Ever wonder why some electronic devices last longer than others, or why a connection suddenly fails?

Often, the unsung hero or culprit is a tiny component you rarely see: the pogo pin.

These critical connectors enable everything from charging your phone to ensuring complex medical devices work flawlessly.

Understanding the materials used in pogo pins is crucial for their performance and longevity.

Common materials include brass for the pin body, which offers good machinability, and premium gold plating for the contact surface, enhancing conductivity and corrosion resistance.

The choice of these materials directly impacts the pogo pin’s durability and ability to maintain reliable connections in various applications.

Now, stick with me.

In this post, I’ll break down the common materials used by leading pogo pin suppliers and show you why they matter for your business.

What is a Pogo Pin and Why Do Materials Matter?

Have you ever struggled with a device that just won’t charge or connect?

Chances are, a pogo pin is at the heart of the issue.

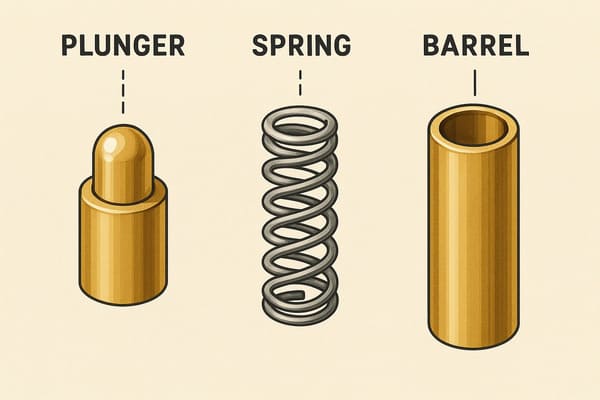

These small spring-loaded pin connectors create temporary electrical contacts in everything from smartphones to medical equipment.

A pogo pin is a spring-loaded connector that establishes temporary electrical contacts.

Materials are crucial as they determine conductivity, durability, and corrosion resistance.

Proper material selection ensures stable signal flow and extended lifespan, whereas inferior materials can cause issues like oxidation and premature wear, impacting overall device reliability.

Let’s dive into this further.

I’ll walk you through the specific materials used in pogo pin production and why they’re crucial for your needs.

Core Body Materials: How Do They Shape Pogo Pin Performance?

The core body material forms the backbone of a pogo pin connector, significantly influencing its performance.

Understanding these materials is key to ensuring device reliability and functionality.

This section explores the primary material choices and their respective characteristics.

Pogo pin performance is shaped by core body materials like brass, beryllium copper (BeCu), and phosphor bronze.

Brass is economical but prone to oxidation.

BeCu provides high strength, suitable for demanding applications, while phosphor bronze offers a balance of wear resistance, ideal for general use.

Each material’s properties directly impact the pin’s durability and electrical performance.

Exploring Core Materials for Spring Loaded Pins

- Brass: This material is widely used due to its affordability and good conductivity.

It’s easy to machine, making it a go-to for many innovative pogo pin manufacturers.

However, it’s prone to tarnishing and has lower wear resistance.

I’ve seen it excel in low-cost consumer gadgets but fail in humid conditions. - Beryllium Copper (BeCu): Known for excellent spring properties and high strength, BeCu is a favorite for premium spring-loaded pin manufacturers.

It’s perfect for industrial and medical applications requiring durability.

The downside? It’s pricier and poses manufacturing safety concerns due to beryllium dust. - Phosphor Bronze: This offers a balance between cost and performance.

It has better corrosion resistance than brass and good strength.

It’s often used by versatile magnetic pogo pin connector suppliers for mid-range products.

However, its conductivity isn’t as high as copper.

Here’s a structured look at how these materials compare for your needs as a potential pogo pin buyer:

| Material | Conductivity | Durability | Cost | Best Application |

|---|---|---|---|---|

| Brass | Good | Low (Oxidizes) | Low | Consumer Electronics |

| Beryllium Copper | High | High (Fatigue Resistant) | High | Medical, Industrial |

| Phosphor Bronze | Moderate | Moderate (Wear Resistant) | Moderate | Mid-Range Connectors |

Choosing the right core body material is paramount for optimizing pogo pin performance.

Each material presents a unique set of trade-offs in conductivity, durability, and cost.

Carefully considering these factors ensures the selection aligns with the specific application’s demands, leading to reliable and long-lasting connections.

Plating Materials: Why Surface Matters for Pogo Pin Connectors?

The plating on a pogo pin’s surface is crucial for its protection and enhanced performance.

This surface treatment significantly influences the connector’s reliability and longevity.

Understanding the various plating options is essential for optimal device function.

