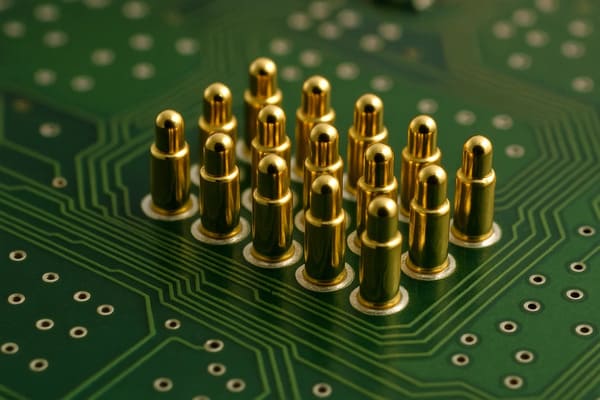

Are you battling unreliable connections in your devices?

It’s frustrating when performance falters.

Poor electrical contact can ruin product quality and hurt your reputation.

The fix lies in optimizing the pogo pin spring design and contact force for consistent results.

Spring design directly impacts a spring-loaded pin’s contact force, which is crucial for optimal performance.

The spring’s compression and material determine the consistent force applied, ensuring stable electrical connections.

Proper design prevents intermittent contact and enhances durability, leading to reliable device functionality across various applications.

Let’s dive deeper into this critical topic.

Keep reading to explore how the pogo pin market can boost your product’s success with tailored design insights.

How Does Spring Design Influence Pogo Pin Contact Force?

Ever wondered why some connections fail under pressure?

Unstable contact force in a pogo pin connector can disrupt signals and frustrate users.

It’s a common issue in high-stakes applications.

Solving it starts with understanding spring mechanics.

Spring design significantly influences the contact force of a spring-loaded pin by dictating its compression characteristics.

A precisely engineered spring maintains consistent pressure, which is vital for stable electrical conductivity.

This consistent force mitigates signal degradation and ensures dependable performance, even when subjected to mechanical stress.

Curious about the specifics?

Let’s break it down further.

These insights will reshape how you approach pogo pin integration in your next project.

Defining the Two Main Forces

Getting the basics right sets the foundation.

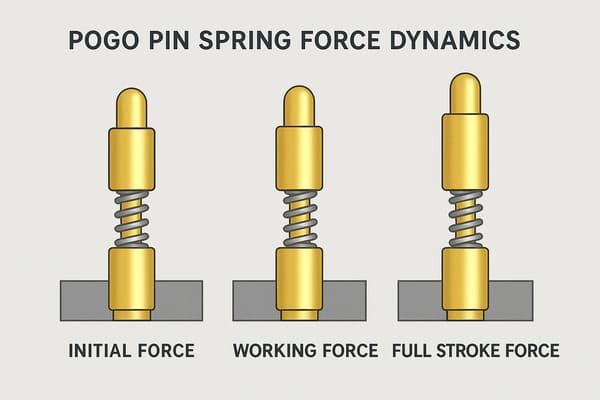

The spring force in a pogo pin connector varies at different compression stages.

Each stage plays a unique role in performance.

- Initial Force: This is the starting force needed to begin contact.

It’s light but crucial for the first connection.

A versatile pogo pin supplier ensures this force is just enough to initiate without strain, preserving component life over countless cycles. - Working Force: This is the ideal force during regular use.

It keeps the connection stable.

Based on industry expertise, this level should match your device’s typical load to avoid drops in performance during operation. - Full Stroke Force: This is the peak force when fully compressed.

It tests the limits of durability.

Experience shows that exceeding this often risks permanent damage, so careful calibration is key. - Understanding Force-Deflection Curves: These curves map how force changes with compression.

They guide precise design.

Experts in the pogo pin factory suggest using these graphs to predict behavior and select springs for specific needs.

Let’s wrap this up with a quick note. Balancing these forces ensures long-term reliability.

Stick with us to uncover why contact force can’t be overlooked.

Why Is Contact Force Non-Negotiable?

Picture this: a critical device fails due to a weak connection.

It’s a nightmare for any business.

Contact force in spring loaded pin connectors is the backbone of consistent performance.

- Ensuring a Stable Connection: Strong contact force keeps the link unbroken during operation.

It stops annoying signal drops.

Experts from a precision pogo pin supplier stress that this stability is vital for seamless data or power flow in any device. - Overcoming Electrical Resistance: Proper force pushes through surface barriers for better current flow.

It ensures efficiency.

Industry insights suggest this minimizes loss, keeping conductivity high even under challenging electrical loads over time. - Resisting Vibration and Shock: Adequate force holds firm against external jolts or shakes.

It preserves the bond.

Based on field experience, this is critical in automotive or industrial settings where movement is constant and reliability is non-negotiable. - Preventing Fretting Corrosion: Steady force limits micro-motions that degrade contacts over cycles.

It extends lifespan.

Practical know-how shows that curbing this wear prevents surface damage, saving costs on frequent replacements in the long run.

Let’s keep exploring. Understanding this importance shifts your perspective on design.

Join us to dive into the anatomy of springs next.

