Facing issues with connector breakdowns in your critical projects?

Uncertainty about component reliability can jeopardize project timelines and product performance.

Let me explain why pogo pins might be the robust solution you need.

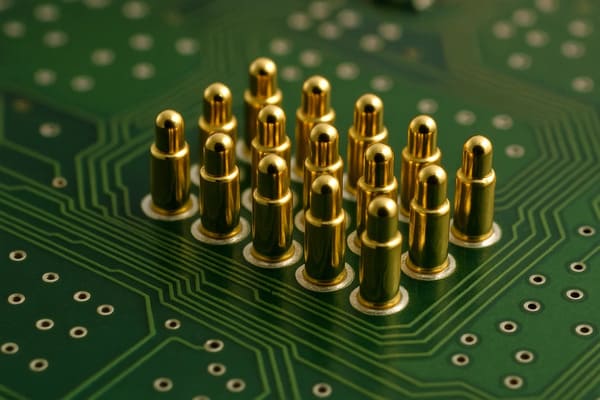

Pogo pins are ideal for high-durability needs due to their robust spring-loaded design and precision manufacturing.

They ensure stable electrical connections and a long operational life, even with frequent use or in harsh conditions.

This makes them highly reliable for demanding applications.

To understand why pogo pins excel in durability, it’s helpful to explore the factors contributing to their robust design and extended lifespan, guiding you in selecting optimal components for critical uses.

What Makes Pogo Pins Mechanically Durable?

Are you concerned about connectors wearing out from constant plugging and unplugging?

Mechanical stress is a real factor, potentially leading to failure.

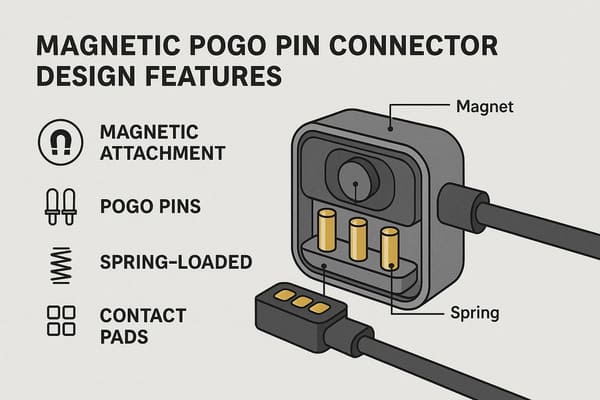

Let’s see how well-designed pogo pins, including magnetic pogo pin connectors, handle this challenge.

Pogo pins achieve mechanical durability through their precise construction and robust materials.

They are engineered to withstand thousands, often tens of thousands, of mating cycles.

This design ensures consistent performance and minimal wear over time.

While the general durability of pogo pins is clear, it’s worth delving into the specific elements that contribute to their mechanical resilience.

Examining these key factors will provide a deeper insight into their robust performance.

Key Factors of Pogo Pins in Mechanical Strength

Understanding what contributes to mechanical endurance helps in selecting the right pogo pin for an application.

Here’s a breakdown of the key elements that contribute to their robust performance:

- High Cycle Life: Pogo pins are designed to withstand repeated compression.

Standard pins often achieve 10,000-50,000 cycles, while specialized designs can exceed 100,000 cycles.

This makes them ideal for devices requiring frequent connections, like medical wearables or consumer electronics charging ports. - Robust Materials: The choice of materials for the barrel, plunger, and spring is critical.

Strong, wear-resistant alloys ensure the pin withstands physical stress over its intended lifespan. - Precision Manufacturing: Tight tolerances and smooth finishes minimize friction and wear during operation.

This precise engineering is key to long-term reliability, ensuring consistent performance. - Consistent Spring Force: The internal spring provides the necessary contact force for a reliable connection while being designed to maintain its integrity over many cycles.

- Design Features: Elements like internal guides or specific tip shapes can enhance alignment and reduce wear during mating.

Magnetic pogo pins further simplify connection and reduce stress by guiding alignment automatically.

By focusing on these design and material considerations, pogo pins deliver exceptional mechanical durability, ensuring reliable performance in demanding applications where frequent connections are essential.

How Do Materials and Plating Affect Pogo Pin Reliability and Lifespan?

Choosing the wrong materials can compromise conductivity or lead to corrosion, causing early failures.

Environmental exposure adds another layer of challenge.

Let’s look at how material science impacts pogo pin connector reliability.

Selecting appropriate base materials and surface plating is fundamental to pogo pin durability and long-term reliability.

These choices directly influence electrical performance, corrosion resistance, and the overall lifespan of the spring loaded pin.

Materials like beryllium copper and stainless steel are preferred for their electrical properties and endurance.

