Are you tired of dealing with shaky connections or sudden product failures?

I know how frustrating it is when a tiny part like a pogo pin causes major headaches for your business.

These small components can make or break your product’s reliability.

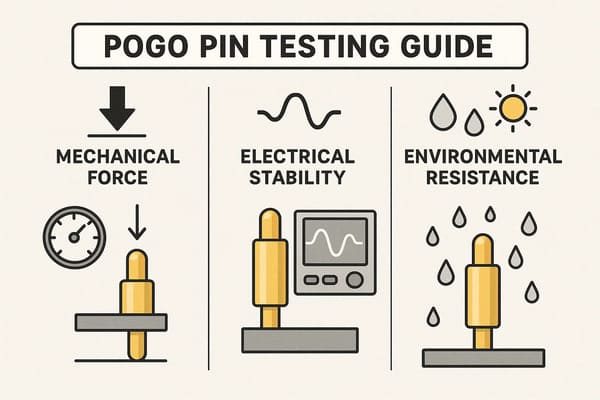

Pogo pin testing ensures consistent performance, durability, and quality in every connection.

This process examines mechanical force, electrical stability, and environmental resistance.

Key steps include initial qualification, production lot testing, life cycle simulation, and failure analysis.

Proper pogo pin testing prevents intermittent issues and builds reliable products.

Now that you’ve got the basics, let’s explore why pogo pins matter and how proper testing can transform your production process.

Stick with me to uncover actionable insights for your next project.

What Are Pogo Pins and Why Do They Matter in Your Products?

Have you ever wondered how tiny connectors keep your electronics running smoothly?

I’ve seen firsthand how a small failure in a pogo pin can halt an entire production line.

It’s a pain no manufacturer wants to face.

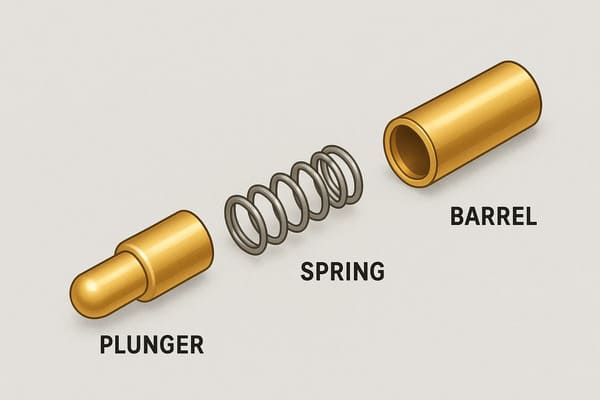

Pogo pins are small, spring-loaded electrical connectors used for reliable contacts in electronic devices.

They consist of a plunger, barrel, and spring, ensuring stable connections between components.

These pins are vital in consumer electronics, automotive, and medical fields due to their compact size and suitability for high-density designs.

Let’s dive into where they shine and why testing them is non-negotiable.

Keep reading to see how they impact your bottom line.

Once we understand their role, we can focus on specific applications.

I’ll show you how a trusted pogo pin supplier like us ensures these tiny parts deliver big results across various fields.

Pogo Pin Applications and Testing Needs

I remember a client in the wearable tech space who faced constant charging issues.

It turned out their magnetic pogo pin connectors were failing due to poor durability.

That’s when I realized how critical testing is.

Let’s look at where pogo pins are used and why their quality can’t be ignored:

- Consumer Electronics: They’re in smartphones, tablets, and smartwatches for charging and data transfer.

A reliable pogo pin connector ensures your customers don’t face downtime. - Automotive Industry: Used in electric vehicle charging and onboard electronics.

Precision pogo pin manufacturers test for extreme conditions to prevent failures. - Medical Devices: Found in portable equipment where stable connections save lives.

High-quality spring loaded pin suppliers focus on consistency. - Wearables and IoT: Smart devices need compact, durable pins for seamless operation.

Testing by an innovative pogo pin supplier catches flaws early.

Pogo pins are essential for modern product reliability.

Understanding their applications and rigorous testing is crucial.

This ensures consistent performance in critical fields like medical and automotive electronics.

Investing in quality connections truly benefits product longevity.

How Do We Test Pogo Pin Performance with Precision?

Are you struggling to pinpoint why your product connections fail?

I’ve been there, troubleshooting with a client whose automotive project kept shorting out.

The culprit? Untested pogo pins.

Precision pogo pin performance is guaranteed through rigorous testing.

We confirm mechanical strength (insertion force), electrical conductivity (resistance), and durability against environmental factors like heat and moisture.

