Struggling with unreliable connections or clumsy docking?

Choosing the right magnetic pogo pin isn’t just about magnets; key design details are vital for success.

Key design considerations for magnetic pogo pins include: material durability for longevity, electrical specifications like current rating, magnetic strength for proper alignment, environmental resistance (IP rating and temperature tolerance), plus customization options matching specific application requirements.

Prioritizing these factors ensures reliable connections in demanding conditions.

These factors ensure your connection is not only convenient but also robust and reliable for the long term.

Let’s dive deeper into each consideration to help you make an informed choice for your next project.

How Do Material Selection and Durability Impact Magnetic Pogo Pin Performance?

Worried about your connectors failing under repeated use or harsh conditions?

Inferior materials in pogo pins can lead to premature wear, corrosion, and ultimately, connection failure, impacting your product’s reliability.

Material composition fundamentally governs pogo pin durability and electrical performance.

Base metals (e.g., brass, beryllium copper) determine conductivity and mechanical resilience, while plating (gold, nickel) provides corrosion resistance and wear mitigation.

Proper material synergy extends operational lifespan by sustaining mechanical integrity and electrical stability in demanding environments.

Material selection critically determines long-term reliability in magnetic pogo pin connectors, particularly under demanding operational conditions.

Choosing appropriate compositions ensures sustained electrical performance and mechanical durability, significantly extending product lifespan while preventing connection failures in challenging environments.

Materials and Durability of Pogo Pin

The core components of a pogo pin – the plunger, barrel, and spring – each require specific material properties.

- Plunger & Barrel: Typically made from brass (good cost-performance) or beryllium copper (excellent spring properties and conductivity).

The choice depends on the balance between mechanical strength, electrical performance, and cost. - Spring: Usually stainless steel or music wire, selected for its elasticity and fatigue resistance to ensure consistent contact force over many cycles.

- Plating: This is crucial. Gold plating offers excellent conductivity and corrosion resistance, ideal for low-voltage signals and harsh environments.

Nickel plating provides durability and a good base layer.

Plating thickness matters; thicker gold plating (e.g., 3-50 microinches) generally means better durability and corrosion resistance.

Specialized material grades and plating customization become critical for high-cycle applications like 100,000+ mating operations.

Enhanced material durability and thicker protective finishes combat wear and chemical degradation, maintaining pogo pin functionality in extreme conditions.

What Electrical Specifications are Critical for Magnetic Pogo Pin Connectors?

Are you experiencing frustrating signal drops, data corruption, or even connector overheating?

Choosing magnetic pogo pins without considering the precise electrical requirements can seriously compromise device functionality and safety.

Critical electrical specifications for magnetic pogo pin connectors include: Current carrying capacity (amperage) – determines maximum continuous current without overheating.

Maximum voltage rating – ensures safe operation within insulation limits.

Contact resistance (milliohms) – critical for minimizing signal degradation in data transmission.

Proper parameter matching prevents connector overheating and maintains data integrity.

Understanding these electrical parameters is essential for any device, from low-power wearables to high-current charging systems.

Let’s break down why these specs matter.

Electrical Performance Needs of Magnetic Pogo Pin Connector

Selecting a magnetic pogo pin connector demands careful consideration of its electrical capabilities to ensure it performs reliably within your system.

- Current Rating: This is perhaps the most critical spec. It defines the maximum continuous current the pin can handle without overheating.

Mismatching this can lead to component failure or even fire hazards.

Applications vary widely – simple data signals might need less than 1A, while power charging pins, like those needed by clients such as Paul in the automotive sector, might require 5A, 10A, or even 15A+. - Contact Resistance: Lower is better. High resistance causes voltage drops and generates heat (I²R losses), especially problematic in high-current or sensitive signal applications.

Stable, low contact resistance (typically measured in milliohms) ensures efficient power transfer and clean signal transmission.

Material choice, plating, and spring force all influence this. - Voltage Rating: Specifies the maximum voltage the connector can safely insulate between adjacent pins or contacts.

