Imagine your project halted by a faulty connector.

Magnetic pogo pin connectors ensure reliable connections, but picking the wrong one risks costly failures.

How can you choose wisely?

To choose the right magnetic pogo pin connector, evaluate essential specifications such as size, pin count, and current capacity.

Consider environmental factors that necessitate features like waterproofing or enhanced durability.

Verifying compatibility and performance through sample testing is also crucial for ensuring reliable integration.

This guide aims to help you select an appropriate magnetic pogo pin connector for your project, focusing on reliability and efficiency.

The right connector choice can significantly impact a design’s long-term success.

Why Should You Consider Magnetic Pogo Pin Connectors for Your Design?

Struggling with unreliable or clumsy connections?

Traditional connectors can be fiddly and wear out quickly.

Magnetic pogo pins offer a simpler, more robust solution for many modern devices.

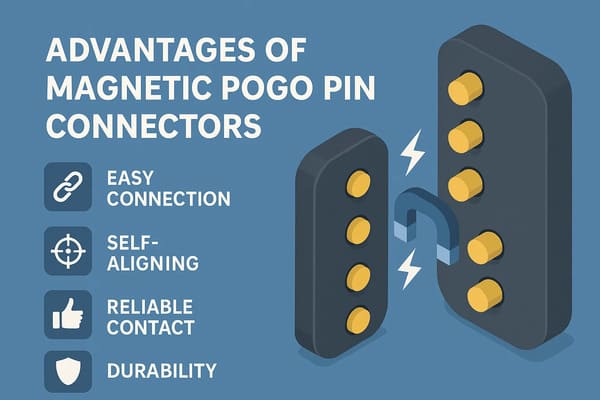

Magnetic pogo pin connectors offer reliable, secure, and intuitive connections for electronic designs.

Their magnetic alignment ensures effortless mating, reducing wear and enhancing durability.

This design also provides a safe breakaway feature, preventing damage from accidental disconnections.

They are suitable for various applications, including consumer electronics and medical devices.

These innovative connectors offer significant technical advantages, extending beyond mere convenience.

Understanding their benefits provides valuable insights for optimizing various electronic designs.

The Unique Appeal of Magnetic Pogo Pins

Magnetic pogo pin connectors have become increasingly popular, and for good reason.

I remember a client who was developing a new wearable device.

They were frustrated with the traditional USB port‘s bulkiness and the connection’s occasional flakiness.

Switching to a custom magnetic pogo pin connector, designed by our team at CTP, not only improved the device’s aesthetics but also its charging reliability.

Here’s why they are so appealing:

- Ease of Use: The primary advantage is the effortless connection.

Magnets guide the connector into place, creating a secure link almost automatically.

This is great for devices that need frequent connections, like charging ports. - Enhanced Durability: With no mechanical latches or parts that need to be forced together, there’s less wear and tear.

This means a longer lifespan for both the connector and the device. - Improved Safety: If a cable connected via a magnetic pogo pin is accidentally yanked, it tends to detach cleanly.

This can prevent damage to the device or the port, unlike traditional connectors that might break or pull the device off a surface. - Design Flexibility: These connectors can be designed in various shapes and sizes, allowing for sleek, low-profile integrations.

This is a huge plus for compact devices where space is at a premium. - Sealing Capabilities: Magnetic pogo pins can be easily designed to be waterproof and dustproof, crucial for ruggedized devices or medical equipment.

These benefits make magnetic pogo pin connectors a compelling choice for engineers seeking reliable and user-friendly solutions.

Their adaptability ensures they meet the demands of various modern electronic products.

What Essential Factors Should You Consider When Choosing Magnetic Pogo Pin Connectors?

Overwhelmed by all the connector specifications?

Choosing the wrong magnetic pogo pin connectors can seriously derail your project and budget.

It’s vital to focus on the key factors to ensure optimal performance and reliability for your specific needs.

Choosing magnetic pogo pin connectors requires evaluating several factors.

Consider electrical specifications like current and voltage ratings, alongside mechanical needs such as mating cycles and force.

Environmental resilience, including temperature range and IP rating, is also crucial for durability. Additionally, assess size constraints, magnetic holding force, and the overall quality standards of the components.

Understanding these types helps in defining specific needs.