Our connectors ensure lasting reliability across all applications, from smart homes to aerospace.

Let’s move forward to see how our advanced testing capabilities set us apart. You’ll want to know how we tackle every challenge.

Now, I’ll break down our specific testing methods under mechanical, electrical, and environmental categories.

As a precision spring loaded pin manufacturer, we leave no stone unturned.

Mechanical Force and Dimensional Accuracy

Insertion and Extraction Force: This test checks the pressure needed to connect and disconnect a pogo pin.

Too much force damages parts; too little risks poor contact.

Our skilled team uses automatic machines to measure this with pinpoint accuracy, ensuring every durable pogo pin connector meets your needs.

Dimensional Quality Control: Size matters. Even a tiny deviation can disrupt the assembly.

We use 2D projectors for optical measurement, confirming every dimension.

This is how a reliable pogo pin supplier prevents costly production errors.

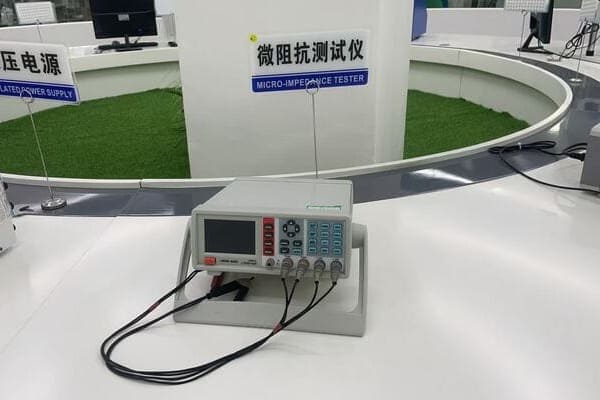

Electrical Conductivity and Stability

Micro-Impedance Testing: Low resistance means better signal flow. High resistance leads to power loss.

Our engineers use tools with 0.1mΩ resolution for micro-impedance tests, ensuring ISO-certified quality for automotive pogo pin connectors.

Current Rating and Temperature Rise: Overheating can fry components.

We test pins at 15A and 150°C using ISO-certified equipment, meeting IEC 60512 standards.

This ensures thermal stability for products from a top magnetic pogo pin supplier.

Voltage Regulator Test: Stable voltage under load is crucial.

Our technicians use multimeters to keep dropout below 5V, verifying efficiency for automotive electronics as a premier spring loaded pin connector manufacturer.

Environmental Durability and Material Compliance

Thermal Shock and Stability: Rapid temperature swings can crack connections.

We test from -40°C to 150°C with ISO-certified machines, ensuring compliance with IEC 60512.

Constant humidity tests at 95% prove durability for an experienced pogo pin connector supplier.

Corrosion Resistance: Harsh environments corrode metal.

Our salt mist testers simulate these conditions, ensuring RoHS/REACH compliance for automotive applications.

This is a must for a specialized magnetic pogo pin connector manufacturer.

Material Composition and Film Thickness: Restricted substances like lead are a no-go.

We use XRF analyzers to check compliance and measure coating thickness for lasting performance, a hallmark of an advanced pogo pin manufacturer.

Comprehensive testing ensures pogo pins meet strict quality standards.

These meticulous evaluations verify performance and reliability for diverse applications.

By focusing on mechanical, electrical, and environmental aspects, product integrity is maintained.

What Are the Essential Pogo Pin Testing Methodologies?

Do connection failures keep slowing down your production?

I recall a time when a batch of untested pins cost a client thousands in rework.

That’s a lesson I’ll never forget.

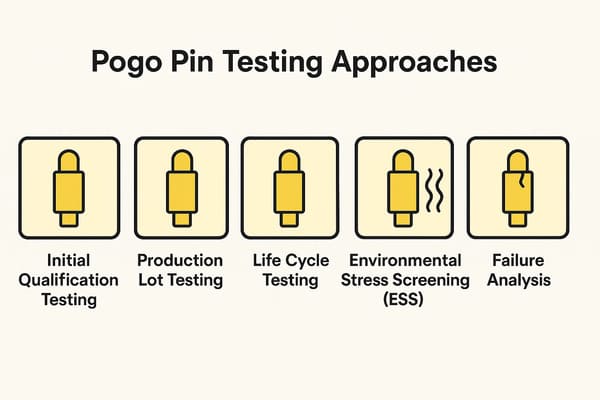

Essential pogo pin testing includes initial qualification for baseline electrical and mechanical properties.

