Are you battling unreliable connections in tight PCB designs?

It’s frustrating when performance issues derail your project.

Traditional connectors often fail in compact spaces.

Let’s explore how pogo pin solutions can transform your designs with lasting reliability.

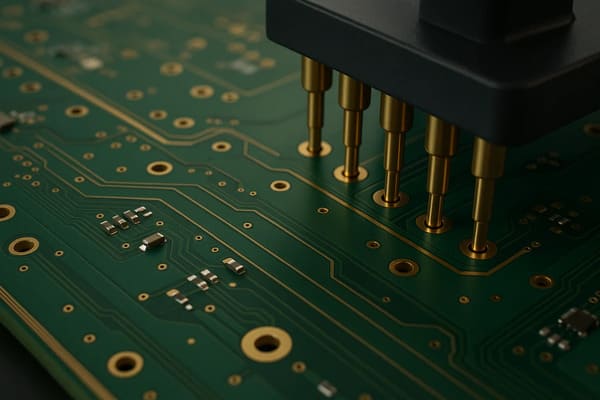

Pogo pins integrate best by offering a direct solution for high-density PCB challenges.

These spring-loaded contacts deliver consistent pressure, ensuring stable electrical paths even under vibration or misalignment.

This approach enhances signal integrity and durability for compact devices, leading to seamless performance.

Keep reading to uncover practical strategies.

I’ll share insights on how the pogo pin market can elevate your design process and secure a competitive edge in electronics.

Why Are High-Density PCB Connections a Challenge with Pogo Pins?

Feeling squeezed by shrinking PCB real estate?

High-density designs push limits, and conventional connectors often struggle to keep up.

It’s a common struggle for engineers aiming for compact yet robust products, where integrating pogo pins effectively becomes crucial in today’s fast-paced tech world.

In high-density PCB connections, spring-loaded pins face hurdles like limited space and complex signal paths.

Traditional connectors might be too large, and achieving precise alignment can increase rework.

Additionally, maintaining durability with frequent use and ensuring signal integrity at higher frequencies are key considerations.

Let’s dive deeper into these obstacles.

I’ll break down the specifics to help you navigate pogo pin integration with confidence and precision.

Miniaturization Demands and Connector Limitations

Space is at a premium in modern electronics.

As devices shrink, finding room for connections becomes a puzzle.

A precision pogo pin factory can provide insights into overcoming these barriers.

- Space Constraints: Traditional connectors often have large footprints, stealing PCB real estate.

This makes achieving the desired density tough.

Switching to compact spring-loaded pin solutions can free up critical space for other components. - Assembly Complexity: Aligning and soldering in tight spaces is tricky.

Misalignment leads to rework or damage.

Such precision slows production, but innovative spring probes from experienced providers simplify the process with better tolerance. - Durability Concerns: Many connectors aren’t built for high mating cycles.

In applications like charging ports, wear happens fast.

Durable pogo pin connector options are engineered for longevity, reducing failure rates. - Signal Integrity Risks: High-frequency signals expose impedance mismatches and crosstalk.

This corrupts data in dense setups.

Solutions from a versatile spring loaded pin supplier maintain cleaner transmission through optimized designs.

I’ve seen these challenges firsthand in countless projects.

Addressing them early with the right tools can save time and cost.

Let’s explore more on how these connectors redefine reliability.

What Makes Pogo Pins Ideal for High-Density Applications?

Ever wondered how to achieve rock-solid connections in tiny spaces?

Pogo pins, or spring-loaded contacts, are game-changers for compact electronics.

Their unique design tackles many traditional connector flaws head-on.

Pogo pins are ideal for high-density applications due to their compact design and reliable performance.

Comprising a plunger, barrel, and spring, they maintain constant contact force against mating surfaces.

This ensures stable electrical paths, making them well-suited for tight spaces and high-density assemblies.

Stick with me to uncover detailed advantages.

These insights can reshape how you approach pogo pin connector integration for lasting performance.

Pogo Pin Advantages: Reliability and Performance in Your Designs

Designing for tight spaces requires connectors that won’t fail.

The right components make all the difference in achieving robust outcomes.

Let’s dive into why these spring probes stand out.

- Superior Contact Mechanism:

- Consistent Spring Force: The internal spring delivers steady pressure across its travel range.

This ensures stable electrical contact despite height variations.

It’s a key edge over rigid connectors, as highlighted by many precision pogo pin suppliers. - Self-Cleaning Wiping Action: During compression, the plunger slightly rotates, wiping the contact surface.

This breaks through oxides or debris over time. Such a feature maintains low resistance in dusty conditions. - Tolerance Compensation: Manufacturing variances are inevitable in PCB assembly.

These pogo pin contacts adjust individually to uneven surfaces, ensuring all connections are properly made.

