Experiencing unreliable device connections?

Spring-loaded connectors like pogo pins provide exceptional durability and stability for these demanding technical requirements, ensuring consistent performance even in challenging scenarios.

Pogo pins support high-current and high-frequency signal transmission through careful design. This involves selecting appropriate materials and plating for optimal conductivity.

Additionally, precise physical dimensions and a robust contact interface are crucial.

These elements, combined with impedance matching, ensure efficient and reliable signal performance for critical applications.

Understanding how these tiny yet powerful connectors achieve such impressive feats can be a game-changer for your product design.

To fully appreciate their capabilities, a quick recap of pogo pin fundamentals is helpful.

This will lay a solid foundation for exploring their advanced applications.

Pogo Pin Fundamentals: A Quick Recap for Better Understanding?

New to pogo pins or just need a quick refresher on these essential components?

Misunderstanding the basics can unfortunately lead to design flaws down the line.

Let’s briefly cover what pogo pins are.

Pogo pins, often called spring-loaded pins or spring-loaded pin connectors, are electromechanical connectors that utilize an internal spring mechanism.

This ensures consistent and reliable electrical contact between two surfaces, even when dealing with movement or vibrations.

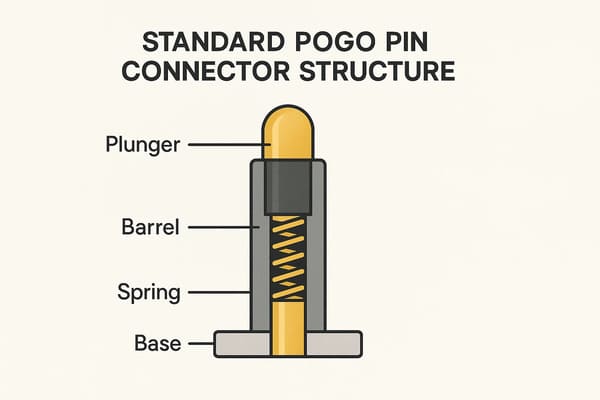

They primarily consist of a plunger, a barrel, and a spring.

Years of development have refined the design of these connectors.

For instance, in a wearable device where standard connectors struggled with constant motion, a well-designed spring-loaded pin solution proved highly effective.

These precision-engineered connectors operate like miniature spring-loaded pistons, ensuring dependable electrical connections through their plunger, tube, and spring components while maintaining consistent contact pressure.

- Plunger (or Pin Head): This is the crucial component that makes direct contact with the target surface.

Its shape—be it pointed for precision, flat for current, or round for durability—can be customized by a knowledgeable pogo pin manufacturer. - Barrel (or Pin Body): This cylindrical housing encases the spring and plunger, meticulously guiding the plunger’s axial movement.

- Spring: This component provides the necessary compressive force to maintain a stable and continuous electrical contact.

The true beauty of these parts lies in their synergy, creating a connection that’s both stable and resilient.

A reliable pogo pin manufacturer ensures each part is crafted with utmost precision.

| Component | Primary Function | Common Materials Used |

|---|---|---|

| Plunger | Establishes and maintains electrical contact | Brass, Beryllium Copper |

| Barrel | Houses plunger & spring, guides movement accurately | Brass, Phosphor Bronze |

| Spring | Provides consistent contact force for reliability | Stainless Steel, Music Wire |

Understanding these fundamental components is key to appreciating how pogo pins deliver reliable performance.

Their integrated design ensures consistent contact.

This foundational knowledge is essential for effective application in various devices.

How Are Pogo Pins Engineered for High Current Applications?

Need to power your demanding electronic devices reliably and safely?

Insufficient current capacity in connectors can, unfortunately, cause dangerous overheating or complete system failure.

Specialized pogo pins are meticulously designed for these high-current challenges.

Pogo pins engineered for high-current applications utilize highly conductive materials and robust plating.

They feature larger physical diameters and optimized contact interfaces to reduce resistance.

These design elements collectively minimize heat buildup, ensuring efficient and safe power delivery.

This meticulous engineering supports demanding electronic devices reliably.

Handling high current effectively presents a significant engineering challenge in connector design.

It’s not merely about increasing a pin’s size; instead, it involves a detailed and meticulous engineering process.

-

Material Selection: An experienced pogo pin manufacturer often select highly conductive materials such as beryllium copper or tellurium copper for the plunger and barrel.

