Are you struggling with unreliable connections in compact PCB designs?

Traditional connectors often falter in high-density applications, causing frustrating performance issues.

Exploring alternative solutions can significantly enhance reliability.

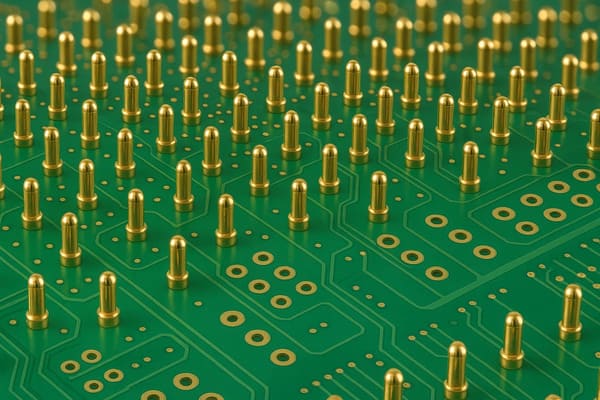

Pogo pins enhance reliability in high-density PCB connections by providing durable, spring-loaded contacts.

Their design ensures consistent pressure, maintaining stable electrical pathways despite vibrations or misalignment.

This leads to improved signal integrity and mechanical stability, crucial for compact electronic devices.

In today’s world of shrinking electronics, every millimeter counts.

Struggling with conventional connectors causing intermittent contact and failures?

Pogo pins from trusted pogo pin suppliers revolutionize compact designs.

The Challenge of High-Density PCB Connections: Why Is It So Tough?

Feeling the squeeze with your PCB designs? You’re not alone.

The demand for smaller, more powerful devices means high-density PCBs are becoming the norm.

High-density PCB connections are challenging due to miniaturization and complex signal routing.

Space constraints limit component size and placement, while maintaining signal integrity becomes difficult amidst increased crosstalk and impedance issues.

Additionally, thermal management and manufacturing precision are critical hurdles.

Miniaturization Demands and Connector Limitations

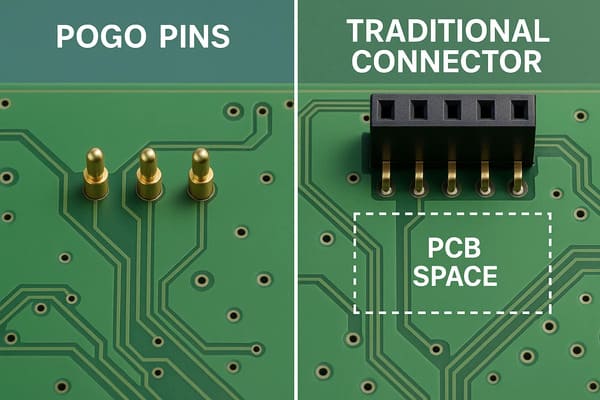

- Space Constraints: Traditional connectors, with their bulky housings and often larger pitches, consume valuable PCB real estate.

This makes it incredibly challenging to achieve the desired density.

I remember a client working on a new wearable device who was struggling to fit a standard board-to-board connector; switching to our custom magnetic pogo pin solution freed up critical space. - Assembly Complexity: Aligning and soldering traditional connectors in tight spaces can be a nightmare.

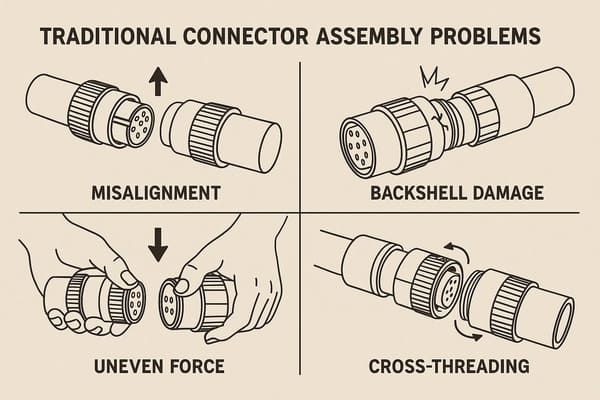

Misalignment is common, leading to rework and potential damage.

The precision required often slows down production lines. - Durability Concerns: Many traditional connectors are not designed for a high number of mating cycles.

In applications where modules are frequently connected and disconnected (like charging ports or swappable components), they can wear out quickly, leading to unreliable connections. - Signal Integrity Issues: As signal speeds increase, maintaining signal integrity becomes paramount.

Traditional connectors can introduce issues like impedance mismatches and crosstalk, especially in dense configurations, which can corrupt data and degrade performance.

This is a common pain point we hear from pogo pin buyers.

