Ever wonder why your device loses connection at the worst time?

I’ve felt that frustration when a tiny pogo pin fails.

These connectors power many electronics, yet their issues can halt everything from charging to testing.

Pogo pins commonly fail due to wear, corrosion, and spring fatigue.

Wear occurs from repeated compression cycles, while corrosion arises in harsh environments, degrading conductivity. Spring fatigue leads to inconsistent contact force.

Addressing these issues involves selecting durable materials, applying protective coatings, and optimizing spring design for specific applications.

Let’s dive deeper.

I’ve got insights to share on why pogo pins fail and how a trusted pogo pin manufacturer can help B2B buyers avoid costly downtime.

What Goes Into Understanding Pogo Pin Design and Function?

Have you ever wondered why small connectors matter so much to your device’s performance?

I’ve explored this as a premier pogo pin connector supplier.

Pogo pins, or spring-loaded connectors, are vital for reliable electrical contacts.

Understanding pogo pin design involves three components: the plunger, barrel, and spring.

The plunger ensures electrical contact.

The barrel guides the plunger, and the spring provides the necessary force for connection.

This assembly allows reliable electrical pathways despite minor misalignments, crucial for various electronic applications.

Reliability is everything. I’ve worked with clients in the aerospace and medical fields who can’t afford a single failure.

A dependable pogo pin connector manufacturer ensures these pins perform under pressure, whether in a smartphone or an industrial test fixture.

Without reliability, devices fail, costs rise, and trust is lost.

Let’s keep going. I’ll show you the common failures that threaten this reliability.

What Are the Most Common Pogo Pin Failures?

Have you experienced a device unexpectedly stop functioning?

Often, the cause traces back to a pogo pin.

These issues can disrupt various electronic applications.

Understanding the common problems is essential for maintaining device performance.

Pogo pin failures typically occur due to mechanical wear, electrical issues, or environmental factors.

Mechanical wear includes issues like bent plungers or weakened springs.

Electrical problems often involve high resistance or intermittent connections.

Environmental damage can result from corrosion or contamination.

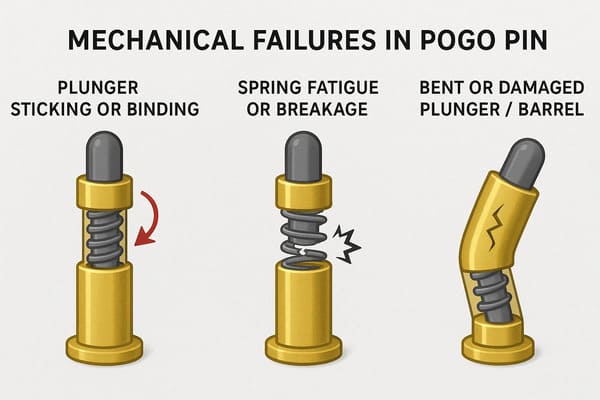

Mechanical Wear and Tear in Pogo Pins

- Plunger Sticking or Binding: This occurs when dust, debris, or misalignment restricts pin movement.

Poor lubrication or excessive side force can also contribute.

This leads to intermittent or no contact, significantly reducing the pogo pin’s lifespan. - Spring Fatigue or Breakage: Over-compression, inadequate materials, or exposure to high temperatures and excessive cycles can degrade the spring.

When the spring fails, contact force diminishes, resulting in open circuits. - Bent or Damaged Plunger/Barrel: Misalignment during connection or rough handling can deform components.

Impacts also play a role, leading to sticking, short circuits, or complete loss of contact.

Here’s a quick table to summarize:

| Failure Type | Causes | Impact |

|---|---|---|

| Plunger Sticking/Binding | Contamination, Misalignment | Intermittent/No Contact, Short Life |

| Spring Fatigue/Breakage | Over-Compression, Poor Material | Loss of Force, Open Circuits |

| Bent Plunger/Barrel | Misalignment, Impact | Sticking, Shorts, No Contact |

Electrical Failures Affecting Pogo Pin Performance

- High Contact Resistance: Oxidation, contamination, or worn plating can raise resistance.

Insufficient contact force also contributes. This causes voltage drops, heat buildup, and signal loss. - Intermittent Contact: Vibration, weak spring force, or bent pins can disrupt connections.