Production lot testing uses sampling to catch defects.

Life cycle testing simulates long-term use, and environmental stress screening combines heat, humidity, and vibration.

Failure analysis, using tools like SEM and X-ray, identifies root causes for reliable connectors.

Let’s see how these methods build reliability.

You’ll want to stick around for practical insights.

I’ll detail each approach, showing how a customer-focused pogo pin connector manufacturer uses them to ensure flawless products for B2B partners.

Breaking Down Testing Approaches

- Initial Qualification Testing: We inspect the first articles to confirm electrical and mechanical specs.

This sets a benchmark for every batch. - Production Lot Testing: Sampling and statistical process control help us monitor quality during mass production.

It’s how we avoid surprises. - Life Cycle Testing: We simulate long-term use in a short time.

This accelerated testing predicts how pins hold up over the years.

- Environmental Stress Screening (ESS): We combine temperature, humidity, and vibration to push pins to their limits.

Only the toughest pass. - Failure Analysis: If something goes wrong, we dig deep with optical tools, SEM, and X-ray to understand why.

This prevents repeats.

These rigorous testing methods are crucial for pogo pin connector reliability.

They ensure components withstand varied conditions, preventing unexpected failures.

Implementing these practices can significantly enhance product performance and longevity.

What Are the Best Practices for Ensuring Pogo Pin Quality?

Are you losing sleep over product recalls due to connector issues?

I’ve worked with a medical device maker who faced this nightmare.

Untested pogo pins were the root cause.

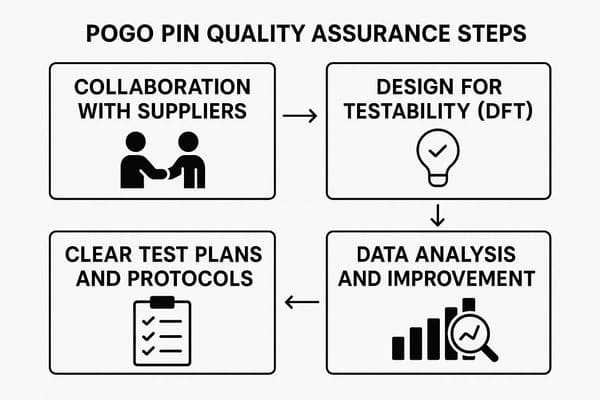

Ensuring pogo pin quality involves clear steps.

It begins with defining specifications and auditing supplier processes.

Products should be designed with testability in mind from the outset.

Detailed test plans, including acceptance criteria and sequences, are essential.

Utilizing test data for continuous design and manufacturing improvement also enhances quality.

Let’s explore how to put these into action.

You’ll find value in these tips for your next project.

I’ll now expand on each practice, showing how a premium spring loaded pin connector supplier embeds quality at every step for industries like IoT and automotive.

Practical Steps for Quality Assurance

- Collaboration with Suppliers: I insist on clear specs and regular audits. Open communication ensures everyone is on the same page.

This builds trust with every pogo pin buyer. - Design for Testability (DFT): Start with testing in mind.

I work with design teams to ensure pins are accessible for checks. It saves time later. - Clear Test Plans and Protocols: Define what “pass” means. Set test sequences and collect data systematically.

It’s how a precision-made pogo pin manufacturer avoids guesswork. - Data Analysis and Improvement: Use test results to tweak designs. I’ve seen small changes cut failure rates by half.

Continuous feedback keeps us ahead.

Here’s a quick look at how we structure collaboration with B2B clients:

| Aspect | Our Approach | Benefit to You |

|---|---|---|

| Supplier Communication | Weekly updates and spec reviews | No surprises in production |

| Design Input | Early testing considerations | Faster troubleshooting |

| Test Criteria | ISO and IEC standards | Globally accepted quality |

| Data Use | Real-time adjustments to process | Fewer defects, better products |

These steps aren’t just theory.

They’ve helped clients in consumer electronics and aerospace avoid costly failures.

Consistent practices, like thorough design and data analysis, are vital.

They ensure high-performance components and foster customer confidence.

How Can Pogo Pin Testing Boost Your Product Reliability?

Have You ever had a product fail at the worst possible time?

I once had a client in smart home tech whose devices kept dropping connections.

After implementing strict pogo pin testing, their return rate dropped by 70%.

Pogo pin testing boosts product reliability by catching issues before customer delivery.

Mechanical tests verify that pins withstand stress without breaking.

Electrical checks confirm stable power and signal transmission.

Environmental trials ensure pins endure tough conditions, minimizing recalls.