The following table summarizes some key limitations:

| Feature | Traditional Connectors in High-Density | Pogo Pin Solutions (from a reliable pogo pin manufacturer) |

|---|---|---|

| Space Efficiency | Often bulky, larger footprint | Compact, ideal for miniaturization |

| Assembly | Can be complex, requires precision | Simpler, SMT compatible, tolerant to misalignment |

| Durability (Cycles) | Variable, often lower | High mating cycles (e.g., 30,000 to 100,000+) |

| Signal Integrity | Prone to issues at high speeds | Good, with options for controlled impedance |

Navigating the complexities of high-density PCBs demands innovative connector solutions.

Overcoming these challenges ensures superior performance and reliability in ever-shrinking electronic designs.

Prioritizing robust and space-efficient connections is key.

What Are Pogo Pins? A Quick Refresher for High-Density Applications

You’ve likely encountered spring-loaded connectors.

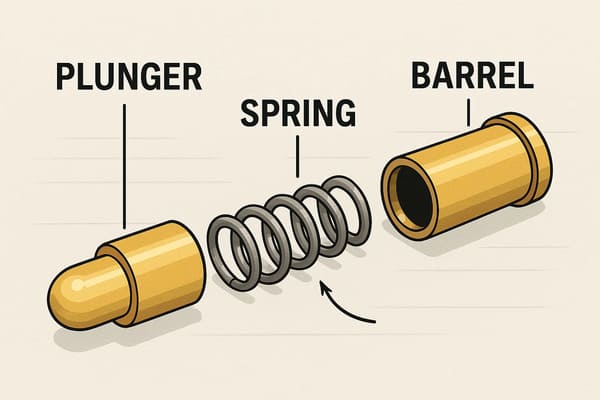

Each comprises a plunger, barrel, and internal spring.

This allows retraction and extension, creating reliable electrical connections.

Consistent spring force against a mating surface, often with a wiping action, helps maintain clean contacts.

Pogo pins are spring-loaded electrical connectors, each composed of a plunger, barrel, and internal spring.

They establish reliable connections by maintaining a constant contact force against a mating surface.

This design, often incorporating a wiping action, ensures robust electrical pathways.

Their compact nature makes them ideal for high-density electronic assemblies.

For this discussion on high-density PCBs, the key takeaway is that their compact nature, inherent durability, and ability to compensate for minor misalignments give them a significant edge over many traditional connectors, as we’ll explore next.

How Do Pogo Pins Enhance Reliability in High-Density PCBs?

Worried about connection failures in your compact devices?

Pogo pins, especially those from a reliable pogo pin supplier, offer a significant upgrade in reliability.

Pogo pins enhance reliability in high-density PCBs through their robust contact mechanism.

Consistent spring force maintains a stable connection, while a wiping action cleans the contact surface.

Their design offers durability, high mating cycle life, and resistance to shock and vibration, ensuring robust performance in demanding applications.

1. Superior Contact Mechanism

- Consistent Spring Force: The internal spring is engineered to provide a specific, consistent force throughout its working travel.

This constant pressure ensures that the plunger maintains reliable electrical contact with the mating pad, even if there are slight variations in the Z-axis (height).

This is a key differentiator from connectors that rely solely on friction or a fixed mating depth. - Wiping Action for Clean Contacts: As mentioned earlier, when a pogo pin compresses, the plunger typically rotates or slides slightly against the contact pad.

This wiping action is crucial for long-term reliability.

It helps to break through any oxide layers or contaminants that might build up on the contact surfaces over time, maintaining a low-resistance connection.

This self-cleaning aspect is particularly beneficial in environments where dust or mild corrosion might be a concern. - Tolerance Compensation: PCBs and assembled components are never perfectly flat or perfectly aligned due to manufacturing tolerances.

Pogo pins excel here because the spring allows each pin to individually adjust its height.

This means they can compensate for uneven surfaces, slight misalignments between mating parts, and manufacturing variances in component heights, ensuring all contacts are properly made.

This is a significant advantage that many leading pogo pin connector manufacturers highlight.

2. Impressive Durability and Cycle Life

- High Mating Cycles: Unlike some traditional connectors that can wear out after a few hundred or thousand cycles, pogo pins are often designed for tens of thousands, or even up to a million, mating cycles.

This makes them ideal for applications like charging ports, battery contacts in swappable battery systems, test fixtures, and modular components that are regularly connected and disconnected. - Robust Construction and Material Choices: Reputable pogo pin manufacturers use high-quality materials.

Barrels and plungers are typically precision-machined from brass or beryllium copper, chosen for their mechanical strength and conductivity.

Springs are made from materials like stainless steel or music wire.

Crucially, gold plating is commonly applied to the plunger and barrel.

Gold offers excellent corrosion resistance and very low contact resistance, ensuring the connection remains reliable over time and through many cycles.

