Ever wondered how your sleek smartphone crams so much tech into a tiny frame?

Custom Pogo Pins are the unsung heroes.

These small connectors solve big problems in electronics design, pushing the limits of what’s possible in compact devices.

Custom Pogo Pins are spring-loaded connectors designed for electrical connections in tight spaces.

They allow efficient power and signal transfer in miniaturized electronics.

Their compact size and customizable features make them perfect for modern devices.

From smartphones to medical devices, these connectors support innovation by enabling smaller, smarter designs with reliable performance.

Curious about how these tiny components transform tech?

Let’s explore their role and why they matter for the future.

What Are Pogo Pins and Why Choose Custom Pogo Pin Connectors?

Have you ever thought about what keeps electronic devices connected in such small spaces?

Pogo Pins are the answer, and customizing them takes things to the next level for specific needs.

Pogo pins are spring-loaded electrical connectors providing dependable contact within electronic devices.

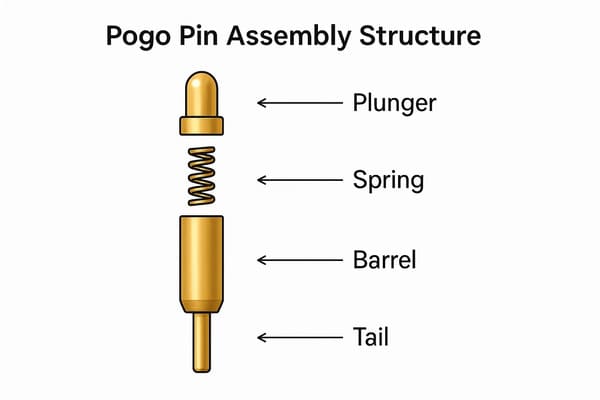

They comprise a plunger, barrel, and spring, accommodating slight misalignments.

Custom pogo pin connectors are chosen for unique design requirements, such as specific shapes or electrical properties, which are essential for specialized applications across various industries.

Want to know why customization is a game-changer?

Stick around to see the difference it makes.

Exploring the Basics of Custom Pogo Pin Connectors

- Tailored Fit: Custom Pogo Pins match exact device dimensions, reducing wasted space.

This precision allows designers to create slimmer, more compact products without sacrificing functionality.

Working with an innovative Pogo Pin supplier ensures a perfect fit every time. - Specialized Performance: They handle unique electrical loads, perfect for high-demand applications.

Whether it’s high current or specific voltage needs, these pins adapt seamlessly.

This makes them ideal for cutting-edge projects in consumer electronics. - Environment Resistance: Custom materials and plating options withstand tough conditions like heat or moisture.

This durability is critical for devices used in harsh settings, such as automotive or industrial tools.

A trusted Magnetic Pogo Pin manufacturer can recommend the best options. - Innovation Enablement: They allow designers to push boundaries in compact electronics.

With custom shapes and configurations, new ideas come to life easily.

Partnering with a precision Pogo Pin connector supplier opens up endless possibilities.

Here’s a quick comparison to clarify the value of working with an innovative Pogo Pin supplier:

| Aspect | Custom Pogo Pins | Standard Connectors |

|---|---|---|

| Size Adaptation | Tailored to fit tight spaces | Often bulky and fixed in size |

| Electrical Specs | Adjusted for specific current/voltage | Limited to generic ratings |

| Durability | Built for unique environmental challenges | May fail under harsh conditions |

| Design Flexibility | Shapes and configurations as needed | Restricted to preset designs |

Choosing custom pogo pins helps optimize device performance and longevity.

They provide reliable connections, supporting advanced designs in diverse applications.

This adaptability is key for future electronic innovations.

What Advantages Do Custom Pogo Pins Offer for Miniaturization?

Are you struggling to fit powerful tech into smaller designs?

Custom Pogo Pins solves this by offering unmatched benefits for shrinking electronics without losing performance.

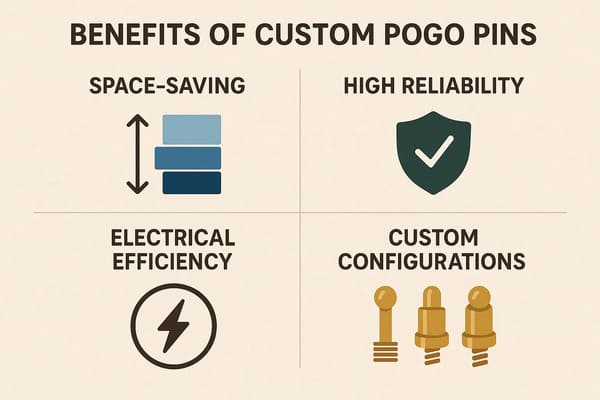

Custom pogo pins support miniaturization through their compact footprint, seamlessly integrating into tight spaces.