Gold or nickel plating enhances conductivity and corrosion resistance.

The performance and longevity of pogo pins are significantly affected by the materials chosen for their construction and surface finishes.

Understanding these material aspects is crucial for optimizing their function and ensuring sustained reliability.

Material and Plating Considerations With Pogo Pins

The choice of materials in a pogo pin connector is crucial for its performance across various environments and applications.

Engineers carefully select these materials to meet specific operational demands:

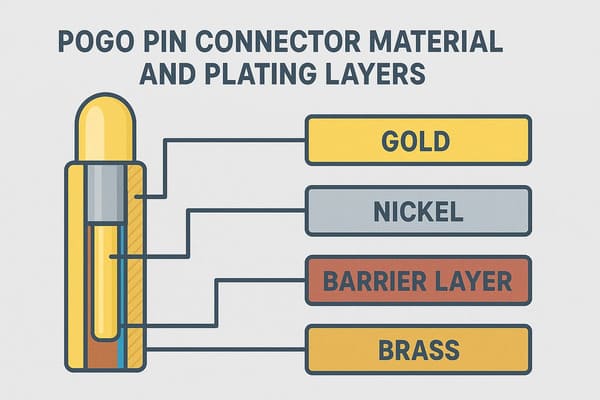

- Base Materials: Copper alloys (like brass or beryllium copper) are common due to their good conductivity and mechanical properties.

However, copper can oxidize, so plating is essential for the reliability of pogo pins, especially in less controlled environments. - Plating Layers: Plating protects the base material and enhances electrical contact.

- Nickel: Often used as an underlayer, nickel provides a hard, corrosion-resistant barrier.

It’s durable but less conductive than gold. - Gold: Typically the top layer, gold offers excellent conductivity and superior resistance to corrosion and tarnishing.

It’s ideal for low-voltage signals and high-reliability applications but increases the cost of pogo pins.

- Nickel: Often used as an underlayer, nickel provides a hard, corrosion-resistant barrier.

- Environmental Resistance: Materials must withstand factors like humidity, temperature fluctuations, and exposure to chemicals or dust.

Proper material selection and plating ensure pogo pin’s reliability in diverse settings, from consumer devices to industrial or automotive applications. - Specialized Materials: For unique needs, other materials or platings like palladium might be used.

Ultimately, balancing these material and plating considerations is vital to ensure pogo pins deliver consistent, long-lasting performance in their intended applications.

Can Pogo Pins Maintain Consistent Electrical Performance?

Worried about intermittent connections or signal loss in your devices?

Unstable electrical performance can undermine functionality and reliability.

Let’s examine how spring loaded pin connectors ensure consistent electrical flow.

Yes, pogo pins can maintain consistent electrical performance.

Their design, which includes a plunger, barrel, and spring, ensures reliable contact under mechanical stress.

Quality materials and precise manufacturing contribute to stable electrical connections and signal integrity over time.

To further understand how these connectors achieve such dependable results.

let’s delve into the specific design elements and considerations that ensure lasting electrical stability.

Ensuring Electrical Stability With Using Pogo Pin

Maintaining signal integrity and power delivery is crucial.

Here’s how pogo pins achieve consistent electrical performance, making them a trusted choice for buyers:

- Stable Contact Resistance: The spring mechanism of pogo pin ensures continuous pressure between the plunger and the contact pad (and internally between plunger and barrel).

This maintains a low and stable contact resistance, vital for reliable data and power transmission. - High-Conductivity Path: Using conductive base materials like copper alloys, often plated with gold, minimizes resistance and prevents signal degradationor excessive voltage drop.

This is crucial whether transmitting tiny signals or higher currents. - Appropriate Current Handling: Pogo pins can be designed to handle specific current and voltage requirements, from milliamps for signals to several amps for power charging.

A high-quality magnetic pogo pin connector supplier like CTP ensures pins meet the specified electrical load without degrading. - Durable Contact Surface: The plating (usually gold) on the contact surfaces resists wear and corrosion, maintaining excellent conductivity over thousands of mating cycles.

- Design Variations: Different pin tip designs (flat, pointed, rounded) can optimize contact for specific needs, such as high current transfer (flat head) or penetrating surface contaminants (pointed head).

In summary, the robust design, material selection, and precise manufacturing of pogo pins ensure stable contact resistance, high conductivity, and durability, all contributing to reliable electrical performance across diverse applications.

Conclusion

In conclusion, pogo pins, including magnetic pogo pin variants, are indeed reliable enough for demanding applications.

Their durability stems from thoughtful design, careful material selection, and precision manufacturing processes.

Need reliable connectors? Contact us at CTP today.