Surface plating critically impacts pogo pin connectors by enhancing conductivity and corrosion resistance.

Gold provides superior performance for sensitive electronics.

Nickel acts as a durable base layer, while palladium-nickel offers a cost-effective alternative.

Silver delivers high conductivity but is prone to tarnishing, and tin presents a budget-friendly option.

Unpacking Plating Options for Magnetic Pogo Pins

- Nickel Plating: This is often an undercoat for other materials.

It’s hard, durable, and resistant to corrosion.

However, its contact resistance is higher than gold.

It’s a must-have layer in most designs from trusted spring-loaded pin connector suppliers. - Gold Plating: With unmatched conductivity and corrosion resistance, gold is the gold standard intended.

It’s ideal for aerospace and medical devices.

Hard gold lasts longer underwear, while soft gold suits low-friction needs.

The catch? It’s expensive. - Palladium-Nickel (PdNi): This offers good wear resistance and conductivity at a lower cost than gold.

It’s a rising choice among eco-friendly pogo pin connector manufacturers, though it may need a gold flash to prevent corrosion. - Silver Plating: It has the best conductivity among common metals but tarnishes easily.

It’s great for high-current uses if tarnishing isn’t an issue. - Tin Plating: This is a budget-friendly option.

It’s often used where cost matters more than longevity, though it wears out faster.

Here’s a quick comparison for clarity, tailored for buyers seeking a high-quality magnetic pogo pin supplier:

| Plating Material | Conductivity | Corrosion Resistance | Cost | Best Use Case |

|---|---|---|---|---|

| Nickel | Moderate | Good | Low | Undercoat, Industrial |

| Gold | Excellent | Excellent | High | Aerospace, Medical |

| Palladium-Nickel | Good | Good (with Gold Flash) | Moderate | Cost-Sensitive High-Performance |

| Silver | Excellent | Poor (Tarnishes) | Moderate | High-Current Applications |

| Tin | Moderate | Poor | Low | Budget Connectors |

For any pogo pin application, the right plating ensures superior electrical connection and critical resistance to corrosion and wear.

By meticulously matching the chosen surface plating to specific operational environments and current requirements, designers can guarantee the pogo pin’s reliable function and extended lifespan, maximizing overall device performance.

Spring Materials: How Do They Ensure Pogo Pin Longevity?

The longevity of a pogo pin largely depends on its internal spring.

The choice of spring material is critical for ensuring reliable performance over many cycles.

Understanding these materials is vital for designing durable and effective connectors.

Spring materials ensure pogo pin longevity through their inherent properties.

Stainless steel offers elasticity and corrosion resistance for standard uses.

Music wire, while economical, exhibits faster wear under stress.

Beryllium copper wire provides superior durability, making it ideal for demanding, high-stress applications and extended operational life.

Analyzing Spring Materials for Spring Loaded Pin Connectors

- Stainless Steel: This is the go-to choice for springs in pogo pin connectors.

It resists corrosion and maintains consistent force over thousands of cycles.

It’s a staple for reliable pogo pin connector suppliers across industries. - Music Wire: It offers high elasticity at a low cost.

However, it’s less durable under repeated stress.

It’s often used in less critical applications by budget-conscious manufacturers. - Beryllium Copper Wire: This provides top-tier durability and performance.

It’s perfect for demanding environments like aerospace, where failure isn’t an option.

It’s a premium pick for an advanced spring-loaded pin manufacturer.

Here’s a table to help you compare spring materials as a potential magnetic pogo pin buyer:

| Spring Material | Elasticity | Corrosion Resistance | Cost | Ideal Application |

|---|---|---|---|---|

| Stainless Steel | Good | High | Moderate | General Use, Consumer Goods |

| Music Wire | High | Low | Low | Low-Cost Applications |

| Beryllium Copper | Excellent | High | High | Aerospace, High-Stress Uses |

The right spring material is paramount for pogo pin performance. Each option—stainless steel, music wire, or beryllium copper—brings distinct advantages. Matching the material to the specific application ensures long-term reliability and functionality.

What Factors Influence Pogo Pin Material Selection?

Understanding the factors that influence material selection for a pogo pin connector is crucial.

The process involves aligning specific operational needs with material performance.

This thoughtful approach ensures the connector functions reliably within its intended application.

Pogo pin material selection is influenced by several key factors.

These include the application’s environment, such as temperature and humidity, alongside performance requirements like cycle life, current handling, and contact resistance.

Balancing cost with these technical specifications is also a primary consideration in determining the optimal material.

Key Considerations for Choosing Materials in Pogo Pin Manufacturing

- Application Requirements: A medical device needs high reliability, often requiring gold plating.