These materials exhibit lower electrical resistance, which is absolutely crucial for minimizing heat generation (I²R losses) under load. -

Plating Quality and Thickness: Gold plating is a common choice due to its excellent conductivity and superior corrosion resistance.

For high current pogo pins, a thicker plating layer (e.g., 30-50 microinches) ensures a durable and low-resistance contact path over many cycles. -

Physical Dimensions (Diameter): Generally, a pogo pin with a larger diameter provides more surface area for current to flow.

This reduces current density and overall resistance.

A trusted supplier consistently advises clients on the optimal diameter based on their specific current requirements and space constraints. -

Contact Interface Design: The precise design of the plunger tip and the mating surface is critical for performance.

A larger, flatter contact area can typically handle more current more effectively than a pointed one.

In some demanding scenarios, multiple pogo pins are used in parallel to distribute the current load. -

Effective Heat Dissipation: For applications involving very high currents, the overall design must carefully consider how heat will be dissipated from the pogo pin connector.

This prevents overheating and potential damage to the device.

This might involve specific PCB layout considerations or even integrated heat sinks in extreme cases.

These elements are precisely engineered for demanding applications, ensuring consistent and reliable performance.

Thoughtful design and material selection are paramount for achieving optimal functionality in high-current scenarios.

What Goes into Designing Pogo Pins for High-Frequency Signal Transmission?

Facing frustrating signal integrity issues when dealing with high frequencies in your designs?

Poor signal quality can corrupt critical data and severely cripple the performance of your sensitive electronic systems.

The good news is that pogo pins can be expertly optimized for high-speed signals.

High-frequency pogo pins necessitate controlled impedance, the shortest possible signal paths, and the use of high-quality, low-loss materials.

This careful design approach minimizes signal loss, unwanted reflections, and signal distortion, ensuring clear and reliable transmission for applications like RF communication or high-speed data transfer.

Transmitting high-frequency signals, such as those found in sophisticated RF applications or high-speed data interfaces (like USB 3.0 or HDMI), presents a different challenge compared to standard DC or low-frequency AC.

Standard pogo pins might introduce unacceptable levels of signal loss or distortion.

Therefore, the focus shifts to key engineering considerations:

-

Precise Impedance Matching: This is absolutely paramount.

The characteristic impedance of the pogo pin must meticulously match that of the transmission line (e.g., 50 ohms for RF, or 90-100 ohms for differential pairs) to prevent signal reflections and maximize power transfer.

This involves precise control over the pin’s geometry and the dielectric properties of surrounding insulating materials. -

Minimizing Electrical Length: The shorter the path the electrical signal has to travel through the pogo pin, the better the performance.

This strategy minimizes insertion loss and phase distortion, which are critical for maintaining signal integrity at high frequencies. -

Material Choice for Low Loss: At high frequencies, the "skin effect" becomes a significant factor, meaning that the current tends to flow primarily on the surface of the conductor.

Therefore, materials with high surface conductivity and low dielectric loss are essential for the pin and any insulating components. -

Effective Shielding and Grounding: Proper grounding techniques and, in some cases, incorporating shielding around the pogo pin or its signal path can effectively prevent electromagnetic interference (EMI) and reduce crosstalk between adjacent high-speed signals.

-

Contact Stability and Low Noise: Even minute variations in contact resistance can significantly affect high-frequency signals.

The spring force, contact materials, and the design of the contact point must ensure a stable, low-noise electrical connection throughout the product’s lifecycle.

Designing pogo pins for high-frequency signal transmission requires a holistic approach, focusing on material science, precise geometry, and electrical considerations.

By addressing these factors, engineers can ensure robust and reliable performance for demanding applications.

Why are High-Performance Pogo Pins Essential for Your Business’s Success?

Are standard, off-the-shelf connectors holding back your product’s innovation and potential?

Subpar components can unfortunately lead to poor reliability, customer dissatisfaction, and ultimately, lost customers.

Investing in high-performance pogo pins significantly boosts quality.