What Are the Key Design Factors in a Pogo Pin Spring?

Designing a pogo pin spring isn’t just guesswork.

Small flaws can lead to big connection issues down the line.

Getting the structure right is everything for lasting performance.

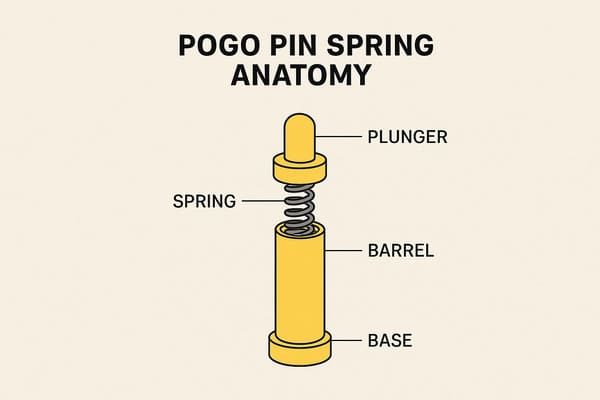

Key design factors in a spring-loaded pin include material composition, wire diameter, coil count, and spring constant.

These elements collectively determine the spring’s compression characteristics, affecting contact force and overall durability.

Optimizing these factors ensures reliable electrical connections and extends the operational lifespan of the pin within its intended application.

Ready for a closer look?

These details will transform your approach to spring loaded pin connectors.

Follow along as we unpack the science behind it.

The Science of Spring Materials

Materials shape a spring’s behavior in unique ways.

Choosing wisely can make or break a pogo pin’s performance.

Let’s explore common options.

- Stainless Steel: This material offers excellent resilience in challenging environments.

It effectively resists corrosion and wear over time.

Professionals designing spring-loaded pins often find it suitable for outdoor or humid applications, ensuring long-lasting connection integrity. - Music Wire: Known for enduring repeated stress, it’s a top pick for dynamic uses.

It handles constant compression without deforming.

Industry insights suggest this works best in high-cycle devices like wearables or handheld tools. - Beryllium Copper: Perfect for electrical efficiency, it combines flexibility with conductivity.

This choice excels in high-current needs.

Based on extensive experience, this material suits precision electronics where signal clarity is critical.

Time to tie this together.

Material selection is a game-changer for tailored solutions.

Let’s move to the specifics of spring structure next.

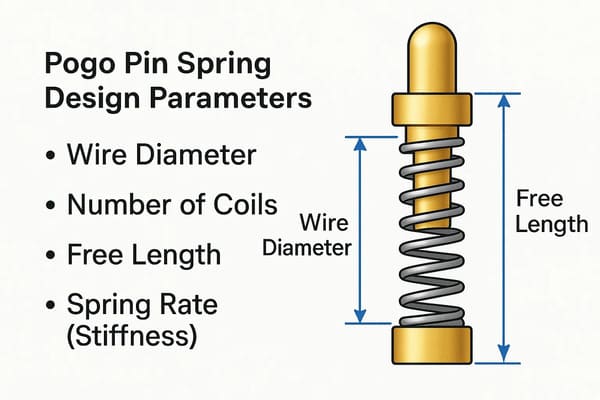

Key Spring Parameters and Their Impact

Beyond material, a spring’s build matters.

Each parameter tweaks how a spring loaded pin connector performs.

Let’s break down the essentials.

- Wire Diameter: Thicker wires mean a stronger force but less flexibility.

It’s a balance.

Industry know-how shows that adjusting this ensures the right push for stable contact in varied applications like automotive or IoT devices. - Number of Coils: More coils often reduce stiffness for smoother travel.

Fewer coils make it rigid.

Insights from a premier pogo pin supplier suggest matching coil count to your device’s compression needs for optimal response. - Free Length: This is the spring’s uncompressed length.

It sets how far it can compress.

Experts advise that a longer free length offers more travel, fitting for applications needing deep engagement without strain. - Spring Rate (Stiffness): This measures the force increase per compression unit.

It guides predictability.

Based on field experience, a steady rate helps maintain consistent performance across batches in mass production.

Let’s pause for a quick reflection.

Fine-tuning these aspects ensures precision.

Up next, see how customization takes it further.

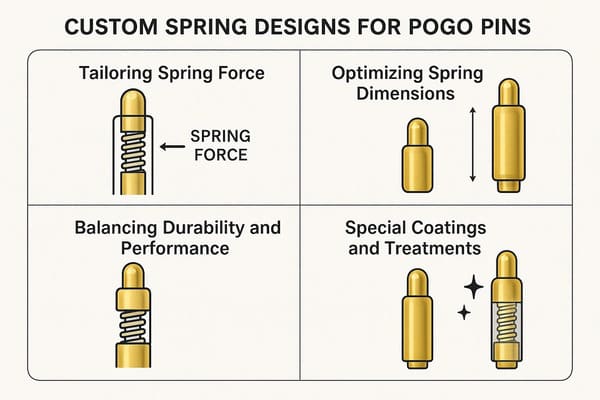

Customization for Specific Applications

Standard designs don’t always fit the bill.

