad industry experience to ensure your project benefits from comprehensive support and expertise.

Making Your Final Connector Decision: Pogo Pins or Traditional?

Ready for your final connector choice? It can be daunting.

Let’s recap key takeaways to help you select the optimal connection technology for your product.

For your final connector decision, pogo pins offer enhanced durability and flexibility, ideal for dynamic or compact applications.

Traditional connectors may be suitable for simpler, static, or cost-sensitive uses.

Evaluate your project’s specific needs for performance, space, and user experience to determine the optimal choice.

Your Next Step in Connector Selection

You’ve explored the detailed differences, advantages, and ideal use cases for both pogo pins and traditional connectors.

The ultimate choice truly hinges on the unique demands, environmental factors, and user experience priorities of your specific application.

It’s a critical decision that impacts your product’s success.

If your product requires:

- Exceptional Durability: These connectors are engineered to endure extensive use, reliably performing through thousands to millions of connection cycles.

This makes them a robust option for long-lasting product designs. - Highly Compact Design: Their inherently small form factor enables sleeker product designs and more efficient internal space utilization.

This is particularly beneficial for miniaturized electronic devices where space is at a premium. - Reliable Connectivity: They maintain stable electrical contact even when faced with minor misalignments or challenging high-vibration conditions.

This consistent connection helps ensure product functionality and user satisfaction. - Enhanced User Experience: Features like blind mating and magnetic assistance simplify connections, providing a seamless and satisfying user interaction.

This can significantly improve the overall usability of a device.

Making an informed connector choice ensures your product meets its performance goals and delights users.

Consider these insights to select the optimal connection technology for your specific needs, paving the way for successful innovation.

Conclusion

Choosing the right connector is vital. Pogo pins offer modern advantages.

For expert advice on quality pogo pin solutions, contact CTP or visit our homepage.