They enable the creation of thinner and lighter devices, such as wearables and medical instruments.

Their spring-loaded design ensures robust electrical connections while significantly conserving space, making them crucial for compact, efficient, and reliable electronics.

Ready to see how these benefits play out?

Let’s break down their impact.

Unpacking the Power of Custom Magnetic Pogo Pin Connectors

- Tiny Footprint: Fits into cramped layouts, supporting ultra-slim devices.

This small size is key for modern electronics like wearables or IoT gadgets.

It helps designers achieve sleek profiles without compromise. - Strong Durability: Resists wear from repeated use and tough environments.

The spring-loaded design absorbs shocks, extending the life of connections.

This reliability suits automotive and industrial applications perfectly. - Efficient Power: Handles high current with minimal signal loss.

Low contact resistance ensures smooth power and data transfer in small packages.

A durable Spring Loaded Pin supplier can tailor this for specific needs. - Flexible Options: Custom shapes and materials meet any design need.

From unique configurations to special plating, they adapt to project specs.

Partnering with a versatile Pogo Pin connector manufacturer ensures success.

Here’s how they stand out in key areas:

| Feature | Benefit | Application Example |

|---|---|---|

| Space-Saving | Reduces device thickness | Smartwatches, Tablets |

| High Reliability | Withstands shocks and vibrations | Automotive Systems |

| Electrical Efficiency | Low resistance for better performance | Medical Sensors |

| Custom Configurations | Matches unique project specs | IoT Modules |

Custom pogo pins are vital for modern electronics, offering tailored solutions for diverse design challenges.

They support miniaturization, enhance durability, and optimize electrical performance.

These specialized connectors empower innovations across various industries.

Where Are Custom Pogo Pins Applied in Modern Industries?

Wondering where these small connectors make a big difference?

Custom Pogo Pins are key players across various sectors, driving innovation in compact electronics.

Custom Pogo Pins power connections in wearables like smartwatches, medical devices such as sensors, and consumer electronics including smartphones.

They also serve automotive systems for electric vehicles, industrial tools like robotics, and IoT gadgets.

Their adaptability ensures reliable performance in diverse, space-constrained applications.

Curious about specific uses?

Let’s dive into their broad impact.

Real-World Uses of Custom Spring Loaded Pin Connectors

- Wearable Tech: Enables charging and data in fitness trackers and AR headsets.

These connectors fit into small spaces without adding bulk.

They ensure reliable performance for daily use. - Medical Tools: Supports miniaturized diagnostics and implantable devices.

Precision is critical here, and Pogo Pins deliver secure connections.

Working with a specialized Magnetic Pogo Pin supplier guarantees accuracy. - Consumer Devices: Fits into smartphones and smart home gadgets.

Their compact design supports sleek, modern looks.

They also handle frequent use without failing. - Automotive Uses: Powers ADAS and electric vehicle components.

These pins resist vibration, ensuring steady connections on the road.

A reliable Pogo Pin manufacturer can customize for harsh conditions. - Industrial Needs: Connects sensors and robots in automation.

Quick mating saves time during assembly or maintenance.

Their durability suits heavy-duty environments well. - IoT Applications: Drives efficiency in compact sensors and modules.

Small size and strong performance are vital for smart tech.

A global Spring Loaded Pin connector supplier can scale solutions.

Here’s a snapshot of their reach:

| Industry | Use Case | Key Benefit |

|---|---|---|

| Wearables | Smartwatches, Fitness Trackers | Compact and reliable connections |

| Medical | Sensors, Diagnostic Tools | Precision in small spaces |

| Consumer Electronics | Smartphones, Laptops | Supports sleek designs |

| Automotive | EV Charging, Infotainment | Durability under vibration |

| Industrial | Robotics, Test Probes | Quick and stable mating |

| IoT | Smart Sensors, Tags | Efficiency in tiny modules |

Custom pogo pins are vital for modern electronics, offering tailored solutions for diverse design challenges.

They support miniaturization, enhance durability, and optimize electrical performance.

These specialized connectors empower innovations across various industries.

How to Design Custom Pogo Pins for Optimal Performance?

Facing challenges in creating connectors for specific needs?

Designing custom Pogo Pins involves key factors to ensure they perform well in unique electronics.

Designing custom Pogo Pins requires attention to electrical needs like current and voltage.

Mechanical aspects such as spring force and travel distance matter too.

Consider environmental conditions like temperature or humidity.

Materials, plating, and mounting options balance cost and function, ensuring connectors fit specialized applications perfectly.

Custom pogo pins are widely adopted across modern industries due to their versatility.