Let’s see why this matters to your business.

Stay with me for deeper insights.

I’ll explain how testing directly improves outcomes, drawing from a durable spring loaded pin supplier serving global markets.

Pogo Pin Testing Impacts on Product Success

- Reduces Failures: Catching weak pogo pin interconnections early means significantly fewer product failures in the field.

This proactive approach can save businesses, especially in IoT, from dealing with frustrated end-users and negative feedback. - Builds Trust: Consistent product quality is essential for earning and maintaining customer confidence.

When products reliably perform as expected, it naturally fosters repeat business and helps build strong, long-term partnerships in the industry. - Saves Costs: Addressing potential issues during the manufacturing and testing phases is far more economical than managing product recalls after launch.

Investing in robust pogo pin testing procedures should be viewed as a cost-saving measure, not an additional expense. - Meets Regulations: Many industries, particularly those like medical devices, have strict compliance requirements.

Implementing certified testing processes helps ensure that products meet these necessary standards and regulatory demands, providing peace of mind.

Let’s look at a comparison of tested vs. untested pins in critical applications:

| Factor | Tested Pogo Pins | Untested Pogo Pins |

|---|---|---|

| Connection Stability | 99.9% uptime in trials | Frequent drops and failures |

| Lifespan | Up to 1 million cycles | Often fails below 100,000 cycles |

| Environmental Resistance | Survives -40°C to 150°C | Cracks under thermal shock |

| Customer Returns | Below 1% return rate | High returns and complaints |

Ultimately, prioritizing thorough testing of these crucial pogo pin components pays dividends.

It enhances product lifespan, strengthens consumer confidence, and reduces operational burdens.

This strategic investment in quality ensures long-term success and market credibility.

What Challenges Do Pogo Pins Face in Harsh Environments?

Are harsh conditions ruining your product performance?

I recall helping a robotics firm whose pogo pins failed in humid settings.

It was a wake-up call on environmental impact.

Pogo pins face significant challenges in harsh environments, including moisture, salt, and extreme temperatures.

High humidity and salt exposure can lead to corrosion, compromising material integrity and electrical contacts.

Rapid temperature fluctuations and constant vibration also stress these components, potentially causing connection disruptions and overall product failure.

Let’s tackle how to overcome these hurdles.

You’ll find this useful for demanding applications.

I’ll now go deeper into environmental testing, showing how an eco-friendly pogo pin manufacturer ensures performance under any condition for B2B buyers.

Overcoming Environmental Stressors

- Moisture Resistance: High humidity levels can corrode sensitive components over time.

Testing involves exposing pins to 90-95% humidity at 40°C for 96 hours.

This rigorous process verifies that the pins can reliably function in consistently wet environments. - Salt Spray Resistance: Salt fog environments, common in coastal or industrial areas, can induce galvanic corrosion.

Components undergo 48 hours of salt spray exposure, then checked for any signs of corrosion. This ensures they maintain reliability in harsh, saline conditions. - Temperature Extremes: Components must withstand a wide range of temperatures, from freezing -65°C to scorching 200°C.

Thermal shock tests confirm their stability through rapid temperature swings.

This is crucial for applications like aerospace, where conditions vary drastically. - Vibration and Shock: Constant vibration and sudden impacts, typical in transportation and heavy machinery, can loosen connections.

Testing involves evaluating peak acceleration and pulse shape.

This helps prevent breaks in electrical continuity, ensuring stable operation.

Here’s a breakdown of environmental tests we conduct:

| Test Type | Conditions | Purpose |

|---|---|---|

| Humidity Test | 90-95% RH, 40±20°C, 96 hours | Check insulation in wet settings |

| Salt Spray Test | Salt fog, controlled temp, 48 hours | Assess corrosion in salty areas |

| Thermal Shock | -40°C to 150°C, rapid cycles | Ensure material withstands changes |

| Vibration Test | Defined acceleration, pulse duration | Confirm stability under movement |

Ultimately, understanding and addressing these environmental factors through rigorous testing is vital.

Such proactive measures ensure component longevity and optimal product functionality.

This approach minimizes potential failures, fostering greater confidence in device performance across diverse operating conditions.

Conclusion and Call to Action

I’ve walked you through pogo pin testing, from basics to advanced methods.

Proper testing ensures performance, durability, and quality, saving you from costly failures.

As Steven from CTP in China, I invite you to explore our solutions at homepage.

Need reliable pogo pins or magnetic connectors?

Reach out via our contact page for customized B2B support.