- Consistent Spring Force: The internal spring delivers steady pressure across its travel range.

- Impressive Durability and Cycle Life:

- High Mating Cycles: Built for tens of thousands of connections, these spring-loaded pin connectors outlast many alternatives.

Ideal for charging ports or test fixtures, they endure frequent use, cutting replacement costs significantly. - Robust Construction: Made from quality materials like brass and gold plating, they resist corrosion.

Such choices ensure lasting performance.

- High Mating Cycles: Built for tens of thousands of connections, these spring-loaded pin connectors outlast many alternatives.

- Unwavering Shock and Vibration Resistance:

- Spring-Loaded Resilience: The design maintains contact under stress like jolts or shakes.

Unlike rigid options, pogo pin connectors don’t disconnect easily, suiting portable devices or automotive uses.

- Spring-Loaded Resilience: The design maintains contact under stress like jolts or shakes.

- Remarkable Space Efficiency and Miniaturization:

- Compact Footprint: With small diameters, they pack densely on PCBs.

This maximizes connection points in limited areas.

Many engineers rely on customizable spring loaded pin connectors for such efficiency. - Enabling Thinner Designs: Without bulky housings, pogo pin contacts support sleeker profiles, perfect for wearables or smartphones, driving modern aesthetics.

- Compact Footprint: With small diameters, they pack densely on PCBs.

- Excellent Electrical Performance:

- Low Contact Resistance: Gold-plated options keep resistance minimal, cutting power loss.

Heat generation stays low, critical for dense setups.

Experts in the field note this as a core advantage. - Good Signal Integrity: Short signal paths reduce inductance for high-speed data.

They support controlled impedance needs, with designs available for RF applications. - High Current Carrying: Variants handle significant loads, from signals to power.

Versatility like this fits diverse projects.

Industry know-how suggests selecting based on specific current needs.

- Low Contact Resistance: Gold-plated options keep resistance minimal, cutting power loss.

- Streamlined Assembly and Rework:

- SMT Compatibility: Designed for automated surface mount processes, these spring probes cut labor costs.

Integration into standard lines is seamless. - Reduced Alignment Precision: Springs forgive minor misalignments during assembly.

Yields improve, and rework drops. Such practical benefits are often shared by experienced providers. - Simplified Repair: Pressure-based connections allow easy module swaps without desoldering.

This boosts modularity and repair speed. Field insights underline its value for maintenance.

- SMT Compatibility: Designed for automated surface mount processes, these spring probes cut labor costs.

- Unmatched Flexibility and Versatility:

- Customizable Designs: Tailored lengths, forces, or tip styles meet unique needs.

Engineers can optimize these pogo pin designs for specific uses. - Wide Range of Applications: From battery contacts to test fixtures, pogo pin connectors adapt widely.

Their reach spans consumer to industrial sectors, highlighting their adaptability.

- Customizable Designs: Tailored lengths, forces, or tip styles meet unique needs.

These benefits pave the way for smarter designs.

Let’s keep exploring how to integrate pogo pin contacts effectively for maximum impact.

How to Achieve Successful Pogo Pin Integration in Designs?

Tackling connector integration in tight electronics can feel daunting.

Making informed choices early prevents costly redesigns.

Let’s uncover actionable steps to ensure pogo pin success in your projects.

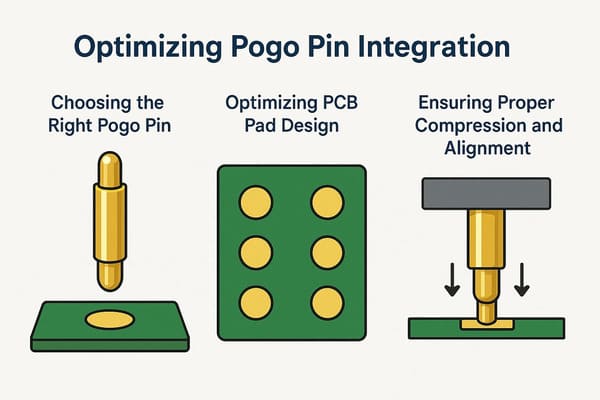

Achieving successful pogo pin integration involves strategic selection and optimized PCB layouts.

Key considerations include evaluating environmental factors such as heat and moisture, which impact long-term reliability.

Partnering with an experienced supplier for cost-effective and durable solutions is also crucial.

Why does this matter so much?

Let’s break it down further.

These strategies can redefine how you approach pogo pin setups in demanding applications.

Design Phase Best Practices: Laying the Groundwork

Starting strong sets the tone for flawless execution.

Thoughtful planning during design avoids pitfalls later.

Critical input on spring loaded pin options can guide this process effectively.