Exceeding this can lead to arcing or short circuits.

| Specification | Importance | Typical Range/Consideration |

|---|---|---|

| Current Rating | Prevents overheating, ensures power delivery | <1A (Signal) to 15A+ (Power) |

| Contact Resistance | Minimizes voltage drop, heat, ensures signal quality | Low milliohms (e.g., <30mΩ) |

| Voltage Rating | Prevents electrical breakdown, ensures safety | Depends on pin pitch & insulation |

Targeted electrical configurations address specific technical challenges in demanding applications.

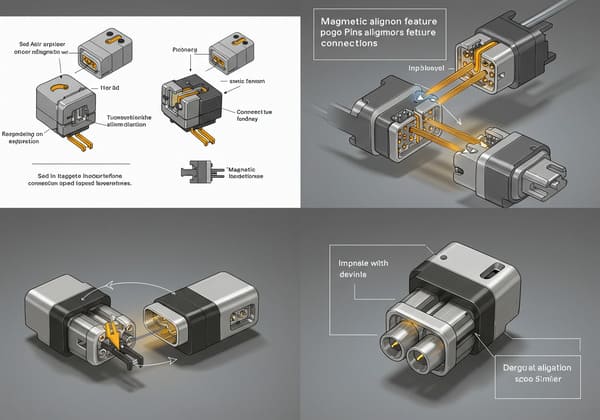

Why is Magnetic Force and Alignment Crucial for Magnetic Pogo Pins?

Ever get frustrated with magnetic connectors that barely hold on, detach unexpectedly, or require fiddling to align correctly?

Weak or poorly optimized magnetic force compromises the user experience and connection reliability.

Proper magnetic force and alignment ensure critical functions: securing retention against disconnections, enabling self-alignment to prevent pin damage, and maintaining reliable electrical contact.

These provide tactile confirmation of successful mating while eliminating manual positioning risks.

Ultimately, this guarantees resilient connections during movement or vibration.

The "magic" of magnetic connectors lies in this balance of holding force and alignment assistance.

It’s more than just adding a magnet; it’s about precision engineering.

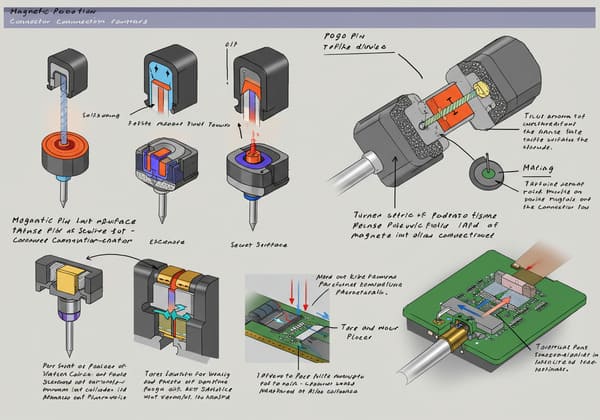

The Role of Magnetics

The magnetic system in a pogo pin connector is integral to its function and user satisfaction.

Getting it right involves several factors:

- Magnet Type and Strength: Neodymium magnets (NdFeB) are commonly used due to their high strength-to-size ratio.

The required force depends on the application: strong enough to hold securely against accidental bumps or movement, but not so strong that detachment is difficult.

This often involves careful calculation and prototyping. - Alignment Assistance: Magnets can be arranged (often with specific polarities N/S) to actively guide the two connector halves into the correct orientation.

This prevents users from forcing a connection incorrectly, which could damage the pogo pins or the mating surface.

This self-aligning feature is a major usability benefit. - Holding Force vs. Shear Force: Designers consider both the force needed to pull the connectors directly apart (holding force) and the force needed to slide them apart (shear force).

The design might prioritize resistance against one type of movement depending on how the device is typically handled. - Magnetic Shielding: In some sensitive applications, containing the magnetic field is important to avoid interference with other electronic components.

This might involve adding shielding materials or specific geometric design choices.

Careful magnetic circuit optimization balances secure retention with user-friendly engagement, ensuring pogo pins maintain consistent electrical contact throughout repeated mating cycles.

How Do Environmental Factors Influence Magnetic Pogo Pin Selection?