This knowledge allows for a more informed discussion when sourcing components, ensuring the chosen connector meets precise application requirements.

It contributes to a smoother selection process.

Understanding Different Pogo Pin Types

The first step in selecting a suitable spring loaded pin connector involves understanding its electrical performance.

It’s essential to define the electrical needs for the application.

This ensures the chosen component can safely handle the required power and signal integrity.

| Pogo Pin Type | Key Characteristic | Common Use Case |

|---|---|---|

| Standard Pogo Pin | Simple: needle, spring, tube | General connections |

| Sealed Pogo Pin | Water/dust resistant (sealing ring) | Harsh environments, medical devices |

| Pointed Pogo Pin | Sharp needle tip | High-density, small pitch |

| Flat Head Pogo Pin | Flat needle tip, large contact area | High current transmission |

| Round Head Pogo Pin | Sleek needle tip, reduces wear | Frequent plugging/unplugging |

| SMT Pogo Pin | Surface mount for PCB | Automated production |

| THT Pogo Pin | Through-hole mount for PCB | Manual or semi-auto production |

| Magnetic Pogo Pin | Added magnetic material | Easy, secure, self-aligning |

Knowing these types helps you better define what you need when talking to a precision-made pogo pin supplier.

Electrical Requirements for Your Pogo Pin Connector

The first thing I always ask clients is about their electrical needs.

- Current Rating (Amps): How much current does the pogo pin connector need to carry safely without overheating?

This is critical for power applications. - Voltage Rating (Volts): What is the maximum voltage the pogo pin connector will handle?

- Contact Resistance: Lower is better. High resistance can lead to power loss and heat generation.

- Signal Integrity: For high-speed data transfer, the pogo pin connector must maintain signal quality.

This involves impedance matching and shielding if necessary.

Mechanical Requirements of Pogo Pin Connectors

How will the connector be used physically?

- Mating Cycles: How many times will the connector be plugged and unplugged during its lifespan?

Our durable pogo pins can handle high cycle counts. - Operating Force / Spring Force: The pogo pins need enough spring force for a reliable connection but not so much that it’s hard to mate or causes excessive wear.

- Vibration and Shock Resistance: Crucial for devices used in mobile or industrial environments.

- Alignment Tolerance: How much misalignment can the pogo pin connector tolerate while still ensuring a good connection?

Magnetic assistance helps here.

Environmental Conditions for Pogo Pins

Where will your product be used?

- Temperature Range: Consider both operating and storage temperatures.

- Humidity Resistance: Will the device be exposed to high humidity?

- Waterproof/Dustproof (IP Rating): If your device needs protection against water or dust, you’ll need a connector with an appropriate IP rating (e.g., IP67, IP68).

- Corrosion Resistance: For harsh environments, materials resistant to salt spray or chemicals are essential.

Size and Shape Constraints for Magnetic Connectors

Space is often a luxury in modern electronics.

- Overall Dimensions: Length, width, and height limitations.

- Pin Pitch: The distance between pins.

- Mounting Style: Surface Mount (SMT) or Through-Hole (THT) are common.

- Form Factor: Circular, rectangular, or a custom shape to fit your product design.

Magnetic Force in Pogo Pin Connectors

For magnetic connectors, the magnet’s role is key.

- Holding Force: The magnets should be strong enough to maintain a stable connection but allow for easy detachment when intended.

- Alignment Strength: The magnets should effectively guide the connector halves for proper alignment of the pogo pins.

- Consideration for Unintentional Detachment: Is a break-away feature desirable for safety?

Reliability and Quality Standards from Your Pogo Pin Supplier

Always vet your supplier.

- Manufacturer Certifications: Look for ISO9001, IATF16949 (for automotive), ISO14001 (environmental).

- Product Compliance: Ensure products meet RoHS, REACH, and other relevant standards.

- Testing Procedures: A reliable pogo pin manufacturer will have rigorous testing.

Cost Considerations for Magnetic Pogo Pin Connectors

Finally, the budget.

- Unit Price: The cost per connector.

- Tooling Costs: Custom designs often involve initial tooling investment.

- Total Cost of Ownership: Consider long-term costs, including potential failures if you choose a cheaper, lower-quality option.

- Volume Discounts: Ask about pricing for larger quantities.