Consumer electronics might prioritize cost, using brass from a customizable pogo pin supplier. - Environmental Conditions: High humidity or heat demands corrosion-resistant materials like stainless steel or gold.

I’ve seen connectors fail in harsh settings when this is ignored. - Cycle Life and Durability: High-cycle uses, like in testing equipment, need BeCu for longevity.

A precision spring-loaded pin supplier can tailor to expected usage. - Current and Signal Needs: High current applications need materials like silver.

Signal integrity often demands low resistance, a focus for top magnetic pogo pin manufacturers. - Cost vs. Performance: Budget constraints might lead to brass or tin.

Premium projects justify gold.

It’s about value, not just price.

Here’s a quick guide for clarity, especially for B2B clients seeking a trusted pogo pin connector supplier:

| Factor | Impact on Material Choice | Example Need |

|---|---|---|

| Application | Defines reliability level needed | Medical = Gold, BeCu |

| Environment | Affects corrosion and wear resistance | Humidity = Stainless Steel |

| Cycle Life | Determines durability requirement | High Cycles = Beryllium Copper |

| Current/Signal | Influences conductivity needs | High Current = Silver Plating |

| Cost | Balances quality with budget | Low Budget = Brass, Tin |

Optimal pogo pin material selection hinges on evaluating functional demands, environmental conditions, and cost.

This strategic approach ensures the pogo pin connector delivers reliable performance, extended cycle life, and a long service life, crucial for successful application integration.

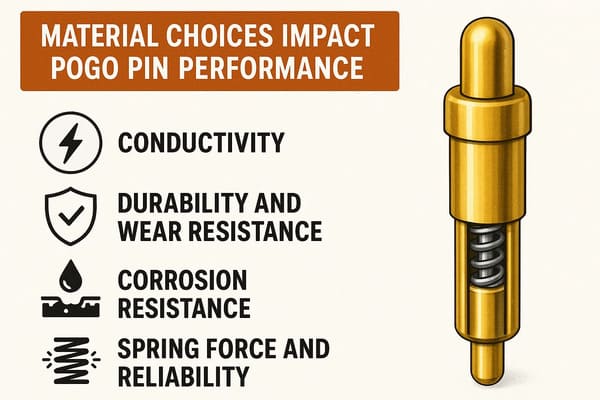

How Do Material Choices Impact Pogo Pin Performance?

When considering pogo pin connectors, material choices are paramount.

Aligning these selections with operational demands ensures dependable performance.

This careful approach helps guarantee the connector’s reliability in its specific use case.

Material selections critically influence pogo pin performance.

Conductivity, for instance, relies on materials like gold or copper for signal integrity.

Durability and wear resistance, often from BeCu or nickel, determine the pin’s lifespan.

Corrosion resistance, provided by gold or stainless steel, prevents failures in harsh environments.

Additionally, spring force, particularly with BeCu, ensures reliable contact.

Breaking Down Performance Factors for Magnetic Pogo Pin Connectors

- Conductivity: Gold and silver plating offer the best current flow. Copper in the body helps too.

Poor conductivity means signal loss- a disaster for data-driven applications. - Durability and Wear Resistance: BeCu and nickel extend a pin’s life under friction.

I’ve seen cheap materials wear out fast, costing clients in replacements. - Corrosion Resistance: Gold and stainless steel fight rust and tarnish.

This is vital in humid or salty environments, a key focus for a durable magnetic pogo pin supplier. - Spring Force and Reliability: BeCu springs keep contact steady over cycles.

Weak springs lead to intermittent connections and frustrating users.

Here’s a table to show how materials link to performance, useful for any magnetic pogo pin buyer:

| Performance Area | Key Material | Why It Matters |

|---|---|---|

| Conductivity | Gold, Silver, Copper | Ensures signal clarity and power flow |

| Durability | BeCu, Nickel | Extends lifespan under heavy use |

| Corrosion Resistance | Gold, Stainless Steel | Prevents failure in harsh conditions |

| Spring Force | BeCu, Stainless Steel | Maintains consistent, reliable contact |

Enhancing pogo pin performance hinges on informed material choices.

Each selection directly influences the connector’s functionality, durability, and resilience in various operational environments.

This strategic approach is key to achieving long-term reliability.

Conclusion and Call to Action

I hope this deep dive into pogo pin materials—from brass to gold plating—has shown you their importance.

Choosing the right material ensures your devices perform reliably.

Need tailored solutions?

At CTP, we’re a leading pogo pin supplier ready to help.

Visit our homepage or reach out via our contact page for expert support.