Are you facing unreliable connections in compact designs?

It’s a headache when signal loss or failures hit critical systems.

Traditional connectors often fall short under stress.

Let’s dive into how pogo pin technology offers a robust fix with cutting-edge engineering.

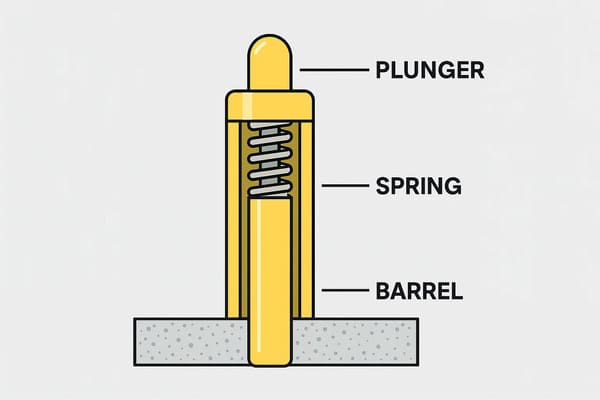

The pogo pin principle relies on spring-loaded contacts to establish stable electrical connections.

This design allows for reliable current transfer while accommodating variations in mating surfaces.

Precision engineering and material science ensure durability, enabling these pins to withstand repeated compression cycles and environmental stresses.

Stay tuned for a deeper look.

I’ll uncover key insights into the pogo pin market that can transform your approach to reliable connectivity.

What Drives the Physics of Pogo Pin Contact?

Ever puzzled over why some connectors fail under pressure?

The secret lies in micro-level interactions.

Pogo pin design leverages fundamental physics to ensure consistent, low-resistance connections for high-stakes uses.

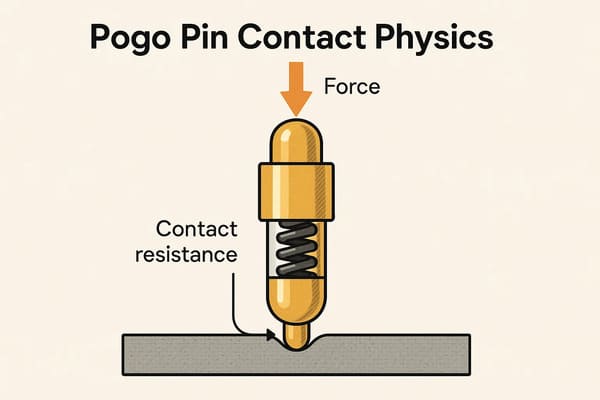

The physics of pogo pin contact is driven by a controlled spring force.

This force maintains consistent pressure between microscopic touchpoints, ensuring stable electrical paths.

This design minimizes contact resistance even with slight misalignments, optimizing current flow in compact electronic assemblies.

Let’s zoom in further.

These details can reshape your understanding of spring loaded pin performance in real-world conditions.

Understanding Contact Resistance at the Micro-Level

Tiny details dictate big outcomes in electrical contacts.

Unseen interactions at the surface level impact reliability.

A durable pogo pin factory often refines these aspects for superior results.

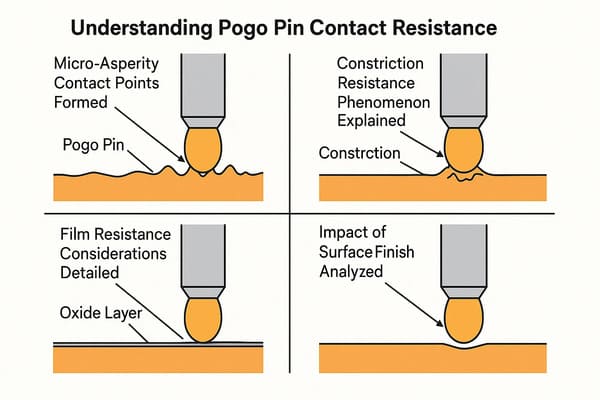

- Micro-Asperity Contact Points Formed: Real contact happens at microscopic peaks on surfaces.

Despite apparent smoothness, only these asperities touch.

This limited area drives resistance, but optimized spring probes enhance contact through precise pressure distribution. - Constriction Resistance Phenomenon Explained: Current funnels through tiny contact spots, creating resistance bottlenecks.