Tailoring a pogo pin connector to your exact needs can boost outcomes.

Customization is often the answer.

- Tailoring Spring Force: Adjusting the force ensures perfect contact in unique scenarios.

Think medical devices needing a gentle touch.

Industry expertise recommends calibrating force to avoid overstress, enhancing device safety and user experience. - Optimizing Spring Dimensions: Small devices demand compact springs without losing power.

Wearables are a prime example.

Specialists suggest shrinking dimensions smartly to fit tight spaces while maintaining robust connection strength. - Balancing Durability and Performance: Longevity matters as much as immediate function.

It cuts replacement costs.

Based on proven practices, striking this balance means springs endure high cycles without sacrificing contact reliability. - Special Coatings and Treatments: Coatings like gold or nickel protect against harsh conditions.

They extend life in tough environments.

Experience indicates these treatments are vital for marine or industrial uses where exposure risks damage.

Let’s wrap this section.

Custom solutions open new possibilities.

Join us to explore actionable tips for peak performance.

How Can You Optimize Pogo Pin Performance as a B2B Buyer?

Struggling to get the best from your spring probes?

Many buyers overlook key steps that elevate reliability.

Optimizing performance isn’t as complex as it seems.

Optimizing spring-loaded pin performance as a B2B buyer involves precisely calculating the required contact force based on application needs.

Focus on selecting pins with appropriate spring constants and materials to ensure stable connections.

Collaborating with suppliers to align specifications with operational demands is crucial for consistent reliability and longevity.

Eager to refine your approach?

These tips will redefine your sourcing process.

Stay with us to learn proven methods for better outcomes.

Calculating the Ideal Contact Force

Precision in contact force is a must.

It’s the core of a stable spring loaded pin connection.

Here’s how to get it right.

- Application-Specific Requirements: A wearable needs light force, while automotive demands robust push.

Match force to purpose.

Industry insights suggest mapping exact operational needs first to avoid under- or over-force issues in deployment. - Balancing Force with Travel: Too much force shortens travel; too little risks disconnects.

Find the sweet spot.

Experts recommend testing compression depth against force to ensure seamless operation without mechanical strain over time. - Accounting for Tolerances: Manufacturing variances can affect outcomes.

It’s wise to plan for slight deviations.

Based on extensive knowledge, incorporating tolerance buffers helps ensure every spring loaded pin performs reliably, even in large-scale production runs. - Leveraging Supplier Expertise: It’s beneficial not to tackle this alone.

Partnering with experienced providers can offer tailored advice.

Field experience indicates that close collaboration on specifications often reveals valuable design improvements for your pogo pin connector project.

Let’s take a moment here.

Getting force right sets a strong foundation.

Next, see a real-world example of this in action.

Case Study: High-Current Spring Design

Real examples show what works.

High-current applications test a pogo pin’s limits.

Here’s how design meets demand.

- Using High-Conductivity Materials: Materials like beryllium copper cut resistance for heavy loads.

It keeps signals clear.

Industry practice highlights choosing such materials to handle high power without overheating or loss in critical systems. - Increasing Effective Contact Area: Larger contact zones spread current to prevent hot spots.

It boosts safety.

Experts note that wider tips or flat heads in design evenly distribute load, reducing wear in demanding setups. - Managing Thermal Rise: High current generates heat that can damage components.

Control it early.

Based on field tests, proper spring and plating choices dissipate heat, protecting long-term function in intense environments. - Example with Spring-in-Series: Pairing springs can handle more current without strain.

It’s a smart tweak.

Practical experience suggests this setup in a pogo pin contact design increases capacity, as seen in EV charging interfaces.

Let’s connect the dots.

High-current needs show why design matters.

Stick around for more factors to consider.

Beyond Contact Force: Other Considerations

Contact force isn’t the full story.

Other elements shape how a spring probe performs.

Let’s cover these vital extras.

- Minimizing Electrical Resistance: Gold or silver plating cuts resistance for better flow.

It sharpens efficiency.

Industry tips point to selecting coatings that match conductivity needs, ensuring minimal signal loss in precision electronics. - Achieving Mechanical Stability: Misalignment breaks connections over time.

Design prevents this.

Experts advise incorporating guiding structures in a pogo pin contact to maintain alignment under vibration or repeated use. - Ensuring Proper Engagement: Tip shapes like pointed or flat affect contact quality.

Choose wisely.

Based on hands-on insights, matching tip style to mating surface ensures full engagement without undue wear or slippage. - Partnering with a Reliable Manufacturer: A dependable provider ensures every batch meets specs.

It saves headaches.

Experience underlines that collaborating with a proven manufacturer secures consistent quality, vital for B2B trust and scalability.

Let’s round this off.

These factors complete the performance puzzle for spring-loaded pins.

Keep reading as we conclude with key takeaways.

Conclusion

Mastering spring design and contact force is key to unlocking pogo pin reliability.

This knowledge empowers your business with durable, efficient connections.

For tailored solutions in the pogo pin space, explore our homepage or reach out via our contact page.

We’re here to support your next project.