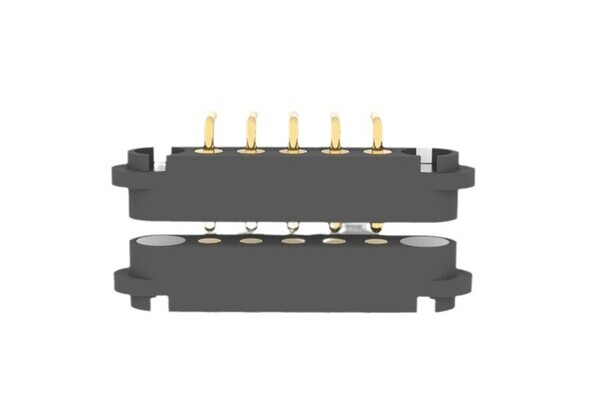

High-performance pogo pins, including advanced magnetic pogo pin connectors, demonstrably enhance product reliability, overall durability, and the end-user experience.

For businesses, this translates directly into fewer product failures, better customer satisfaction scores, and a stronger, more competitive market position, especially when dealing with demanding applications.

In today’s fiercely competitive market, the quality of every single component profoundly matters.

For businesses at the forefront of designing cutting-edge electronics, relying on high-performance pogo pins—whether they are standard spring-loaded pins or innovative magnetic pogo pins-isn’t just a component choice, it’s a strategic imperative.

Here’s why these components are so vital:

-

Enhanced Product Reliability: High-current pogo pins are engineered to prevent overheating and connection failures in critical power applications.

Similarly, high-frequency pogo pins ensure data integrity for seamless and error-free operation.

This inherent reliability translates directly to fewer product returns and reduced warranty claims. -

Improved Durability and Extended Longevity: Pogo pins are inherently designed for a high number of mating cycles.

High-performance versions often utilize superior materials and more robust construction techniques, significantly extending the product’s operational lifespan, even in harsh environmental conditions or with frequent, demanding use. -

Miniaturization and Greater Design Flexibility: Pogo pins, including compact spring-loaded pin connector assemblies, empower engineers to create smaller, more sleek product designs.

Their unique ability to establish reliable connections between irregularly shaped or non-parallel surfaces grants design engineers significantly more freedom and creativity. -

Better Overall User Experience: Consider devices that feature magnetic pogo pin connectors for charging – they offer a satisfyingly simple, "snap-to-connect" experience.

This improved usability can be a key differentiator and a strong selling point, particularly for consumer electronics. -

Crucial Support for Advanced Product Features: As electronic devices become increasingly powerful and data-intensive, the connectors within them must keep pace.

High-performance pogo pins enable critical features like ultra-fast charging, high-speed data transfer (e.g., Thunderbolt, USB-C), and reliable sensor connections in complex IoT devices or life-critical medical equipment.

Partnering with an innovative and customer-focused pogo pin manufacturer ensures you source components that can reliably meet these escalating demands.

What Makes a Provider a Leader in High-Current and High-Frequency Pogo Pins?

Choosing a reliable and expert partner for your critical pogo pin projects is essential.

The wrong choice can, unfortunately, lead to costly project delays and significant quality issues.

Leading providers offer proven expertise and unwavering quality.

Achieving excellence in high-current and high-frequency pogo pin design and manufacturing relies on several key factors.

This includes a strong commitment to advanced research and development, precise manufacturing processes, and stringent quality control protocols.

Such an approach ensures optimal performance and reliability across diverse industrial applications.

A true innovation partner specializes in high-current, high-frequency, and magnetic pogo pins, backed by decades of R&D and cross-industry expertise.

Such solutions empower sectors like automotive, aerospace, medical, and consumer electronics with precision connectivity for evolving technological demands.

Here’s what truly sets a premier pogo pin provider apart:

-

Advanced R&D Capabilities: Independent product and specialized engineering R&D centers are staffed with highly skilled professionals.

These teams are relentlessly exploring new materials, innovative designs, and advanced manufacturing techniques to continuously push the boundaries of pogo pin performance. -

Precision Manufacturing Excellence: Modern facilities, often spanning impressive areas, with dedicated teams of employees, operate fully self-contained and vertically integrated process chains.

This encompasses every stage, from initial product design and precision mold making to automated assembly, comprehensive visual inspection, and final testing, ensuring unparalleled quality at every step. -

Uncompromising Strict Quality Control: Rigorous, multi-layered quality control systems, supported by high-precision inspection equipment, ensure consistent excellence.

Numerous certifications, including ISO9001, IATF16949 for automotive, ISO14001, and ISO45001, along with compliance with global environmental standards like CE, TUV, RoHS 2.0, REACH, Halogen-Free, and California Proposition 65, underscore a steadfast commitment to quality and responsibility. -

Tailored Solutions for Specific Needs: Addressing unique and complex challenges is a core focus.