-

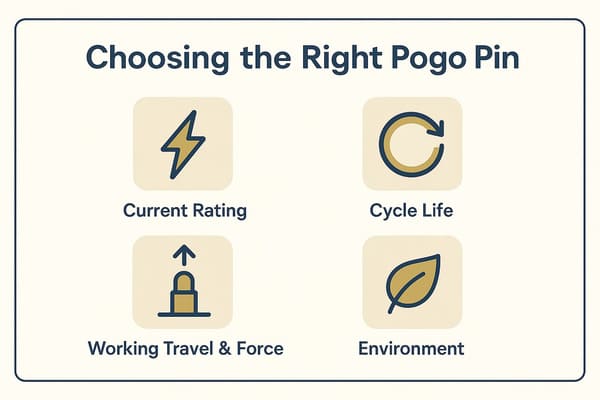

Choosing the Right Pogo Pin:

- Current Rating: Ensure it handles power needs without overheating.

High-current options exist for robust applications.

Industry expertise suggests matching specs closely to avoid risks. - Cycle Life: Align rated cycles with product usage.

Test fixtures demand higher endurance than static modules.

Experience indicates this prevents early failures in frequent-use scenarios. - Working Travel & Force: Pick pins with suitable travel for tolerances.

Balanced force prevents component stress.

Insights from makers stress operating within optimal ranges. - Environment: Factor in dust or moisture exposure.

Sealed or specialized pins may be necessary.

Practical advice points to tailored solutions for harsh conditions.

- Current Rating: Ensure it handles power needs without overheating.

-

Optimizing PCB Pad Design:

- Pad Material & Finish: Gold-plated pads ensure low resistance and durability.

They pair well with similar pin finishes.

Field know-how recommends this for consistent contact. - Pad Size & Shape: Design pads to fit plunger tips, allowing slight misalignment.

Larger pads aid wiping action.

Experts often suggest prioritizing flatness for reliability. - Pad Flatness (Coplanarity): Even surfaces promote uniform contact across arrays.

Uneven pads risk poor connections.

Practical tips focus on precision in pad layout for best outcomes.

- Pad Material & Finish: Gold-plated pads ensure low resistance and durability.

-

Ensuring Proper Compression and Alignment:

- Recommended Working Height: Operate within specified compression ranges for longevity.

Over or under-compression harms performance.

Insights highlight adherence to maker guidelines. - Mechanical Guidance: Use guide pins or housing features for blind mating.

This aids high-density arrays.

Based on project feedback, such alignment tools boost assembly success.

- Recommended Working Height: Operate within specified compression ranges for longevity.

Planning with these principles streamlines later stages.

Let’s move into other factors that influence spring loaded pin connector performance over time.

Critical Environmental Factors

Conditions around your device impact the connector life.

Ignoring them risks premature failure.

Seeking specialized advice for these challenges can be very beneficial.

- Temperature: Pins have defined thermal ranges.

Extreme heat or cold affects spring behavior.

Selecting rated options, as advised by industry know-how, ensures steady operation. - Humidity and Moisture: Corrosion threatens in damp settings.

Gold plating helps, but sealed or IP-rated pins excel in wet conditions.

Practical experience recommends protective features for reliability. - Contamination: Dust or chemicals can disrupt even self-cleaning contacts.

Shrouds or regular cleaning mitigate risks.

Field insights suggest enhanced designs for dirty environments.

Addressing these elements safeguards long-term function.

Let’s shift to evaluating the financial side of pogo pin integration for a fuller picture.

Realistic Cost-Benefit Analysis

Balancing cost with performance is crucial in B2B decisions.

A thorough look at expenses reveals true value.

Partnering with an experienced pogo pin factory can clarify these trade-offs.

- Initial Cost: Compare pin prices against traditional connectors.

Upfront costs vary by type and customization.

Industry perspectives note that quality often justifies a higher start. - Assembly Cost: Factor in savings from SMT ease and less rework.

Automation cuts manual effort.

Experience shows this offsets initial spends in high-volume runs. - Reliability & Warranty Costs: Higher dependability reduces field issues.

Fewer failures mean lower claims.

Experts highlight how this builds client trust over time. - Performance Gains: Value benefits like miniaturization or signal clarity.

Enhanced user experience adds market edge.

Practical input suggests weighing these against budget constraints. - Total Cost of Ownership (TCO): Long-term, pogo pin solutions often cost less.

Reliability and efficiency drive savings.

Field data supports choosing based on overall lifecycle value.

Looking at the bigger financial picture guides smarter choices.

These insights equip you to optimize spring loaded pin connector use effectively.

Conclusion

In summary, pogo pin integration offers unmatched reliability and space efficiency for high-density designs.

These tips empower your projects with durable, performance-driven solutions.

For tailored options, explore our homepage or reach out via our contact page.

We’re eager to support your next innovation in the pogo pin space.