Selecting the right magnetic pogo pin connector is essential for project success.

By thoroughly considering these factors, you can ensure the chosen components provide optimal performance and long-term reliability.

Prioritizing these aspects helps avoid common pitfalls in connector selection.

What is the Step-by-Step Process for Selecting the Ideal Magnetic Pogo Pin Connector?

Feeling lost in the selection maze for your pogo pin buyer needs?

A structured approach prevents costly missteps.

Follow these steps to confidently choose the right magnetic pogo pin connector for your project.

The process for selecting magnetic pogo pin connectors involves several steps.

Begin by defining specific project requirements, followed by researching potential suppliers. Next, request and thoroughly test samples to evaluate performance.

Finally, place mass production orders after successful validation, ensuring clear communication throughout.

This guide outlines a practical approach to selecting the right magnetic pogo pin connector.

It details how to assess your project’s needs, evaluate available options, and test prototypes to ensure optimal performance.

A Practical Guide to Choosing Your Magnetic Pogo Pin Connector

Selecting the right connector is a methodical process, especially for projects requiring tailored solutions.

This guide will walk you through each phase, ensuring you make an informed choice. It covers everything from defining needs to final selection.

-

Phase 1: Clearly Define Your Project Needs

- List Specifications: Detail all your electrical (current, voltage), mechanical (mating cycles, spring force), and environmental (temperature, IP rating) requirements.

The more specific you are, the better. - Application Context: How and where will the end product be used? Who is the end-user?

This impacts design choices for the magnetic pogo pin connector. - Prioritize: What are the absolute "must-have" features, and what are "nice-to-haves"?

This helps in making trade-offs if needed.

- List Specifications: Detail all your electrical (current, voltage), mechanical (mating cycles, spring force), and environmental (temperature, IP rating) requirements.

-

Phase 2: Research and Shortlist Potential Pogo Pin Suppliers

- Look for Experience: Seek out experienced pogo pin manufacturers with a proven track record.

Check their website for company history and expertise. - Assess Capabilities: Can they handle your required customization? What are their quality control processes? Do they offer OEM/ODM services?

- Gather Information: Read online reviews, look for case studies, or ask for references.

- Look for Experience: Seek out experienced pogo pin manufacturers with a proven track record.

-

Phase 3: Request Samples and Prototypes

- Narrow Your Choices: Select 2-3 promising suppliers.

- Get Samples: Request samples based on your defined specifications or for a custom prototype.

At CTP, we pride ourselves on our ability to deliver samples quickly, often within 15 days. - Evaluate Initial Quality: Even before testing, inspect the samples for build quality.

-

Phase 4: Rigorous Testing and Evaluation

- Real-World Testing: Test the magnetic pogo pin connector samples in your actual application or a simulated environment that mimics it.

- Verify Parameters: Check all critical parameters against your requirements.

-

Example Test Plan:

Parameter Test Method Expected Result / Pass Criteria Current Capacity Apply Max Rated Current No overheating, stable connection Mating Cycles Automated Mating/Unmating Meets specified cycle life (e.g., 50,000) Waterproofing (IPX7) Submerge in water (1m, 30min) No water ingress into critical areas Magnetic Force Pull test Within specified force range Contact Resistance Measure before/after life cycle Stays below max allowed mOhms

-

Phase 5: Final Selection and Partnership with Your Pogo Pin Manufacturer

- Make Your Choice: Select the pogo pin connector supplier that best meets all your technical requirements, quality standards, and budget.

- Discuss Logistics: Finalize terms for mass production, lead times, delivery schedules, and after-sales support. This is where a strong partnership truly begins.

By following these detailed steps, you can confidently navigate the selection process.

A thorough approach ensures the chosen magnetic pogo pin connector perfectly aligns with your project’s demands, leading to long-term success.

Why is Partnering with the Right Magnetic Pogo Pin Manufacturer So Crucial?

Worried about inconsistent quality or a lack of support for your project?

Choosing a subpar manufacturer for your magnetic pogo pin connectors can lead to significant project delays, failures, and ultimately, higher costs.

Partnering with the right magnetic pogo pin connector manufacturer is crucial for consistent product quality and reliability.

Such a manufacturer provides advanced customization, ensures stringent quality control, and offers dedicated support throughout the project lifecycle.