This restricts flow and raises heat.

Industry expertise suggests designing tips to spread these points, reducing constriction for better efficiency. - Film Resistance Considerations Detailed: Surface oxides or contaminants form resistive layers.

These films disrupt current if not addressed.

Based on field insights, self-wiping actions in these connectors break through barriers for cleaner connections. - Impact of Surface Finish Analyzed: Smoothness and plating affect contact quality.

Gold finishes cut resistance and resist tarnish.

Experience shows that premium surface treatments, often prioritized by expert makers, extend performance life significantly.

These micro-factors shape overall success.

Let’s explore another critical piece—how spring mechanics ensure lasting contact in spring loaded pin connectors.

Spring Mechanics and Force-Deflection Dynamics

Beyond surfaces, internal dynamics play a huge role.

Springs are the heart of reliable pressure.

An innovative pogo pin wholesaler can guide selections for optimal force in varied designs.

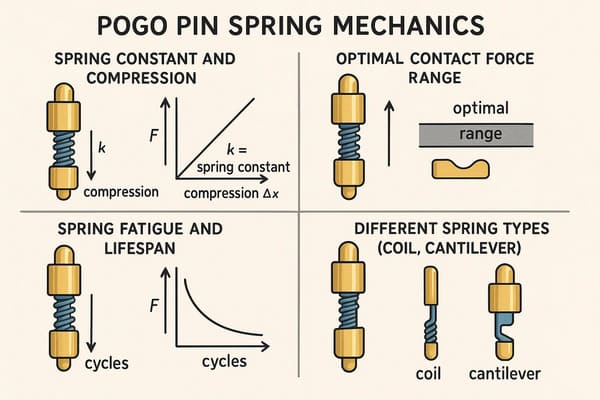

- Spring Constant and Compression: This measures force per unit of deflection.

Proper constants ensure stable contact without excess stress.

Industry know-how recommends matching this to application needs for balanced compression over time. - Optimal Contact Force Range: Too little force risks disconnection; too much force damages parts.

A defined range maintains ideal pressure.

Field experience points to testing within specs for consistent, damage-free operation. - Spring Fatigue and Lifespan: Repeated cycles can weaken springs over time.

High-quality materials delay fatigue onset.

Practical tips suggest choosing designs rated for your expected usage to avoid early wear. - Different Spring Types (Coil, Cantilever): Coil springs offer linear force, while cantilever options suit unique geometries.

Each fits specific needs. Based on expertise, selecting the right type ensures fit and function in custom setups.

These mechanics underpin durability.

Let’s move into how electrical principles elevate pogo pin connector performance for complex systems.

How Do Advanced Electrical Principles Enhance Pogo Pins?

Designing for modern electronics demands flawless power and data flow.

Small inefficiencies can spiral into major issues.

Let’s unpack the electrical engineering behind spring-loaded contacts.

Advanced electrical principles enhance pogo pins through optimized current paths and signal clarity.

Their design minimizes heat buildup, crucial for high-power applications.

This structure also preserves high-frequency data integrity, ensuring reliable performance even under intense electrical demands.

Why is this critical for your project?

Stick with me to explore deeper insights into spring probe capabilities for cutting-edge applications.

Current Path Optimization and Heat Dissipation

Power delivery must be efficient to avoid losses.

Poor paths create risks like overheating.

A specialized pogo pin manufacturer refines these elements for robust outcomes.

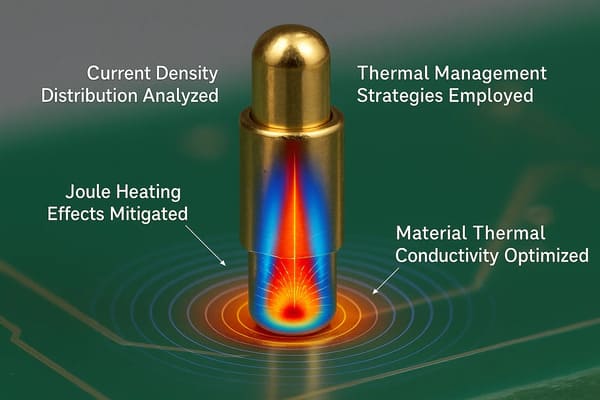

- Current Density Distribution Analyzed: Uneven flow across contact areas causes hot spots.