Contamination and plunger sticking worsen it. The result is unreliable data or power interruptions. - Short Circuits: Bent pins touching each other, solder bridges, or conductive debris can create shorts.

This can lead to device malfunctions or even damage.

Here’s a summary table:

| Electrical Failure | Causes | Impact |

|---|---|---|

| High Contact Resistance | Oxidation, Worn Plating | Voltage Drop, Signal Loss |

| Intermittent Contact | Vibration, Weak Spring Force | Unreliable Data/Power |

| Short Circuits | Bent Pins, Conductive Debris | Malfunction, Device Damage |

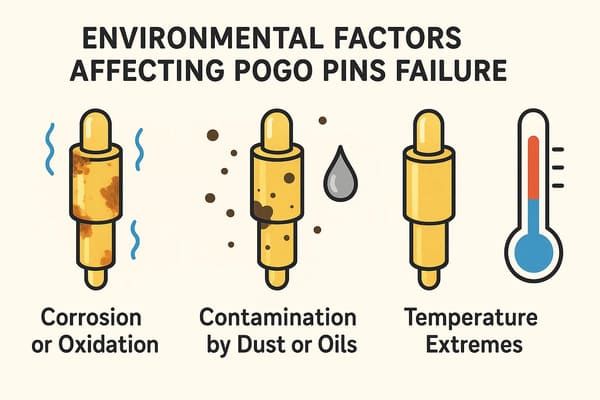

Environmental Factors Impacting Pogo Pin Reliability

- Corrosion or Oxidation: Humidity, harsh chemicals, or salty environments can cause rust and oxidation.

Improper storage exacerbates this, increasing resistance and disrupting contact. - Contamination by Dust or Oils: Exposure to dirty environments or improper handling introduces debris. This causes sticking and high resistance, leading to intermittent contact.

- Temperature Extremes: Operating outside specified temperature ranges can cause materials to expand or contract.

This leads to misalignment or changes in spring force, impacting performance.

Here’s a quick reference:

| Environmental Factor | Causes | Impact |

|---|---|---|

| Corrosion/Oxidation | Humidity, Chemicals | High Resistance, Unreliable Contact |

| Contamination | Dust, Poor Handling | Sticking, Intermittent Contact |

| Temperature Extremes | Outside Specified Range | Misalignment, Force Changes |

These mechanical, electrical, and environmental issues highlight the importance of robust design and proper handling. Addressing them proactively can significantly extend the lifespan of pogo pin. Selecting high-quality materials and ensuring correct alignment are crucial steps.

How Can You Solve and Prevent Pogo Pin Failures?

Ever felt stuck wondering how to fix a failing connector or stop it from happening again?

I’ve been in that spot, and as a precision-made pogo pin connector supplier, I’ve gathered solutions that work.

Let’s tackle how to address and prevent pogo pin failures for B2B applications.

Pogo pin failures can be mitigated through strategic design, precise manufacturing, and diligent maintenance practices.

Preventing issues involves selecting durable materials and robust designs, crucial for applications where uninterrupted performance is essential.

Addressing these aspects ensures reliable and long-lasting connections in various electronic systems.

Keep reading. I’ve got practical tips split into design, manufacturing, and maintenance areas.

You’ll see how a customer-focused pogo pin supplier can make a difference in your project’s success.

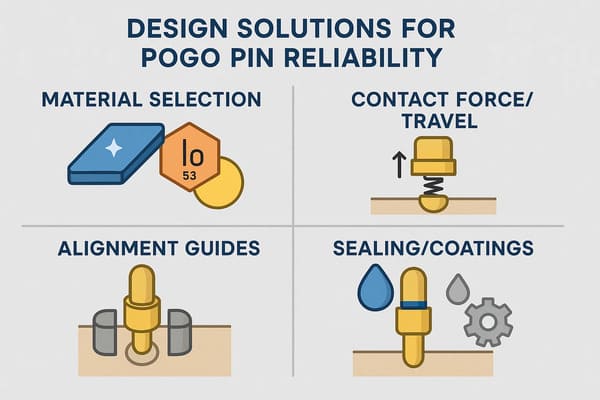

Design and Selection Considerations for Pogo Pins

- Choosing the Right Pogo Pin: Material choice is crucial. Gold plating offers corrosion resistance, while the appropriate spring material ensures durability.