They facilitate miniaturization and ensure robust connections in challenging environments.

These tailored solutions are essential for the ongoing evolution of compact and high-performance electronic devices.

Key Factors in Crafting Custom Pogo Pin Solutions

- Electrical Fit: Match current and voltage to avoid signal loss.

This ensures efficient power and data transfer in any device.

It’s a must for high-performance electronics. - Mechanical Strength: Set spring force for long-term use.

Proper travel distance supports repeated mating without wear.

This design focus extends the connector lifespan significantly. - Environment Prep: Choose materials for heat or moisture resistance.

This protects pins in tough conditions like outdoor or industrial settings.

A customizable Spring Loaded Pin manufacturer helps pick the right options. - Mounting Style: Select SMT or hybrid for easy assembly.

This choice speeds up production and cuts labor costs.

It also ensures a snug fit in tight layouts. - Cost Balance: Weigh budget against needed features.

High performance doesn’t always mean high cost with the right design.

Working with an advanced Pogo Pin connector supplier finds the sweet spot.

Here’s a guide to design priorities:

| Design Aspect | Consideration | Impact on Performance |

|---|---|---|

| Electrical Specs | Current, Voltage, Impedance | Ensures signal and power efficiency |

| Mechanical Needs | Spring Force, Travel Distance | Affects durability and mating cycles |

| Environmental Factors | Temperature, Humidity, Corrosion | Maintains reliability in tough settings |

| Material Choices | Gold, Nickel, Palladium Plating | Improves conductivity and lifespan |

| Mounting Options | SMT, Through-Hole, Hybrid | Simplifies device assembly |

Designing these connectors requires a holistic approach, balancing electrical, mechanical, and environmental factors.

Careful material selection and mounting considerations are also vital.

This ensures optimal performance and longevity for specialized electronic applications.

What’s the Future of Electronics with Custom Pogo Pin Connectors?

Are you curious how electronics will keep getting smaller and smarter?

Custom Pogo Pins are set to lead the way with new possibilities for design and function.

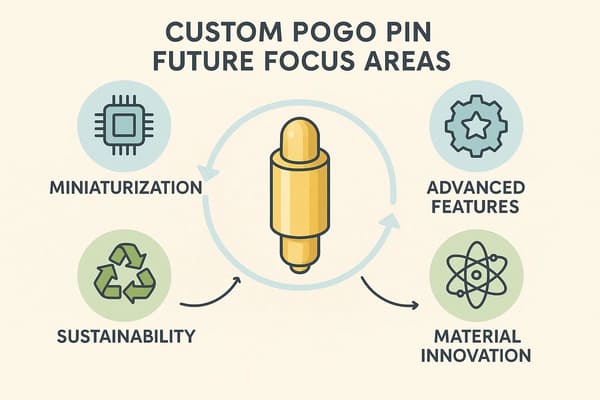

Custom Pogo Pins will drive further miniaturization in electronics, supporting smaller, integrated designs.

They’ll enable higher data rates and power in future devices.

Modular setups with these connectors may aid repairability, cutting electronic waste.

Emerging trends point to smarter, more efficient Pogo Pin technology ahead.

Interested in what’s next?

Let’s check out their evolving role.

Shaping Tomorrow with Advanced Magnetic Pogo Pins

- Smaller Designs: Enables micro-devices with full functionality.

Future electronics will shrink even more with these connectors.

They’ll fit into spaces we can’t imagine today. - Better Features: Supports high-speed data and power needs.

Next-gen devices will demand more from tiny components.

Pogo Pins will rise to meet these challenges. - Sustainable Options: Modular connections for easier fixes.

This approach reduces waste by simplifying repairs or upgrades.

It’s a win for both users and the environment. - Tech Advances: New materials and designs for efficiency.

Innovations like self-cleaning pins could cut maintenance needs.

Working with a top Spring Loaded Pin supplier keeps you ahead.

Here’s a look at future focus areas:

| Trend | Impact | Potential Use |

|---|---|---|

| Miniaturization | Smaller, integrated electronics | Micro IoT sensors |

| Advanced Features | Higher data and power capacity | Next-gen wearables |

| Sustainability | Easier repairs, less waste | Consumer device upgrades |

| Material Innovation | Smarter, durable options | Harsh environment tools |

These specialized connectors are poised to reshape electronics.

They will enable ever-smaller devices with enhanced capabilities for data and power.

Moreover, their evolving design will support greater sustainability through improved repairability.

Conclusion and Call to Action

Custom Pogo Pins are shaping the future of electronics with compact, reliable solutions.

At CTP, we’re committed to innovation.

Explore our offerings at home page or reach out via contact page.

Let’s build the next big thing together!