3. Unwavering Shock and Vibration Resistance

- Spring-Loaded Resilience: The spring-loaded design of pogo pins inherently provides shock and vibration resistance.

The spring constantly pushes the plunger against its mating contact, so even if the device is jolted or vibrates, the connection tends to remain stable.

This is a stark contrast to some rigid connectors that can momentarily lose contact or even become dislodged under such conditions.

This feature is vital for portable electronics, automotive applications, and industrial equipment – key markets for magnetic pogo pin connectors.

Consider this comparison:

| Feature | Pogo Pins (from innovative pogo pin manufacturers) | Some Traditional Connectors |

|---|---|---|

| Contact Force Stability | Consistent due to spring | Can vary with wear/alignment |

| Mating Cycles | Very High (e.g., 30k – 1M+) | Lower to Moderate |

| Shock/Vibration | Excellent resistance | Can be susceptible to disconnects |

| Self-Cleaning | Yes, via wiping action | Typically No |

In summary, the inherent design of these connectors—with their self-adjusting, spring-loaded mechanism—provides critical advantages.

They offer robust, long-lasting electrical connections.

This makes them a superior choice for complex, high-performance electronic devices where reliability is paramount.

How Do Pogo Pins Boost Performance in High-Density PCBs?

Need to shrink your design without sacrificing electrical performance?

Pogo pins, especially the advanced magnetic pogo pin variants, are your allies.

Pogo pins boost PCB performance through their space efficiency, excellent electrical characteristics like low contact resistance and good signal integrity, ease of assembly, and remarkable design flexibility.

This makes them ideal for modern, compact electronics.

1. Remarkable Space Efficiency and Miniaturization

- Compact Footprint: Individual pogo pins have a very small diameter and can be placed very close to each other, allowing for a much higher connection density on the PCB compared to many traditional connectors.

This is crucial when every square millimeter counts. - Enabling Thinner Designs: Because pogo pins can connect directly to pads on a mating PCB or component without bulky housings, they contribute to overall thinner product profiles.

This is a significant advantage for wearables, smartphones, and other sleek devices.

2. Excellent Electrical Performance

- Low Contact Resistance: High-quality pogo pins, especially those with gold plating from a reliable pogo pin manufacturer, exhibit very low contact resistance (often in the range of 10-50 milliohms).

This minimizes power loss, reduces heat generation (critical in dense assemblies), and ensures signal integrity. - Good Signal Integrity: For high-speed data transmission, signal integrity is paramount.

Pogo pins can be designed and arranged to support controlled impedance applications.

Their short signal path length also contributes to reduced inductance and capacitance compared to some longer, more complex traditional connectors, which is beneficial for high-frequency signals.

Many specialized pogo pin suppliers offer designs optimized for RF or high-speed data. - Current Carrying Capacity: While individual standard pogo pins might have current ratings from 1-3 Amps, specialized high-current pogo pins are available that can handle significantly more (e.g., 5A, 10A, or even higher).

This versatility makes them suitable for both signal and power transmission.

3. Streamlined Assembly and Rework

- SMT Compatibility: Most pogo pins are designed for Surface Mount Technology (SMT), allowing them to be easily integrated into standard automated PCB assembly lines.

This reduces manual labor and assembly costs. - Reduced Alignment Precision: The inherent compliance of the spring-loaded plunger means that pogo pins are more forgiving of minor misalignments during assembly compared to rigid connectors that require precise mating.

This can improve manufacturing yields and reduce rework. - Simplified Repair and Modularity: Because pogo pins create a pressure-based connection, modules or components connected via pogo pins can often be easily removed and replaced without desoldering.

This simplifies repair and supports modular product designs, a feature highly valued by many pogo pin buyers.

4. Unmatched Flexibility and Versatility

- Customizable Designs: A customizable pogo pin manufacturer can tailor pogo pins to specific needs.

This includes variations in length, spring force, plunger tip style (e.g., flat, pointed, cupped, chisel), and materials.

This allows engineers to optimize the connector for their unique application. - Wide Range of Applications: This flexibility makes pogo pins suitable for a vast array of uses:

- Battery Contacts: Ubiquitous in phones, laptops, and portable devices.

- Docking Stations: For laptops, tablets, and handheld scanners.

- Modular Designs: Allowing different functional blocks to be easily connected.

- Test Points and Fixtures: For PCB testing and programming.

- Board-to-Board Connections: In compact multi-board systems.

- Magnetic Pogo Pin Connectors: Combining pogo pin reliability with the ease of magnetic alignment, perfect for charging cables and quick-connect systems.