Balanced designs spread current uniformly.

Industry insights recommend larger contact zones or high-conductivity materials to stabilize density. - Thermal Management Strategies Employed: Heat sinks or airflow can aid cooling.

Pin materials also dissipate energy.

Practical advice focuses on pairing designs with environments to keep temperatures in check. - Joule Heating Effects Mitigated: Resistance turns current into wasted heat.

Short paths and low-resistance plating curb this.

Based on field data, minimizing contact resistance is key to curbing thermal rise. - Material Thermal Conductivity Optimized: Copper cores or brass bodies shed heat fast.

Conductivity keeps components cool under load.

Expertise suggests prioritizing such materials for high-current spring loaded pin connectors.

Managing power flow is just one piece.

Let’s look at how these connectors maintain data integrity under demanding conditions.

Signal Integrity and High-Frequency Performance

Data speed matters as much as power in modern systems. Distortions can ruin performance.

Designing connections for clean signal transmission, especially with components like pogo pin connectors, is crucial for optimal function.

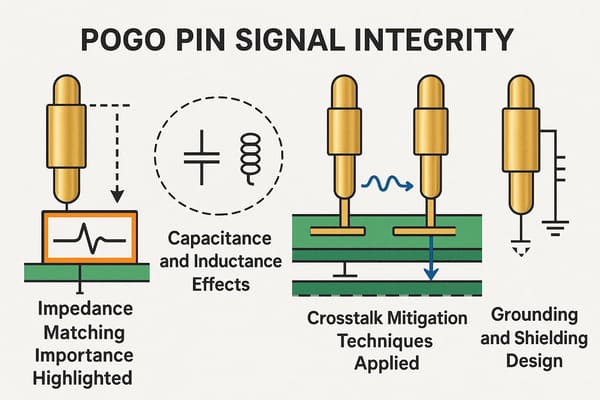

- Impedance Matching Importance Highlighted: Mismatched impedance reflects signals, causing errors.

Consistent paths prevent this.

Industry know-how stresses aligning connector impedance with system needs for smooth data flow. - Capacitance and Inductance Effects: Parasitic effects distort high-frequency signals over distance.

Compact designs minimize these.

Practical input suggests short pin lengths to reduce interference risks. - Crosstalk Mitigation Techniques Applied: Signal bleed between adjacent pins disrupts clarity.

Strategic spacing cuts interference.

Experience that shows careful layout planning keeps channels isolated for clean output. - Grounding and Shielding Design: Proper grounds drain noise, while shields block external fields.

Both protect signal paths.

Field insights recommend integrated grounding in spring probes for sensitive applications.

Electrical finesse drives next-gen tech.

Let’s shift to how manufacturing precision shapes spring loaded pin connector reliability at every level.

What’s Behind Precision Manufacturing of Pogo Pins?

Crafting tiny connectors demands exacting standards.

Even minor flaws can undo performance.

Let’s dive into the manufacturing and material science powering pogo pin solutions.

Precision manufacturing of pogo pins involves adhering to tight tolerances and applying advanced coatings.

These processes ensure smooth operation, minimizing friction and wear.

Careful material selection further contributes to longevity, enabling components to withstand rigorous, repeated use across various applications.

Curious about the details?

I’ll break down the craftsmanship that makes spring loaded pin connectors stand out in tough environments.

The Role of Plunger Geometry and Barrel Tolerances

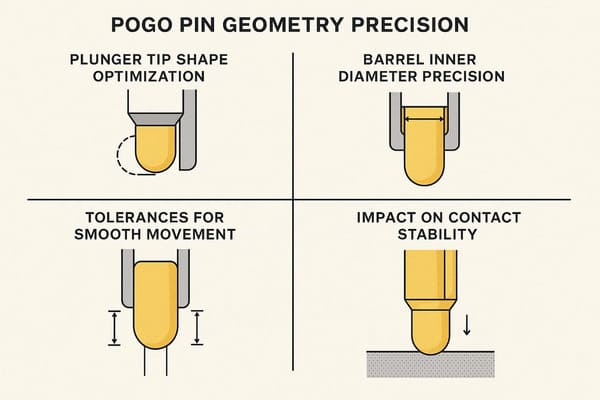

Plunger geometry and barrel tolerances are critical for pogo pin performance.

