Struggling with magnetic Pogo Pin connector failure in wet or dusty conditions?

Unreliable connections can halt your critical operations and frustrate users.

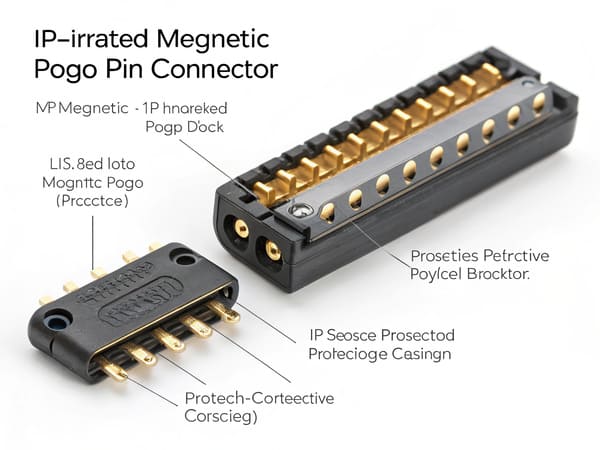

An IP (Ingress Protection) rating defines a magnetic pogo pin’s level of protection against solids and liquids.

A higher rating indicates better sealing against contaminants like dust and water.

This directly affects performance by ensuring stable electrical conductivity and operational reliability across different applications, preventing failures in harsh conditions.

Understanding IP ratings is essential, but how does this protection impact real-world performance for magnetic pogo pins?

Having delved into this field, it’s clear how vital this aspect is.

Let’s explore this further with practical insights.

Why is IP Rating Crucial for Magnetic Pogo Pins in Demanding Environments?

Facing connection issues in tough settings like industrial automation or outdoor devices?

Environmental factors can severely compromise the performance of any magnetic pogo pin connector.

An IP rating is crucial as it defines a magnetic pogo pin’s resistance to contaminants like dust and water.

This protection prevents ingress that can cause short circuits, corrosion, and signal degradation.

Consequently, it ensures consistent performance and operational reliability, which is vital for devices in demanding environments.

Diving Deeper into Environmental Protection for Magnetic Pogo Pins Connectors

Exploring the intricacies of environmental protection is vital when dealing with components such as magnetic pogo pin connectors.

The IP (Ingress Protection) rating rating") system is an international standard (IEC 60529) that classifies the degrees of protection provided by enclosures for electrical equipment.

The rating consists of two digits:

- First Digit: Protection against solid objects (ranging from 0 – no protection, to 6 – dust-tight).

- Second Digit: Protection against liquids (ranging from 0 – no protection, to 8 – continuous immersion, or even 9K for high-pressure jets).

Without an adequate IP rating matched to the operating environment, magnetic pogo pin connectors can suffer various failures:

- Corrosion: Moisture ingress reacts with metal contacts, increasing resistance or causing open circuits.

- Short Circuits: Conductive dust or water bridging contacts can cause immediate failure.

- Mechanical Jamming: Dust and debris can interfere with the spring mechanism of the pogo pin.

- Signal Degradation: Contamination can affect the integrity of data signals, especially in high-frequency applications.

For demanding sectors like automotive, medical, and industrial automation, reliability is crucial.

High-quality materials matter, but the right IP rating ensures a proper environmental seal.

Meeting strict standards like ISO, RoHS, and REACH is often essential for global clients.

How Do Different IP Ratings Impact Magnetic Pogo Pin Connector Design and Application?

Choosing the right connector seems complex?

Selecting the wrong IP rating for your magnetic pogo pin can lead to costly failures or unnecessary over-engineering.

Different IP ratings directly influence magnetic pogo pin connector design and application suitability.

Lower ratings, like IP54, are designed for controlled indoor settings with minimal exposure to contaminants.

Conversely, higher ratings such as IP67/IP68 require more robust sealing, making them essential for reliable performance in outdoor or industrial environments.