Whether a specialized magnetic pogo pin connector is needed for a novel charging application, a high-density spring-loaded pin array for data transfer, or a custom solution for a harsh environment, experienced teams are dedicated to providing tailor-made options.

A streamlined custom process, from initial concept and prototyping to efficient bulk delivery, is designed for rapid turnaround and client satisfaction. -

Global Reach and Proven Track Record: Top providers proudly serve major buyer markets across the globe, particularly in consumer electronics, automotive, medical technology, and the rapidly expanding IoT field.

An esteemed list of cooperative partners, including industry giants, stands as a powerful testament to capabilities as a leading and trusted pogo pin provider.

Ultimately, a leading provider is distinguished by its dedication to ongoing innovation and a comprehensive approach to quality.

This ensures that their pogo pin solutions consistently meet the evolving and demanding requirements of various industries globally.

How Do You Choose the Right Manufacturer for High-Performance Pogo Pins?

Feeling overwhelmed by the sheer number of pogo pin supplier choices available in the market?

Making a poor choice in this critical area can unfortunately impact your product quality, project timelines, and even your budget.

The key is to focus on a few vital criteria for selection.

When selecting a pogo pin manufacturer, especially for high-performance needs, prioritize those with proven expertise, robust R&D capabilities, comprehensive quality control systems, strong customization abilities, and reliable, responsive support.

Always look for relevant industry certifications and a transparent, well-documented manufacturing process.

Selecting the right pogo pin manufacturer is absolutely crucial for your project’s ultimate success, particularly when your application demands high-performance characteristics like high current capacity or excellent high-frequency signal integrity.

As someone who has navigated this industry for many years, I always advise potential pogo pin buyers to look beyond just the initial price tag.

Here are some critical factors to consider when you’re searching for a premium pogo pin manufacturer or a specialized magnetic pogo pin supplier:

| Criteria | Why It Matters for High-Performance Pogo Pins | What to Look For in a State-of-the-art Pogo Pin Manufacturer |

|---|---|---|

| Deep Technical Expertise | Designing effectively for high current or high frequency requires highly specialized knowledge and experience. | A strong, experienced R&D team; a portfolio showcasing success with similar demanding applications. |

| Comprehensive Quality Certs | These ensure consistent, repeatable manufacturing processes and reliably high product quality. | ISO9001 (general quality), IATF16949 (critical for automotive), ISO14001 (environmental management). |

| Strong Customization Ability | Standard off-the-shelf pogo pin solutions may not always adequately fit unique or demanding applications. | In-house design teams, rapid prototyping capabilities, flexibility in Minimum Order Quantities (MOQs), diverse material options. |

| Advanced Material Knowledge | The choice of materials is absolutely key for conductivity, mechanical durability, and signal integrity. | Full transparency about materials used (e.g., plunger, barrel, spring, plating); ability to suggest optimal alternatives. |

| Robust Testing Capabilities | This verifies crucial performance claims (e.g., current rating, impedance matching, cycle life, corrosion resistance). | Access to in-house testing labs; provision of detailed, comprehensive test reports for their pogo pin connector products. |

| Supply Chain Control & Transparency | This directly impacts lead times, ensures quality consistency, and demonstrates the ability to scale production. | Vertically integrated manufacturing processes where possible; clear, proactive communication regarding supply chain status. |

| Responsive Support & Clear Communication | Essential for efficiently resolving any technical issues and ensuring a smooth, productive partnership. | Easily accessible and responsive customer service; clear, concise technical support from knowledgeable engineers. |

For high-performance pogo pins, a thorough evaluation of a manufacturer’s expertise, quality adherence, and support capabilities is more important than just the initial price.

This careful consideration helps ensure long-term product success.

Conclusion

High-performance pogo pins are vital for modern electronics, enabling robust power delivery and clear high-frequency signals.

Choosing a knowledgeable and experienced pogo pin manufacturer like CTP ensures quality, reliability, and innovation for your designs.

Ready to elevate your product’s performance and reliability with superior pogo pin technology?

As a leading and innovative pogo pin manufacturer, CTP offers a wide range of standard and custom solutions tailored to your specific high-current and high-frequency needs.

We invite you to visit our homepage to learn more about our capabilities!