This collaboration minimizes delays and reduces overall costs.

Beyond simply supplying components, an effective manufacturing partner offers invaluable expertise.

They contribute to project success through robust quality systems and a deep understanding of application-specific needs.

This holistic approach helps navigate complex challenges

Beyond the Component: The Value of a Good Manufacturer

I’ve seen projects soar and others stumble, often hinging on the chosen manufacturing partner.

A top pogo pin manufacturer brings much more than just the physical parts.

- Deep Expertise and Innovation: Experienced magnetic pogo pin manufacturers possess material, design, and manufacturing process expertise, anticipating issues and offering innovative solutions.

- Unwavering Commitment to Quality: Seek manufacturers with robust quality systems and certifications.

Rigorous testing ensures each connector meets specifications, minimizing failures. - Tailored Customization Capabilities: Excellent suppliers offer OEM/ODM services, custom-designing connectors to fit your product’s unique shape and electrical needs.

- Reliable Support and Communication: A good magnetic pogo pin Supply partner provides responsive customer service and proactive communication, including timely after-sales support throughout the product’s lifecycle.

In essence, selecting a manufacturing partner goes beyond component supply.

It’s about securing a collaborative relationship that offers expert guidance, ensures product integrity, and streamlines your path to market success.

How to Choose the Perfect Magnetic Pogo Pin Connector?

Navigating the array of magnetic pogo pin connector options can be challenging.

Seeking partners who offer expert consultation, comprehensive custom design, rapid prototyping, and rigorous quality assurance will guide your selection effectively.

Choosing the right magnetic pogo pin connector involves expert consultation to define needs precisely.

Comprehensive custom design services ensure solutions fit unique specifications, while rapid prototyping validates designs efficiently.

Rigorous quality assurance then guarantees connector performance and long-term reliability.

Ultimately, the aim is to find a partner who understands your project’s unique demands.

This collaborative approach ensures the chosen magnetic pogo pin connector aligns perfectly with your product’s requirements.

This is key to successful integration and performance.

Your Approach to Connectivity Partnerships

When embarking on a new project, consider those who embrace a partnership approach.

The goal is to find providers who offer solutions, not just components.

Look for those with established facilities and experienced teams dedicated to serving a global market.

-

Consultative Guidance from Experts:

A crucial first step is thorough listening.

Providers should strive to understand your project, its challenges, and your goals.

Technical research and development teams can then provide tailored recommendations.

Personal engagement from key personnel can ensure that unique needs for magnetic pogo pin connectors are fully understood and met. -

Customization and Prototyping Excellence:

Excellence in OEM, ODM, and customized services for magnetic pogo pin connectors is vital.

A straightforward custom process typically involves:- You provide your product requirements and ideas.

- Clarification of all requirement details.

- Provision of a customized solution and design.

- A quotation provided after scheme confirmation.

- Deposit for sample making (with typical sample delivery around 15 days).

- Sample confirmation.

- An advance deposit for bulk goods (with typical bulk delivery around 15-20 days).

- Final payment upon completion of bulk goods.

This ability to deliver samples quickly helps you iterate faster, accelerating your development cycle.

-

Quality You Can Trust from a Leading Connector Provider:

Quality is paramount. Look for suppliers who implement robust management systems and strict quality control.

The use of high-quality imported materials is a strong indicator, as is compliance with numerous international standards like CE, TUV, RoHS 2.0, and REACH.

Certifications such as ISO9001, IATF16949, ISO14001, and ISO45001 demonstrate a commitment to quality.

High-precision inspection equipment further ensures every magnetic pogo pin connector is flawless. -

A One-Stop Solution for Your Magnetic Pogo Pin Needs:

From initial design and prototyping to timely mass production and delivery, a comprehensive, one-stop solution is highly beneficial.

Professional after-sales service ensures continued support throughout your product’s lifecycle.

Many successful collaborations with well-known brands highlight the capability to deliver exceptional high-current magnetic connection products and precise solutions.

Conclusion

Choosing the right magnetic pogo pin connector is vital for your project’s success.

Consider all factors carefully and partner with an experienced, reliable manufacturer like CTP for optimal results and innovative solutions.

Ready to find the perfect connector?

Contact us at CTP today!

My email is steven@magneticpogo.com.