Matching Design and IP Rating to the Need

Achieving higher IP ratings for components like a magnetic pogo pin connector requires careful attention to design and manufacturing techniques.

To ensure durability and performance in challenging environments, several effective methods can be applied during the process.

- Sealing Rings/Gaskets: O-rings or flat gaskets made from materials like silicone are placed strategically to block ingress pathways, protecting critical parts from dust and moisture.

- In-Mold Molding: Overmolding the connector housing directly onto the cable or PCB assembly creates a seamless, integrated seal, enhancing environmental resistance.

- Potting/Pouring: Filling internal cavities with epoxy or polyurethane resin safeguards internal components from moisture and contaminants, ensuring long-term reliability.

- Material Selection: Choosing corrosion-resistant materials for pins (such as brass or beryllium copper with suitable plating) and durable, waterproof plastics for housings is essential for robust performance.

Here’s a simple comparison of common IP ratings and typical applications:

| IP Rating | Solid Protection (1st Digit) | Liquid Protection (2nd Digit) | Typical Application Environment |

|---|---|---|---|

| IP54 | Protected against dust (limited ingress) | Protected against water splashes | Indoor equipment, controlled environments |

| IP65 | Dust-tight | Protected against water jets | Outdoor equipment (sheltered), industrial washdown areas |

| IP67 | Dust-tight | Protected against immersion (up to 1m) | Wearables, portable devices, outdoor sensors |

| IP68 | Dust-tight | Protected against continuous immersion (beyond 1m) | Underwater devices, rugged electronics, medical devices |

Choosing the right IP rating is a delicate balance. Over-specifying, like opting for IP68 when IP54 is enough, raises costs unnecessarily. Under-specifying risks, early failure, and warranty concerns.

The key is to carefully assess the actual environmental needs for components like magnetic spring loaded pin connectors.

This ensures you select the optimal IP rating, striking a balance between durability and cost-efficiency.

What Industries Benefit Most from High IP-Rated Magnetic Pogo Pins?

Wondering where robust magnetic connectors make the biggest impact?

Standard connectors often fail in specialized, demanding fields where reliability is paramount.

High IP-rated magnetic pogo pins are essential in industries like automotive, medical, and industrial automation.

Consumer electronics, particularly wearables, also widely utilize them for enhanced durability.

Their robust sealing ensures reliable performance and operational continuity by preventing failures from dust or liquid exposure in demanding environments.

Key Applications Driving Demand

High IP ratings aren’t just a feature; they’re a critical requirement in several key markets, directly impacting the performance and longevity of magnetic pogo pin connectors:

- Consumer Electronics:

- Smartwatches & Fitness Trackers: Need water resistance for daily wear, sweat, and swimming.

- Rugged Tablets/Phones: Designed for outdoor or harsh work environments.

- Waterproof Speakers/Headphones: For use near pools or in the rain.

- Magnetic Chargers: IP-rated magnetic USB connectors enhance safety and durability, especially for portable devices.

- Medical Devices:

- Portable Monitoring/Diagnostic Tools: Must withstand cleaning, sterilization processes, and potential fluid exposure. Reliability is critical for patient safety.

- Automotive Electronics:

- EV Charging Connectors: Exposed to weather conditions.

- External Sensors (Cameras, Lidar): Need protection from rain, dust, and road grime.

- Engine Bay Components: Face high temperatures, fluids, and vibrations.

- Industrial Automation:

- Robotics & Machinery: Operate in environments with dust, oil, and water jets (washdown).

- Outdoor Sensors & Controls: Exposed to weather extremes year-round.

In critical fields, avoiding failure is essential.

A high IP rating ensures device longevity, user safety, and consistent performance for magnetic pogo pin connectors.

Exploring industry resources can offer valuable insights and guidance.

Conclusion

Choosing the correct IP rating for your magnetic pogo pin connector is vital.

It directly impacts reliability, safety, and product lifespan in its intended environment.

Need help finding the perfect fit? Contact us.