Faulty connectors often lead to frustrating product failures and dissatisfied customers.

Magnetic pogo pin connectors offer a secure, intuitive, and durable solution for many modern electronic applications.

Magnetic pogo pins are spring-loaded connectors that utilize magnets for precise alignment and secure mating.

They ensure reliable power and data transfer, proving especially valuable in consumer electronics, medical devices, automotive systems, and industrial equipment where ease of use, durability, and safety are paramount.

These innovative connectors offer more than just convenience, they bring significant technical advantages to the table.

Let’s dive deeper into why magnetic pogo pin connectors, also known as spring loaded pins with magnets, might be the perfect choice for your next design project and what factors to consider when selecting them.

Why Choose Magnetic Pogo Pin Connectors for Your Design?

Need connections that are quick, reliable, and foolproof?

Traditional connectors can be fiddly, prone to misalignment, and wear out over time.

High-quality magnetic pogo pins simplify the connection process, enhancing user experience and extending product lifespan significantly.

Magnetic pogo pin connectors are chosen for design due to their inherent ease of use and self-aligning capability.

Their design minimizes friction, enhancing durability.

They also offer improved safety through a breakaway feature, making them ideal for various applications requiring reliable, convenient connections.

As discussed, magnetic pogo pins address common issues with traditional connectors by offering better alignment and longevity.

Now, delving into their key advantages provides valuable insights for optimizing designs in electronics and beyond.

Key Advantages of Magnetic Spring Loaded Pins

Magnetic pogo pin connectors, a specialty of reliable pogo pin suppliers offer distinct benefits:

- Effortless Connection: Magnets automatically guide the connector halves into perfect alignment, enabling quick, easy, and often "blind" mating.

This is incredibly beneficial for consumer devices like smartwatches, audio gear, or medical equipment where users demand simplicity and reliability.

Think of the satisfying click of a well-designed magnetic connection – that’s the user experience we aim for. - Superior Durability: The magnetic alignment minimizes the scraping and friction common with traditional push-and-click connectors during mating and unmating cycles.

This significantly reduces mechanical wear on the contact points and housing. - Enhanced Safety: In applications where cables might be subject to sudden tension (like charging cables in busy environments or connections on portable medical devices), the magnetic interface allows for a clean breakaway.

This prevents damage to the device’s port or the cable itself if accidentally snagged or tripped over, a crucial safety feature. - Design Freedom: The compact nature of magnetic pogo pin connectors allows engineers to create sleeker, lower-profile product designs. Furthermore, they can be readily integrated into sealed assemblies, achieving high IP ratings for water and dust resistance, making them suitable for rugged industrial environments or outdoor electronic devices.

How to Select the Right Magnetic Pogo Pin Supplier?

Worried about inconsistent quality and unreliable delivery from component suppliers?

Choosing an inadequate partner often results in costly project delays, product redesigns, and potentially faulty end products.

Selecting a trustworthy magnetic pogo pin supplier is absolutely critical for success.

Selecting a magnetic pogo pin supplier involves evaluating several key factors.

Assess their industry experience, alongside relevant quality management certifications.

Look for demonstrated customization capabilities and sufficient scalable production capacity.

Finally, responsive customer support is crucial for effective collaboration and problem-solving throughout the partnership.

When sourcing pogo pins, prioritize suppliers that deliver consistent quality and support seamless project flow from start to finish.

Researching a supplier’s background and track record is key to ensuring reliable performance and informed decision-making.

Evaluating Potential Pogo Pin Manufacturers

When you’re looking for a long-term partner, like a premier magnetic pogo pin manufacturer, consider these vital factors:

- Certifications and Compliance: Ensure the Magnetic Pogo Pin Connectors supplier holds relevant quality certifications.

ISO 9001 is fundamental, while IATF 16949 is crucial for automotive projects like Paul’s.

Look for environmental compliance (ISO 14001) and product-specific standards (RoHS, REACH, CE).

These certifications aren’t just paperwork, they reflect a commitment to rigorous processes and quality control, essential for accessing markets like Europe and North America. - Technical Expertise & R&D Strength: When assessing suppliers, consider if they maintain a strong in-house engineering team.