Precise tip shapes optimize contact, while exact barrel diameters ensure smooth, consistent movement.

These careful considerations prevent wear and maintain stable connections in micro-connectors.

- Plunger Tip Shape Optimization: Rounded or pointed tips affect the contact area and pressure.

Each suit has different pads.

Industry expertise advises matching shapes to mating surfaces for ideal engagement. - Barrel Inner Diameter Precision: Tight barrels risk binding; loose ones lose force.

Exact sizing ensures smooth slides.

Based on field know-how, micron-level accuracy keeps motion fluid and reliable. - Tolerances for Smooth Movement: Clearances must allow travel without wobble.

Precision machining hits this balance.

Practical tips suggest rigorous testing to confirm consistent plunger action over cycles. - Impact on Contact Stability: Geometry affects how the force applies to pads.

Stable designs resist tipping. Experience shows that well-tuned dimensions, a focus of many makers, uphold connection quality.

These details build a strong foundation.

Let’s explore how surface science adds another layer of durability to spring probes.

Advanced Plating and Surface Treatment Sciences

Advanced plating and surface treatments enhance pogo pin durability, resisting wear and corrosion.

Multi-layer systems optimize conductivity and ensure long-term reliability.

- Multi-Layer Plating Systems: Nickel undercoats with gold tops balance cost and conductivity.

Layers resist wear.

Industry insights recommend tailored stacks for specific corrosion or contact needs. - Adhesion and Wear Resistance: Poorly bonded plating flakes off under stress.

Strong adhesion endures cycles.

Based on practical data, advanced bonding techniques extend surface life. - Tribology of Contact Surfaces: Friction science guides low-wear designs.

Lubricity cuts abrasion at touchpoints.

Field experience suggests optimizing this for high-cycle pogo pin applications. - Corrosion Prevention Mechanisms: Plating seals out oxidants and moisture.

Alloy choices bolster defense.

Expertise points to environmental testing as key to validating protective layers.

Surface mastery boosts resilience.

Let’s examine how these components stand up to harsh surroundings with spring loaded pin connector design.

How Do Pogo Pins Engineer for Environmental Resilience?

Harsh conditions test every connector’s limits.

Failures here can halt operations.

Let’s uncover how spring-loaded designs are built to endure tough environments.

Pogo pins achieve environmental resilience through sealed designs and robust material selection.

They incorporate features like specialized plating to resist corrosion and durable springs to withstand mechanical shock and vibration.

Engineering focuses on preventing ingress of contaminants and maintaining stable contact under extreme temperatures and humidity, ensuring reliable performance in challenging conditions.

Why does resilience matter so much?

I’ll share key mechanisms that ensure spring probe reliability, no matter the setting.

Mitigating Environmental Degradation Mechanisms

Nature’s elements can erode even strong designs.

Protective strategies counter these risks.

A solutions-oriented pogo pin supplier prioritizes building for lasting function.

- Fretting Corrosion Prevention: Micro-motions at contacts grind away material, forming oxides.

Stable force limits this wear.

Industry know-how suggests anti-fretting coatings or designs to maintain steady pressure. - Humidity and Condensation Effects: Moisture breeds rust and shorts in electronics.

Sealed pogo pins block ingress.

Based on field insights, IP-rated options or protective barriers excel in damp zones. - Vibration and Shock Absorption: Shakes can loosen rigid connectors, breaking circuits.

Springs dampen impact. Practical advice emphasizes internal resilience as key to uptime in dynamic settings. - Temperature Cycling Impact: Heat-cool loops stress materials, cracking joints.

Thermal-rated pins endure swings.

Experience recommends cycle testing to confirm performance across temperature extremes.

These safeguards ensure consistent output.

Such engineering equips spring loaded pin connectors for the toughest B2B demands.

Conclusion

To wrap up, pogo pin technology blends physics, materials, and precision to deliver unmatched reliability.

These principles empower your designs with enduring connectivity.

Learn more on our homepage or connect through our contact page.

We’re ready to support your pogo pin needs.