Have your connectors ever failed unexpectedly when exposed to moisture, dust, or extreme temperatures?

Environmental conditions can severely degrade connector performance and lifespan if not accounted for during the design phase.

Environmental factors critically influence magnetic pogo pin selection: temperature extremes (-40°C to +125°C operational ranges are common) dictate material choices, while IP67-rated sealing prevents water/dust ingress in harsh conditions.

Vibration-prone settings require spring-loaded contacts to maintain electrical integrity, and corrosive environments demand specialized plating.

Proper environmental matching prevents premature failure, extending connector lifespans.

A connector designed for a clean indoor office environment will likely fail quickly if used outdoors or in an industrial setting.

Matching the connector’s resilience to its environment is key.

Environmental Resilience of Magnetic Pogo Pin Connector

Designing for the operating environment ensures the magnetic pogo pin connector maintains its integrity and performance throughout the product’s life. Key factors include:

- Ingress Protection (IP Rating): This standard (e.g., IP67, IP68) defines the level of protection against solid particles (dust) and liquids (water).

Essential for wearables, outdoor equipment, medical devices, or anything exposed to spills or cleaning. Sealing often involves O-rings or specific housing designs. - Temperature Range: Magnetic Pogo Pin Connectors must operate reliably across the expected temperature extremes.

Standard ranges might be -20°C to +85°C, but automotive or industrial applications often require wider ranges (e.g., -40°C to +125°C).

High temperatures can affect spring force and plastic housing integrity. - Shock and Vibration: Critical for automotive, aerospace, and portable devices.

The magnetic pogo pin connector design must maintain contact integrity even when subjected to mechanical stress.

Spring force, locking mechanisms (though less common with pure magnetic types), and robust construction play a role. - Corrosion Resistance: Requires careful base material selection and robust plating—such as thicker gold layers—when facing humidity, salt spray, or chemical exposure.

Compliance with industry standards like RoHS and REACH further safeguards durability.

Rigorous testing protocols ensure magnetic pogo pin connectors meet demanding environmental specifications for reliable performance.

How Important is Customization and Integration Support from a Magnetic Pogo Pin Manufacturer?

Are you finding that standard, off-the-shelf magnetic connectors just don’t quite fit your product’s unique shape, electrical needs, or integration requirements?

Relying only on standard parts can stifle innovation and lead to compromises.

Customization support from a magnetic pogo pin manufacturer enables tailored solutions for exact dimensional specifications, specific electrical loads, and unique mating geometries.

This ensures seamless mechanical integration and reliable electrical connectivity in final products.

Such flexibility avoids design compromises caused by standardized connectors, optimizing device functionality.

Off-the-shelf works sometimes, but truly optimized designs often require a tailored approach. Working with a partner who offers customization is key.

The Value of Customization for Magnetic Pogo Pin connector

Partnering with a Customizable magnetic pogo pin manufacturer unlocks significant advantages, allowing you to move beyond standard offerings and achieve optimal product design.

Here’s how:

- Tailored Form Factor:

- Dimensions: Adjust pin length, diameter, pitch (distance between pins), and overall connector height to fit tight space constraints.

- Shape: Design custom housing shapes to match your product’s aesthetics or specific mounting requirements.

- Specific Electrical Needs:

- Define precise current ratings (low or high), contact resistance targets, or impedance control for high-frequency signals.

- Configure pin counts and layouts specific to your power and data requirements.

- Unique Mating & Features:

- Engineer specific magnetic forces and alignment features for your desired user experience.

- Incorporate features like integrated sealing (IP ratings), specific locking mechanisms (if needed alongside magnets), or unique material/plating combinations.

- Streamlined Integration: A customized connector designed with your specific PCB layout and assembly process in mind simplifies manufacturing and reduces potential integration issues.

This tailored approach ensures precise dimensional, electrical, and mechanical compatibility beyond standardized limitations, directly optimizing device functionality through seamless physical integration and reliable connectivity.

Conclusion

Selecting the right magnetic pogo pin involves carefully weighing material durability, electrical specs, magnetic design, environmental resilience, and the potential for customization.

Partnering with an experienced pogo pin manufacturer ensures success.