They should effectively handle complex requirements and deliver innovative solutions.

A robust R&D capability ensures the development of precise, customized magnetic pogo pin connectors. - Manufacturing Capabilities & Quality Control: Assess their physical infrastructure.

What’s the pogo pin factory size? How many employees (~200+)?

What kind of production and inspection equipment do they use?

Do they implement robust quality systems like 7S management?

These factors indicate their ability to handle volume production while maintaining strict quality standards. - Lead Times, Communication & Service: In today’s fast-paced market, quick turnaround times are often essential.

Ask about sample lead times and pogo pin bulk production timelines.

Equally important is clear communication and reliable after-sales support.

A responsive partner makes the entire process smoother.

What Customization Options Are Available for Magnetic Pogo Pins?

Finding that standard, off-the-shelf connectors just don’t meet the unique demands of your product design?

Relying on generic parts can stifle innovation and compromise optimal performance.

Custom magnetic pogo pin connectors provide solutions precisely tailored to your specific application requirements.

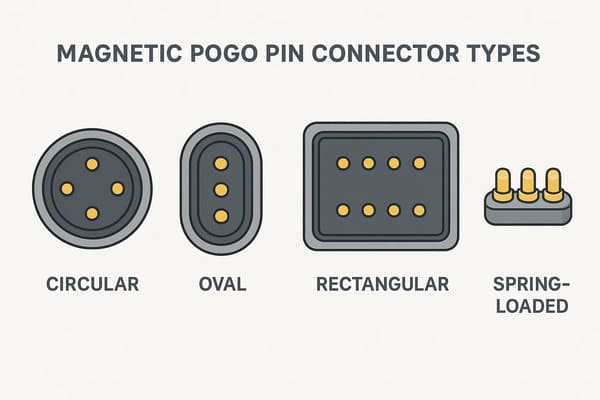

Magnetic pogo pin customization is extensive.

Options include adjusting pin count, arrangement, and overall height.

Current capacity, spring force, and specific materials or plating can be specified.

Environmental sealing levels, such as IP ratings, and connector housing shape are also customizable.

When evaluating magenetic spring loaded pin connector options, look for suppliers that provide extensive customization services to adapt solutions precisely to your project’s needs.

Tailoring Magnetic Pogo Pin Connectors to Your Needs

When working with specialized magnetic spring loaded pin connectors, it’s essential to recognize that they often require tailored components.

A structured custom development approach can effectively address specific project requirements:

| Customization Stage | Description |

|---|---|

| 1. Requirements Definition | We start by thoroughly discussing your project’s specific needs: electrical parameters (current rating, voltage, signal type), mechanical constraints (size, shape, mating cycles, force), and environmental factors (temperature range, required IP rating for water/dust). |

| 2. Design & Prototyping | Our experienced R&D team translates your requirements into detailed connector designs using CAD tools. We then leverage our capabilities for rapid prototyping, typically delivering custom samples within 15 days for your evaluation and testing. |

| 3. Material Selection | Choosing the right materials is critical for performance and longevity. This includes selecting base materials (e.g., brass, copper alloys for pins), housing plastics (considering temperature and strength), spring materials, magnet types, and appropriate plating (e.g., gold for conductivity and corrosion resistance). |

| 4. Testing & Validation | Before mass production, custom magnetic pogo pin connectors undergo rigorous testing. This includes electrical testing (continuity, resistance, current capacity), mechanical testing (mating cycles, spring force, dimensions), and environmental testing (temperature, humidity, salt spray) to ensure they meet all specifications. |

A comprehensive one-stop solution for magnetic pogo pin connectors can streamline the entire process, from initial concept to design, prototyping, testing, mass production, and delivery.

Drawing from extensive experience, it addresses challenging applications in consumer electronics, automotive systems, medical devices, aerospace, and industrial IoT.

Conclusion

Magnetic pogo pin connectors offer a compelling blend of reliability, ease of use, and durability.

Partnering with an experienced, technologically advanced, and customizable pogo pin supplier like CTP ensures you get high-quality components tailored to your specific needs.

Ready to enhance your product with superior connectivity? Contact us.