The performance benefits are clear, making pogo pins and magnetic pogo pin connectors a powerful choice for innovative designs.

| Performance Aspect | Pogo Pins (from leading pogo pin suppliers) | Traditional Connector Challenges |

|---|---|---|

| Miniaturization | Excellent, small footprint | Can be bulky |

| Low Contact Resistance | Typically 10-50 mΩ | Can be higher, prone to increase |

| Signal Integrity | Good, short path, controlled Z options | Can introduce noise/loss |

| Assembly Ease | SMT compatible, tolerant | May require precise manual alignment |

| Customization | Highly customizable | Often standard, less flexible |

Ultimately, the versatile nature of these components—from their compact footprint to their robust electrical properties and adaptability—empowers engineers.

They can create high-performing, reliable, and space-efficient electronic devices.

This makes them an invaluable asset in modern product development.

What Key Considerations Should I Keep in Mind for Implementing Pogo Pins?

Ready to use pogo pins in your next project?

Thinking ahead during the design phase can save you headaches later.

When implementing pogo pins, key considerations include selecting the appropriate pin type for the application and optimizing PCB pad design.

Evaluating environmental factors like temperature and vibration is crucial.

Additionally, performing a thorough cost-benefit analysis ensures long-term suitability and success.

1. Design Phase Best Practices: Laying the Groundwork

- Choosing the Right Pogo Pin:

- Current Rating: Ensure the pin can handle the required current without overheating.

High-current pogo pins are available for power applications. - Cycle Life: Match the pin’s rated cycle life to the expected usage of your product.

A test fixture will need a much higher cycle life than a rarely disconnected internal module. - Working Travel & Force: Select a pin with appropriate working travel for your mechanical tolerances and a spring force that ensures good contact without overstressing components.

- Environment: Consider if you need features like sealing for moisture or dust protection, or specific materials for corrosive environments.

- Current Rating: Ensure the pin can handle the required current without overheating.

- Optimizing PCB Pad Design:

- Pad Material & Finish: Gold-plated pads (ENIG, Hard Gold) are generally recommended for mating with gold-plated pogo pin plungers to ensure low contact resistance and prevent fretting corrosion.

- Pad Size & Shape: The pad should be large enough to accommodate the plunger tip and any potential misalignment.

For wiping action, a slightly larger pad can be beneficial. - Pad Flatness (Coplanarity): Ensure the target contact surfaces are as flat as possible to promote even contact across multiple pins.

- Ensuring Proper Compression and Alignment:

- Recommended Working Height: Pogo pin manufacturers specify an optimal compression range (working height).

Operating the pin within this range ensures reliable contact and longevity.

Over-compression can damage the pin or reduce its life, while under-compression can lead to intermittent contact. - Mechanical Guidance: For arrays of pogo pins or in applications with blind mating, consider incorporating guide pins or features in the housing to assist with alignment.

This is especially important for high-density pogo pin connector arrays.

- Recommended Working Height: Pogo pin manufacturers specify an optimal compression range (working height).

2. Critical Environmental Factors

- Temperature: Pogo pins have an operating temperature range specified by the manufacturer.

Extreme temperatures can affect spring properties or material integrity. Select pins rated for your expected thermal environment. - Humidity and Moisture: In humid environments, corrosion can be a concern, especially if dissimilar metals are in contact.

Gold plating helps, but for very wet conditions, sealed pogo pins or connectors with IP ratings (like IP67 magnetic pogo pin connectors) might be necessary. - Contamination (Dust, Debris, Chemicals): While the wiping action helps, excessive contamination can still cause issues.

In dirty environments, consider protective measures like shrouds, seals, or regular cleaning cycles if feasible.

Some specialized pogo pin designs offer enhanced resistance to contamination.

3. Realistic Cost-Benefit Analysis

- Initial Cost: Compare the price of the pogo pins or pin connectors themselves.

- Assembly Cost: Factor in potential savings from easier SMT assembly and reduced manual labor or rework.

- Reliability & Warranty Costs: The higher reliability of pogo pins can lead to fewer field failures, reducing warranty claims and improving customer satisfaction.

This is a long-term saving that premium pogo pin manufacturers always emphasize. - Performance Gains: Consider the value of enabled features like miniaturization, improved signal integrity, or enhanced user experience (e.g., with magnetic pogo pin connectors for charging).

These can provide a competitive advantage. - Total Cost of Ownership (TCO): Often, when all factors are considered, the TCO for a pogo pin solution can be lower, especially for high-performance or high-reliability applications.

By carefully addressing these design, environmental, and economic factors, developers can successfully integrate these components.

This ensures robust performance and reliability in diverse electronic applications.

Thoughtful planning leads to optimized outcomes.

Conclusion

Pogo pins offer a compelling solution for improving reliability and performance in high-density PCBs.

Their unique design overcomes many limitations of traditional connectors.

For more information or to discuss your specific needs for pogo pins or magnetic pogo pin connectors, visit our website or contact us directly.

We are a global pogo pin supplier ready to assist you.