Consider matching contact force to application needs—higher for industrial uses and lighter for wearables.

Travel distance should allow compression without overstress. - Proper Mating Alignment: Incorporating guides and fixtures in the design helps ensure accurate alignment.

Performing tolerance stack-up analysis can account for manufacturing variations.

This approach helps prevent issues like bending and sticking. - Environmental Sealing: For harsh conditions, consider using IP-rated connectors to block dust and moisture.

Applying protective coatings adds an extra layer of defense against corrosion.

Here’s a summary table:

| Design Aspect | Solution | Benefit |

|---|---|---|

| Material Selection | Gold Plating, Strong Springs | Corrosion Resistance, Durability |

| Contact Force/Travel | Match to Application | Prevents Overstress, Ensures Contact |

| Alignment Guides | Fixtures, Tolerance Analysis | Avoids Bending, Sticking |

| Sealing/Coatings | IP-Rating, Protective Layers | Protects Against Environment |

Manufacturing and Assembly Best Practices

- Cleanroom Assembly: Assembling pins in a controlled environment reduces contamination risks.

Dust and debris during production can lead to sticking later. - Proper Soldering Techniques: Correct soldering prevents wicking and ensures strong joints.

Poor soldering can lead to shorts or weak connections. - Quality Control Testing: Implementing checks for contact resistance, spring force, and visual defects before deployment is key.

Catching issues early can prevent later complications.

Here’s a quick table:

| Practice | Action | Outcome |

|---|---|---|

| Cleanroom Assembly | Controlled Environment | Minimizes Contamination |

| Soldering Techniques | Prevent Wicking, Strong Joints | Avoids Shorts, Weak Connections |

| Quality Control | Test Resistance, Force, Defects | Catches Issues Early |

Maintenance and Troubleshooting Tips for Pogo Pins

- Regular Cleaning: Use appropriate solvents to remove contaminants like dust or oils. This helps prevent sticking and resistance buildup.

Schedule cleanings after heavy use cycles for industrial applications. - Visual Inspection: Regularly check for bent pins, wear, or corrosion.

Spotting damage early avoids bigger issues.

Implement quick checks during assembly in consumer electronics. - Replacement Timing: Know when a pin can’t be fixed. If wear or damage is severe, replace it.

Swapping pins before failures disrupt workflows is crucial in testing setups. - Lubrication (If Applicable): Some pogo pins benefit from specialized lubricants to reduce friction.

This is useful for high-cycle applications where sticking might be a recurring problem.

Here’s a reference table:

| Maintenance Task | Method | Purpose |

|---|---|---|

| Cleaning | Appropriate Solvents | Removes Contamination |

| Visual Inspection | Check for Damage, Wear | Prevents Major Failures |

| Replacement | Swap Damaged Pins | Maintains Reliability |

| Lubrication | Use Specialized Products | Reduces Friction, Sticking |

By focusing on these practical steps—from careful design and manufacturing to consistent maintenance—you can significantly enhance the reliability and lifespan of your pogo pins.

Proactive management of these components ultimately leads to more stable and efficient electronic systems, minimizing costly downtime.

What Can We Learn from Real-World Pogo Pin Failures?

Real-world examples bring failures to life. Experiences from various projects have taught valuable lessons regarding common issues.

Understanding these common failure modes is crucial for ensuring the reliable performance of pogo pins.

Real-world challenges offer invaluable insights.

As a leading pogo pin manufacturer, I’ve directly addressed complex issues that have significantly shaped our approach to product development.

Allow me to illustrate with a recent example.

A wearable tech client’s smartwatch docking station frequently lost connection. Returns surged due to a plunger sticking from assembly contamination.

We resolved this by implementing cleanroom assembly and adding a protective coating, eliminating the issue and improving user feedback.

These experiences underscore the critical importance of proactive problem-solving.

As a dedicated spring-loaded pin supplier, I leverage such real-world learnings to continuously enhance our solutions for B2B partners across the automotive and smart home industries, ensuring long-term reliability and performance.

Conclusion

I’ve covered the common failures of pogo pins and shared actionable solutions to prevent them.

From mechanical wear to environmental damage, the right design and care make all the difference.

At CTP, we’re a trusted pogo pin manufacturer ready to help.

Visit our home page or contact us to ensure reliable connections for your next project.